A non-electric explosion type redundant control electric explosion isolation valve

A redundant control and isolation valve technology, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of large power load, metal chip pollution, etc., to improve reliability, realize miniaturization, and improve opening reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

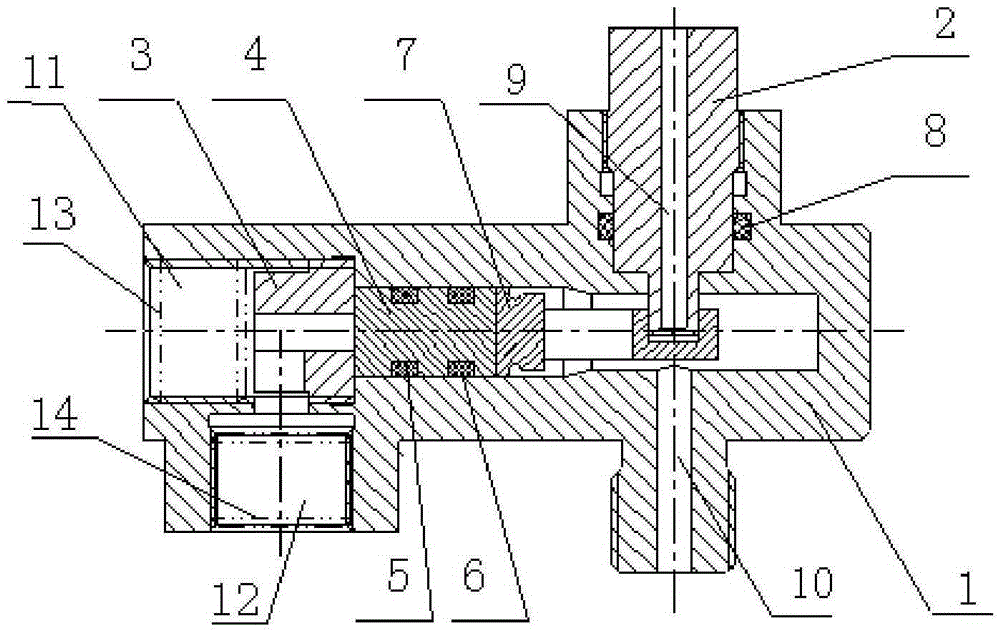

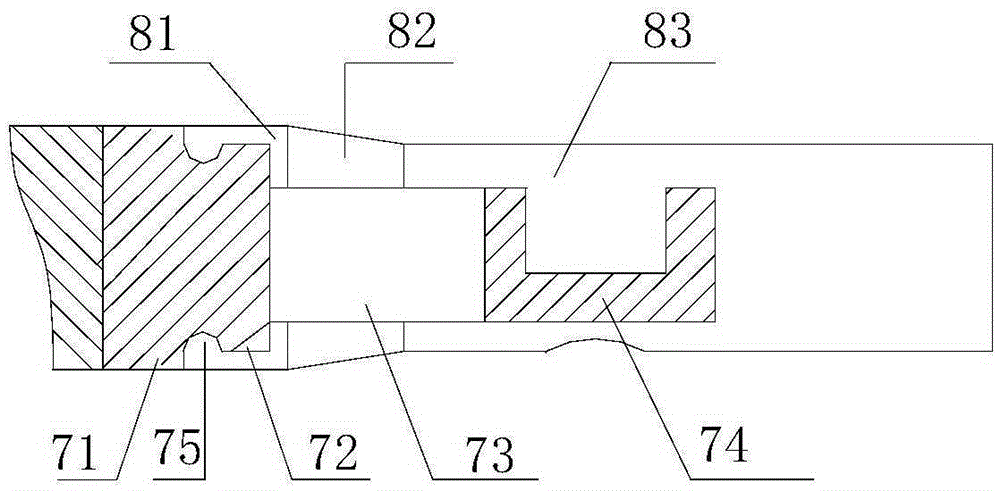

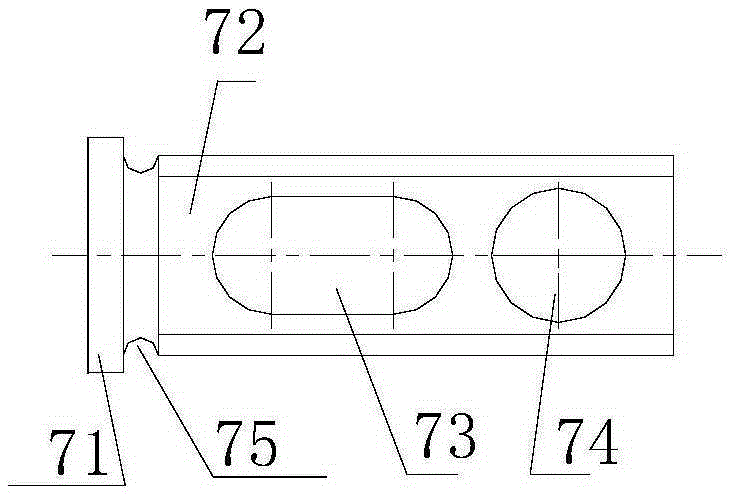

[0025] Such as figure 1 Shown is an embodiment of the present invention, including a valve body 1 and a nozzle 2. The valve body 1 is provided with a first detonation channel 11 in the horizontal direction, and a nozzle 2 and a downstream medium channel 10 in the vertical direction. The nozzle 2 An upstream medium channel 9 is arranged inside, and the upstream medium channel 9 and the downstream medium channel 10 are coaxially arranged and separated by the head of the nozzle. The head of the nozzle extends into the first detonation channel, and the downstream medium channel 10 communicates with the first detonation channel 11 , the first detonating passage 11 is provided with a first detonating device 13, a piston 4 and a cutter 7 in sequence along the axial direction, and also includes a second detonating device 14 and a second detonating passage 12, and the second detonating device is installed in the second detonating passage Inside, the second detonation passage 12 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com