Speed amplification combined damping device and eddy current damping wall

A technology of eddy current damping and damping devices, which is applied in building types, building components, and earthquake resistance, can solve the problems of small displacement between building floors and increase energy consumption efficiency of damping walls, and achieve the effect of increasing energy consumption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

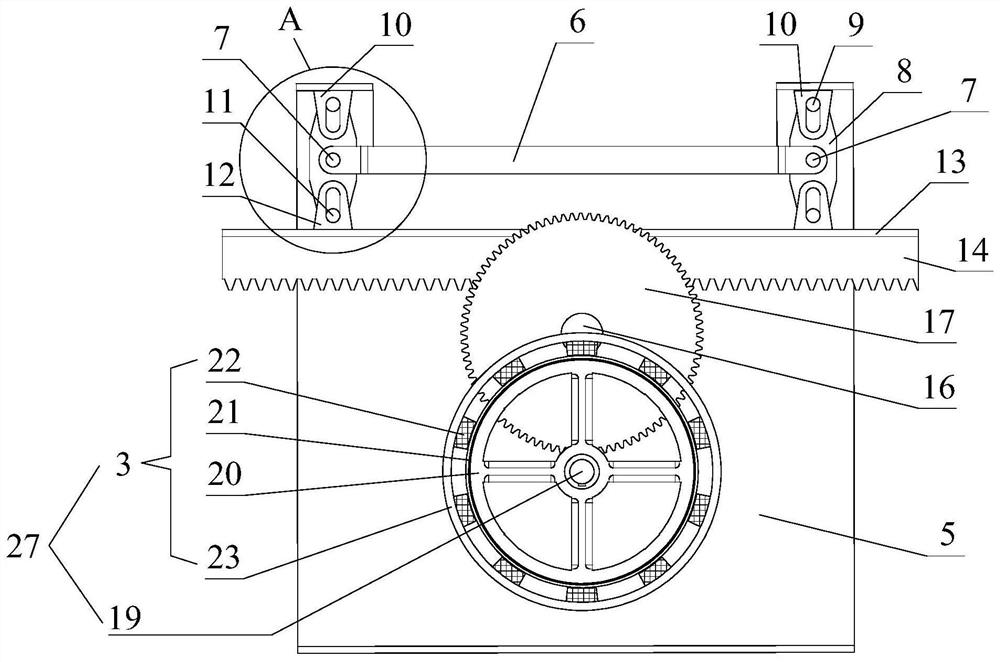

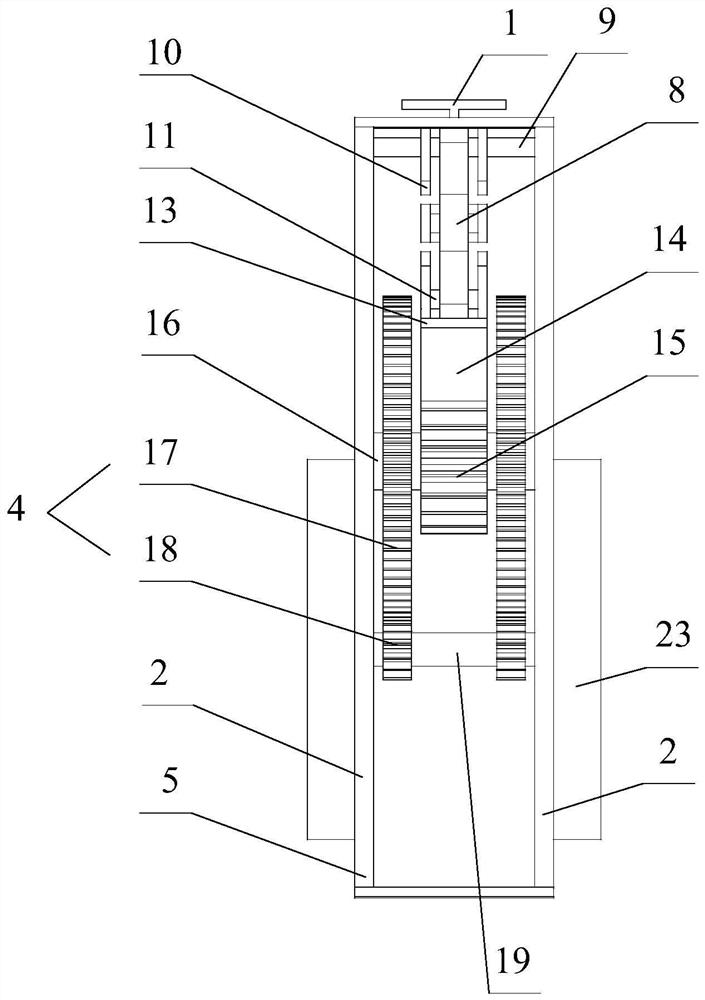

[0063] Such as Figure 1-3 As shown, a speed amplification combined damping device described in this embodiment includes,

