Hydraulic pipe coiler and construction machinery

A hydraulic hose reel and engineering machinery technology, applied in the field of machinery, can solve the problems of reduced winding space, complex processing and assembly, and complex assembly, and achieve the effects of improving space utilization, increasing winding space, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

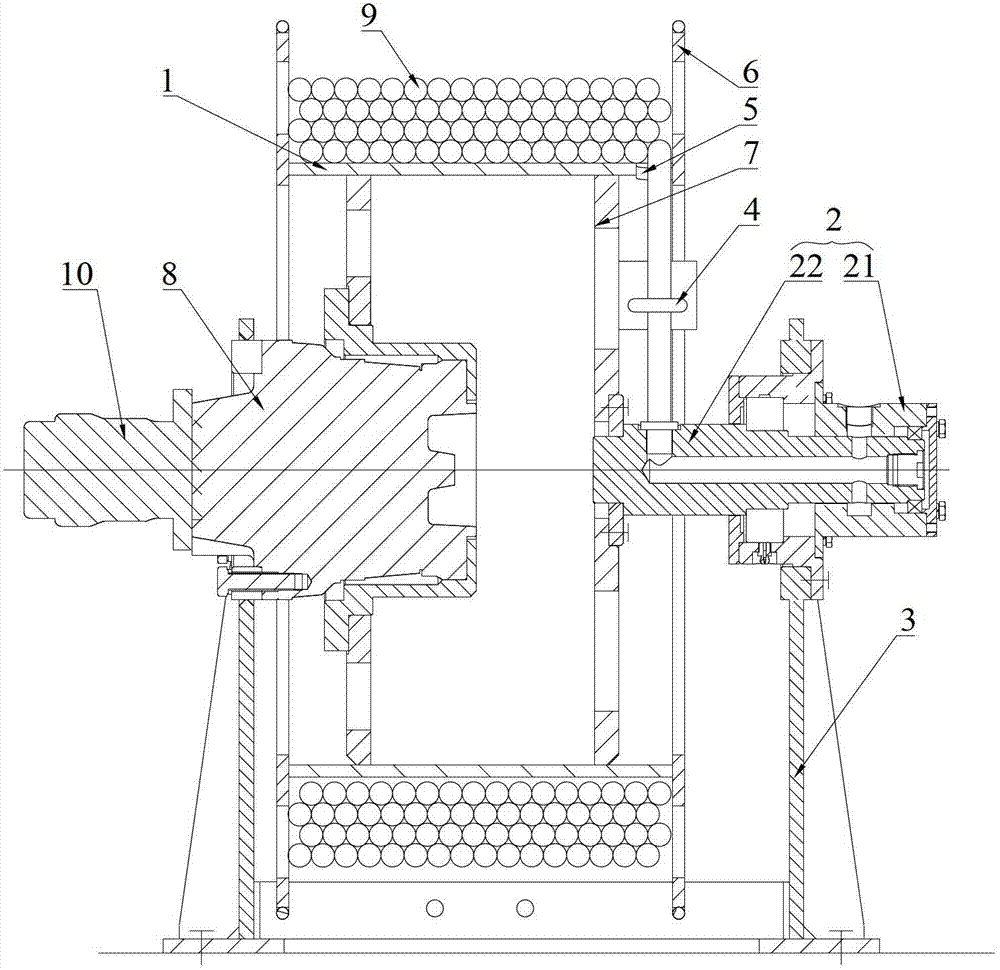

[0028] Such as figure 2 Shown is a hydraulic hose reel provided by an embodiment of the present invention, including a reel 1, a swivel joint 2 and a bracket 3, wherein the swivel joint 2 is arranged coaxially with the reel 1, and includes a jacket 21 and a core 22; There is a liquid inlet on the jacket 21, and the jacket 21 is fixedly arranged on the bracket 3; one end of the core 22 is rotatably nested in the middle of the jacket 21, and the other end is provided with a liquid outlet, and one end of the core 22 is provided with a liquid outlet One side of the reel 1 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap