Preparation method of quatenary core end epoxy hyperbranched polyester

A technology of hyperbranched polyester and terminal hydroxyl hyperbranching, applied in the field of composite materials, can solve the problems of single structure of hyperbranched polyester, complex synthesis process, poor compatibility of epoxy resin, etc., and achieve important promotion and application value , The synthesis process is simple, and the effect of accelerating the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

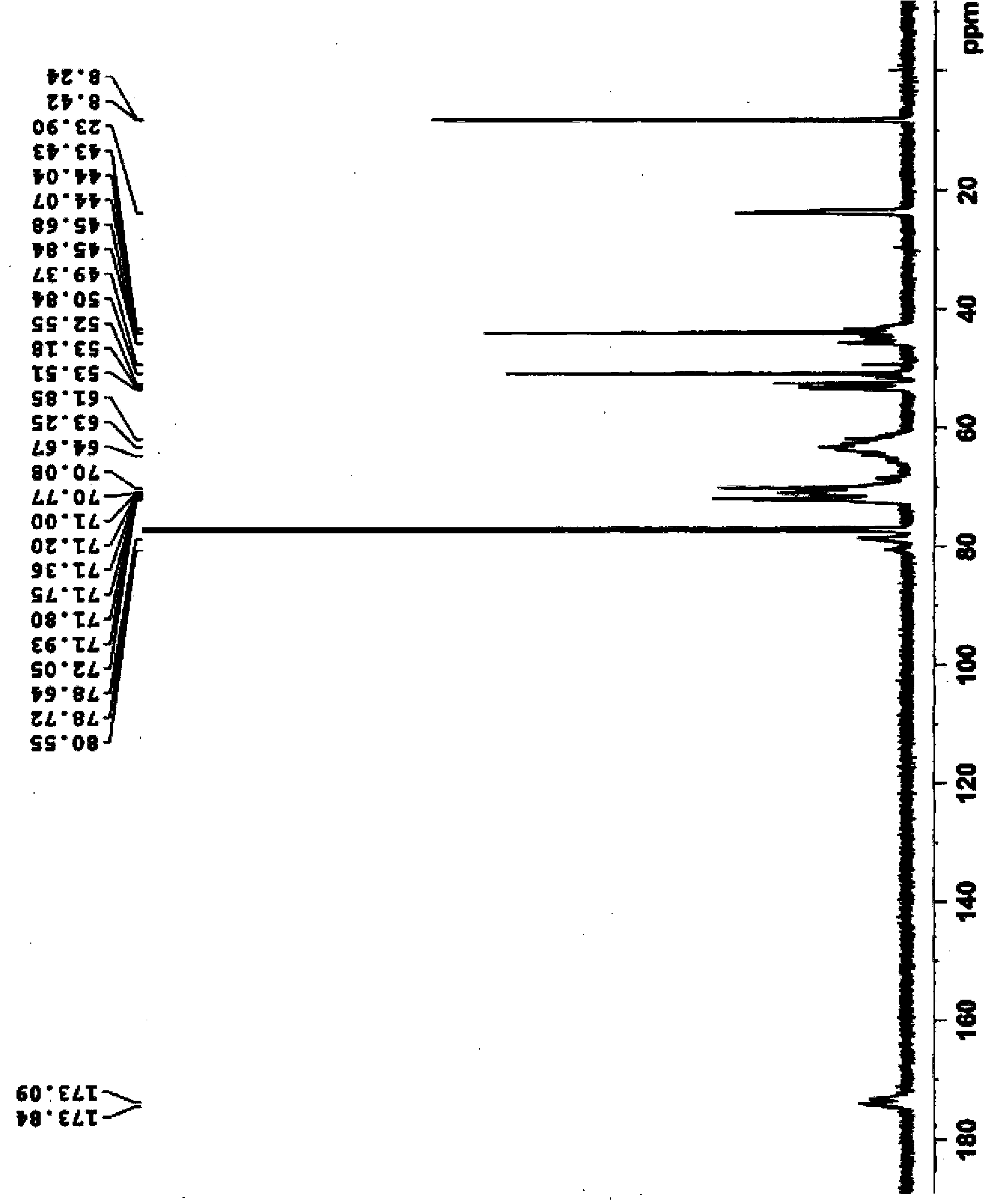

[0017] Specific embodiment one: a kind of quaternary core terminal epoxy hyperbranched polyester of the present embodiment, its structural formula is:

[0018]

[0019] where the R 2 for

[0020]

[0021] AB as stated in 2 for Wherein said n is a positive integer.

[0022] The quaternary core-end epoxy hyperbranched polyester described in this embodiment is centered on a quaternary core polyol, AB 2 The group is a three-dimensional network structure formed by repeating units.

