Pre-filling sand prevention method of highly-deviated well casing pipe and dedicated sand-filter pipe thereof

A technology of highly deviated wells and sand filter pipes, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve the problems of short sand control period of wells and easy damage of steam injection, so as to improve safety and The effect on success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

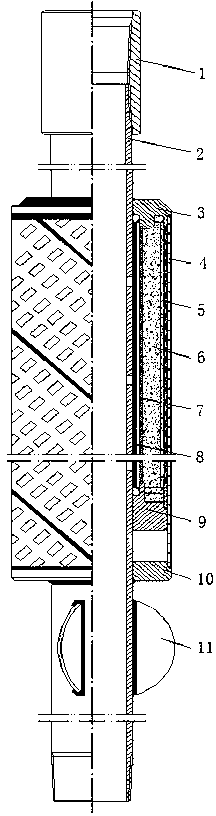

Image

Examples

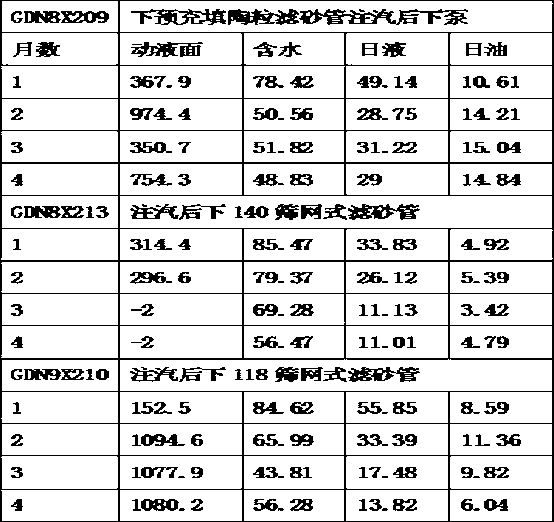

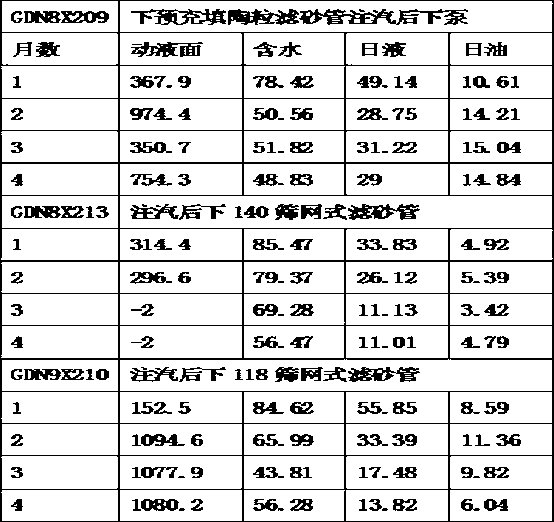

Embodiment 1

[0028] A casing pre-packing sand control method for highly deviated wells, the steps of which are:

[0029] a. Obtain the physical parameters of the oil layer in the production layer, mainly including the median particle size, shale content, and sorting coefficient; for example, if Well GDN8X209 is selected, the formation cement is mainly shale, and the shale content is 11.3%; the median particle size is 0.11mm; The selection factor is 1.7, the sorting is medium, the porosity is 34.2%, and the average air permeability is 1502×10 -3 um 2 , the cementation type is pore contact type; the wettability of the oil layer is strongly hydrophilic.

[0030] b. According to the principle of moderate sand control, determine the sand-retaining accuracy of the sand filter pipe, and then determine the parameters of the pre-filled ceramsite and the parameters of the inner and outer wire-wound screen pipes; 0.4mm. The outer diameter after processing is 146mm.

[0031] c. Treat the wellbore,...

Embodiment 2

[0043] A casing pre-packing sand control method for highly deviated wells, the steps of which are:

[0044] a. Obtain the physical parameters of the oil layer in the production layer, mainly including the median particle size, shale content, and sorting coefficient; for example, if Well GDN8X209 is selected, the formation cement is mainly shale, and the shale content is 11.3%; the median particle size is 0.14mm; The selection factor is 1.7, the sorting is medium, the porosity is 34.2%, and the average air permeability is 1502×10 -3 um 2 , the cementation type is pore contact type; the wettability of the oil layer is strongly hydrophilic.

[0045] b. According to the principle of moderate sand control, determine the sand-retaining accuracy of the sand filter pipe, and then determine the parameters of the pre-filled ceramsite and the parameters of the inner and outer wire-wound screen pipes; 0.8mm. The outer diameter after processing is 142mm.

[0046] c. Treat the wellbore,...

Embodiment 3

[0058] A casing pre-packing sand control method for highly deviated wells, the steps of which are:

[0059] a. Obtain the physical parameters of the oil layer in the production layer, mainly including the median particle size, shale content, and sorting coefficient; for example, if Well GDN8X209 is selected, the formation cement is mainly shale, and the shale content is 11.3%; the median particle size is 0.12mm; The selection factor is 1.7, the sorting is medium, the porosity is 34.2%, and the average air permeability is 1502×10 -3 um 2 , the cementation type is pore contact type; the wettability of the oil layer is strongly hydrophilic.

[0060] b. According to the principle of moderate sand control, determine the sand-retaining accuracy of the sand filter pipe, and then determine the parameters of the pre-filled ceramsite and the parameters of the inner and outer wire-wound screen pipes; 0.6mm. The outer diameter after processing is 144mm.

[0061] c. Treat the wellbore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com