Workpiece carrying device

A technology for handling devices and workpieces, applied in the field of automatic processing devices, can solve the problems of high labor intensity of workers, high production costs, disrupted production order, etc., and achieve the effects of reducing labor intensity, high production efficiency, and ensuring high efficiency and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

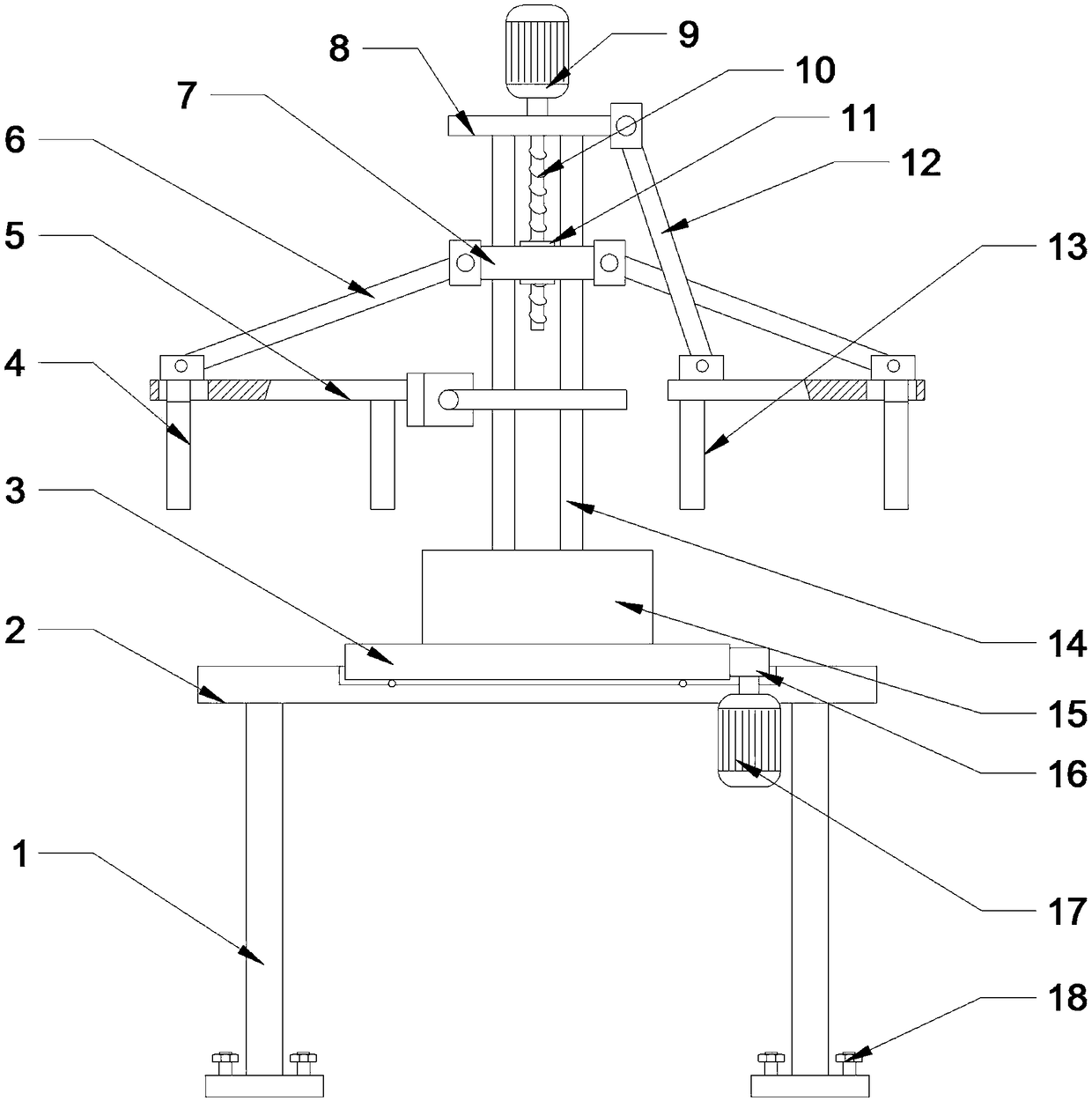

[0024] see figure 1 , a workpiece handling device, comprising a fixed plate 13, including a workbench 2, a rotating seat 15 is installed on the workbench 2, at least two vertical sliding bars 14 are installed on the rotating seat 15, and a positioning platform is installed on the sliding bar 14 8 and the sliding seat 7, the sliding seat 7 is provided with a slide hole through which the slide bar 14 passes, and is sleeved on the slide bar 14 through the slide hole. A connecting rod 6 is provided, and the end of the positioning plate 5 away from the slide bar 14 is provided with a chute. One end of the connecting rod 6 is hinged with the sliding seat 7, and the other end extends into the chute and is hinged with the slide plate 4. The fixed plate 13 is installed in the positioning The plate 5 is close to one end of the slide bar 14 .

[0025] In this example, the sliding seat 7 slides upwards through the cooperation of the slide hole and the slide bar 14, and the pull bar 12 is...

Embodiment 2

[0027] see figure 1 , a workpiece handling device, comprising a fixed plate 13, including a workbench 2, a rotating seat 15 is installed on the workbench 2, at least two vertical sliding bars 14 are installed on the rotating seat 15, and a positioning platform is installed on the sliding bar 14 8 and the sliding seat 7, the sliding seat 7 is provided with a slide hole through which the slide bar 14 passes, and is sleeved on the slide bar 14 through the slide hole. A connecting rod 6 is provided, and the end of the positioning plate 5 away from the slide bar 14 is provided with a chute. One end of the connecting rod 6 is hinged with the sliding seat 7, and the other end extends into the chute and is hinged with the slide plate 4. The fixed plate 13 is installed in the positioning The plate 5 is close to one end of the slide bar 14 .

[0028] There are two positioning platforms 8, and the sliding seat 7 is socketed on the slide bar 14 between the two positioning platforms 8. Th...

Embodiment 3

[0031] see figure 1 , a workpiece handling device, comprising a fixed plate 13, including a workbench 2, a rotating seat 15 is installed on the workbench 2, at least two vertical sliding bars 14 are installed on the rotating seat 15, and a positioning platform is installed on the sliding bar 14 8 and the sliding seat 7, the sliding seat 7 is provided with a slide hole through which the slide bar 14 passes, and is sleeved on the slide bar 14 through the slide hole. A connecting rod 6 is provided, and the end of the positioning plate 5 away from the slide bar 14 is provided with a chute. One end of the connecting rod 6 is hinged with the sliding seat 7, and the other end extends into the chute and is hinged with the slide plate 4. The fixed plate 13 is installed in the positioning The plate 5 is close to one end of the slide bar 14 .

[0032] The workbench 2 is provided with a groove embedded in the ring gear 3, the rotating seat 15 is installed on the ring gear 3, the ring gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com