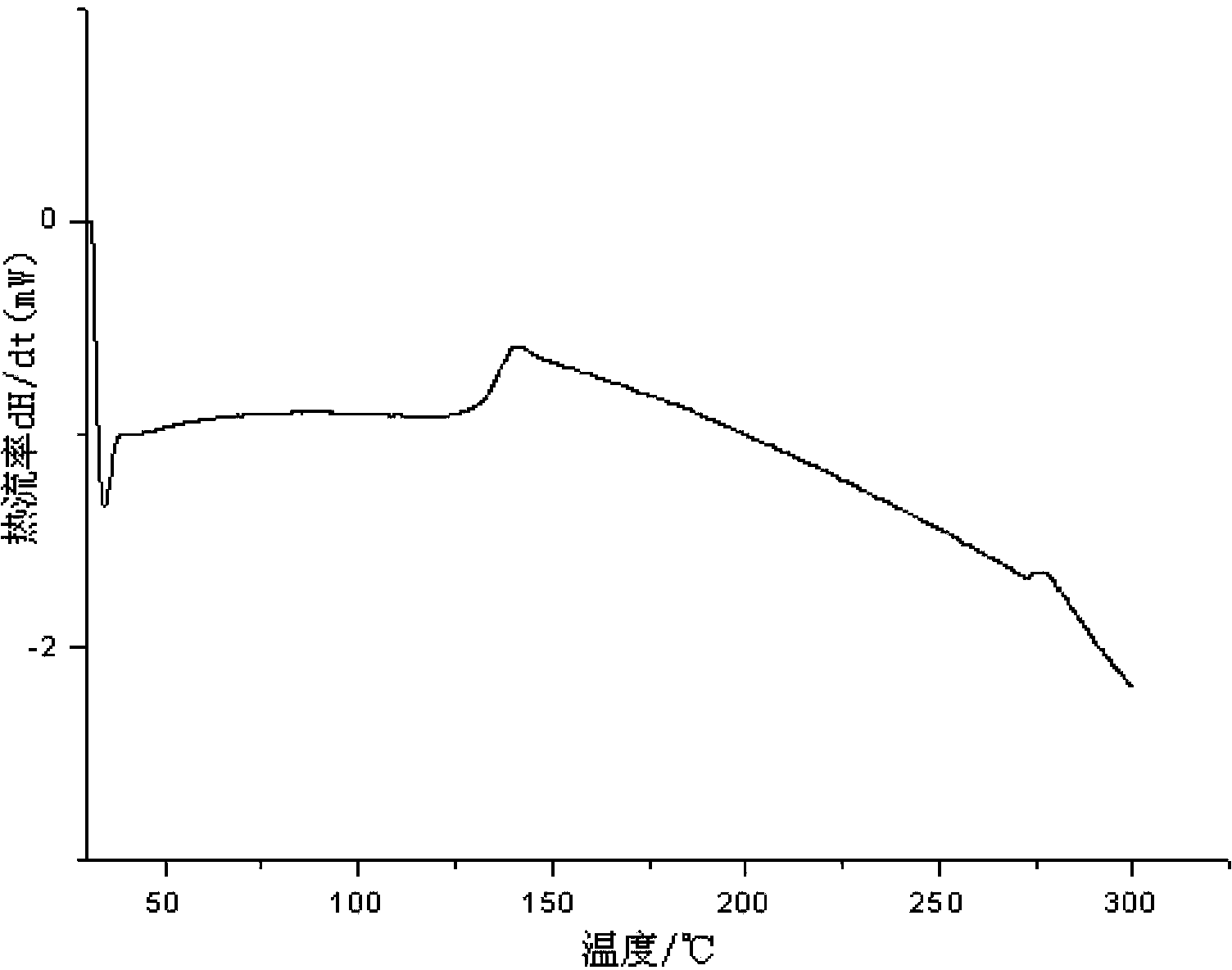

[0023] The spherical three-dimensional structure of the four-membered core-terminated epoxy hyperbranched polyester described in this embodiment can reduce the shrinkage rate of the epoxy cured product.

[0024] The active end groups of the four-membered core-terminated epoxy hyperbranched polyester described in this embodiment can directly participate in the curing reaction to form a three-dimensional network structure, and the numerous terminal functional groups can accelerate the curi...

