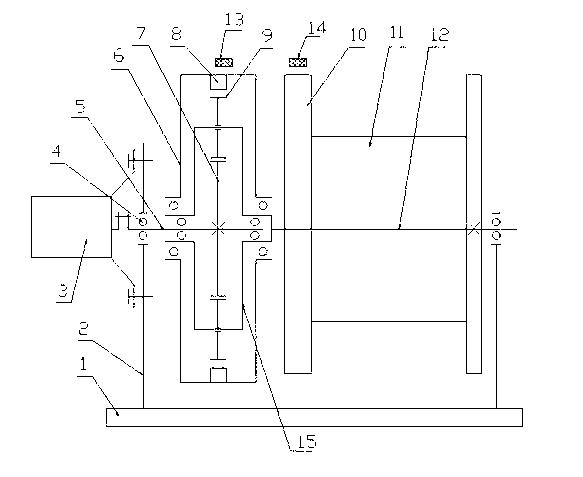

Structure of windlass

A hoist and reel technology, applied in the field of hoist equipment, can solve the problems of large volume, unfavorable installation and use, and small size, and achieve the effect of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the figure, the structure of the winch includes a base 1, a bracket 2, a motor 3, a bearing 4, a drive shaft 5, a retaining ring 6, a central gear 7, an internal gear 8, a planetary gear 9, a brake disc 10, and a reel 11. Transmission shaft 12, working brake 13, stop brake 14, and disc planetary gear carrier 15. The frame components include base 1 and two brackets, and two brackets 2 are fixedly installed on the base 1. The transmission part consists of bearing 4, drive shaft 5, retaining ring 6, sun gear 7, ring gear 8, planetary gear 9, disc planetary gear carrier 15, the retaining ring 6 and disc planetary gear carrier 15 The bearing 4 is fixedly installed on the same drive shaft 5, and they all have the degree of freedom of mutual transmission, and the disc planetary gear carrier 15 is inside the retaining ring 6, and the gear is fixedly installed inside the retaining ring 6 8. Two or three identical planetary gears 9 are evenly distributed on the outer ring of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com