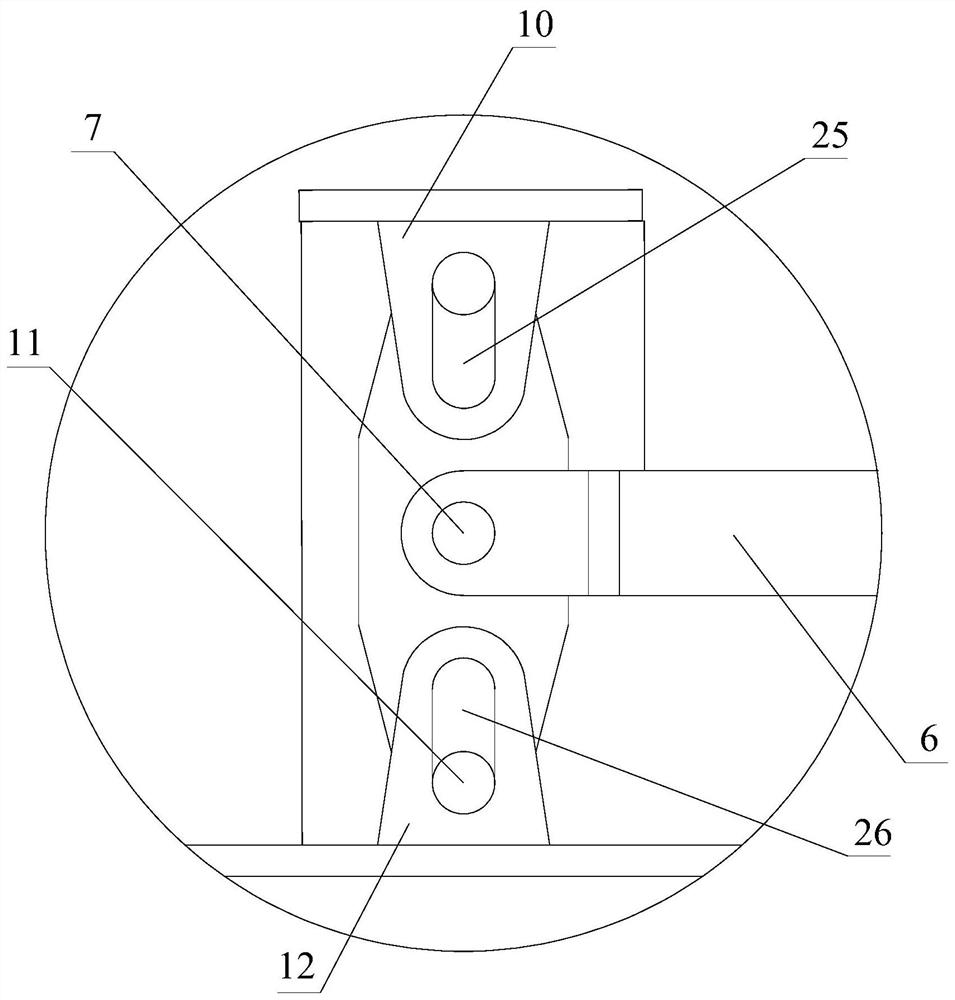

[0064] The rigid support 5 includes two vertically arranged side plates 2, and at least two first supports 10 are arranged at intervals on the upper part of the rigid support 5, and each first support 10 is vertically provided with a first strip shaped hole 25;

[0065] The rack 14 is arranged horizontally, and the back of the rack 14 is connected with a rack stiffening plate 13 on the side away from the teeth, and at least two second supports 12 are arranged at intervals along the length direction of the rack 14 on the rack stiffening plate 13 , each second support 12 is vertically provided with a second strip-shaped hole 26, the position of the second strip-shaped hole 26 corresponds to the position of the first support 10, and the number corresponds one by one;

[0066] The first gear 15 meshes with the rack 14;

[0067] There are at least two lever...

Embodiment 2

[0093] Such as Figure 4 As shown, an eddy current damping wall with a speed amplification combined damping device described in this embodiment includes a superstructure 1 and a lower building structure 24, and also includes a speed amplification combined damping device as described in Embodiment 1 , the superstructure 1 is connected to the connector 6 , and the substructure 24 is connected to the rigid support 5 .

[0094] The lower building structure 24 is generally a floor or beam below the rigid support 5; the superstructure 1 is generally a floor or beam above the connector 6;

[0095] When in use, the lower building structure 24 is connected with the rigid support 5 for supporting the rigid support 5, and connecting the superstructure 1 with the connecting piece 6, so that the connecting piece 6 can connect the superstructure 1 The motion of the rack is converted into the motion of the rack 14 after being accelerated, and then further accelerated by the speed-increasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com