specific Embodiment approach 2

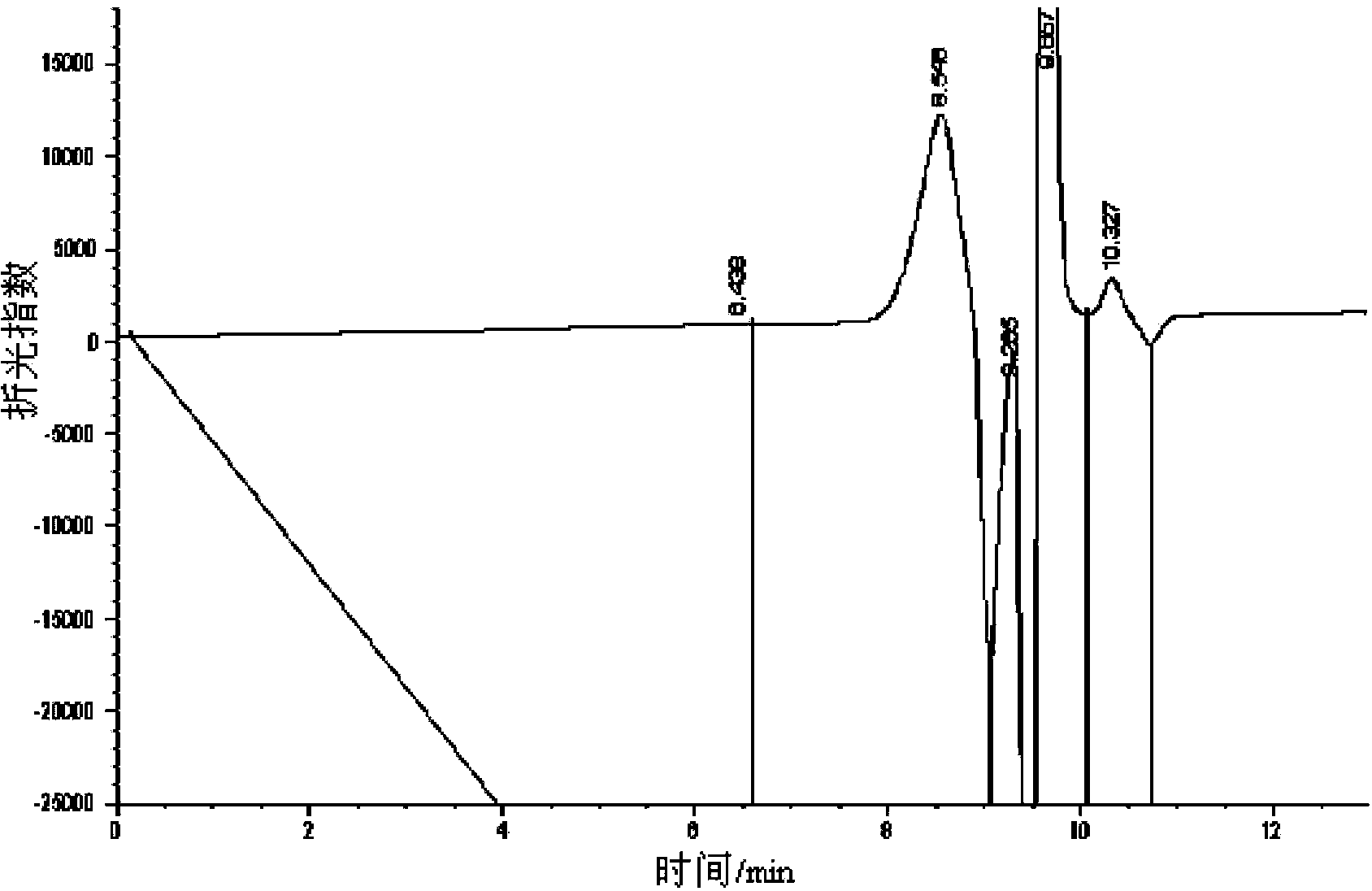

[0026] Specific embodiment two: the preparation method of a kind of quaternary core terminal epoxy group hyperbranched polyester of the present embodiment is specifically completed according to the following steps:

[0027]1. Mixing and stirring: Put the quaternary core polyol and the repeating unit in the flask according to the substance ratio of 1:(1~15), at a temperature of 100°C~240°C, and a stirring speed of 500 rpm~ Stir under the condition of 1500 rpm until completely dissolved to obtain the dissolved mixture; 2. Prepare the crude product of hydroxyl-terminated hyperbranched polyester: add the esterification reaction catalyst to the dissolved mixture obtained in step 1, and the esterification reaction The mass ratio of the catalyst to the dissolved mixture obtained in step 1 is (0.2-3):100, and the temperature is 60°C-200°C and the stirring speed is 500 rpm-1500 rpm. 2h~10h, during the reaction process, vacuum every 30min~1h for 2min~30min, the vacuum degree is -0.095MP...

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the quaternary core polyol described in step one is pentaerythritol, diglycerol, 1,2,4,5-benzenetetraphenol , 1,2,3,5-benzenetetraphenol or ditrimethylolpropane; the repeating unit described in step 1 is dimethylol propionic acid, dimethylol butyric acid, 3,5-dihydroxybenzene Formic acid, 5-hydroxyisophthalic acid, acetylated derivatives of dimethylolpropionic acid, acetylated derivatives of dimethylolbutyric acid, acetylated derivatives of 3,5-dihydroxybenzoic acid, 5- Acetylated derivatives of hydroxyisophthalic acid, silylated derivatives of dimethylolpropionic acid, silylated derivatives of dimethylolbutyric acid, silylated derivatives of 3,5-dihydroxybenzoic acid, 5 - silylated derivatives of hydroxyisophthalic acid or 4,4-bis(4-hydroxyphenyl)pentanoic acid. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com