Efficient asymmetric guide blade body matched with annular pumping chamber

A technology of annular pressurized water chamber and guide vane body, which is applied to non-variable pumps, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of blade research and guide vane performance, and achieve improvement Efficiency and operational stability, improved hydraulic matching performance, and reduced flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

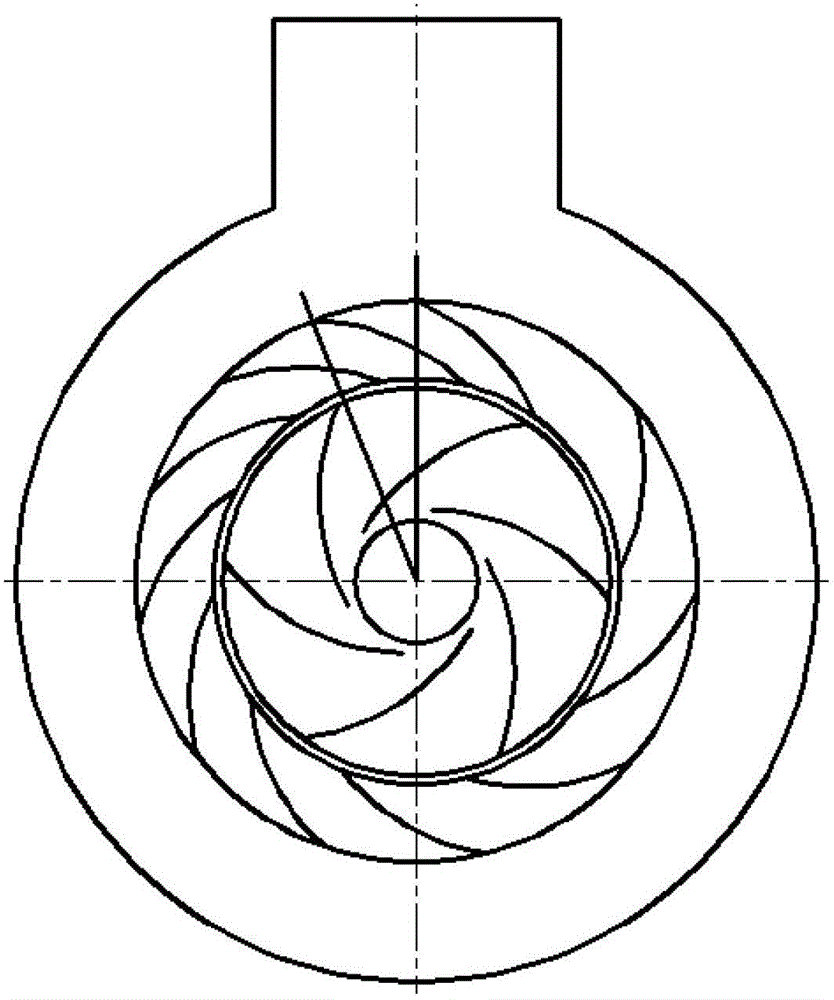

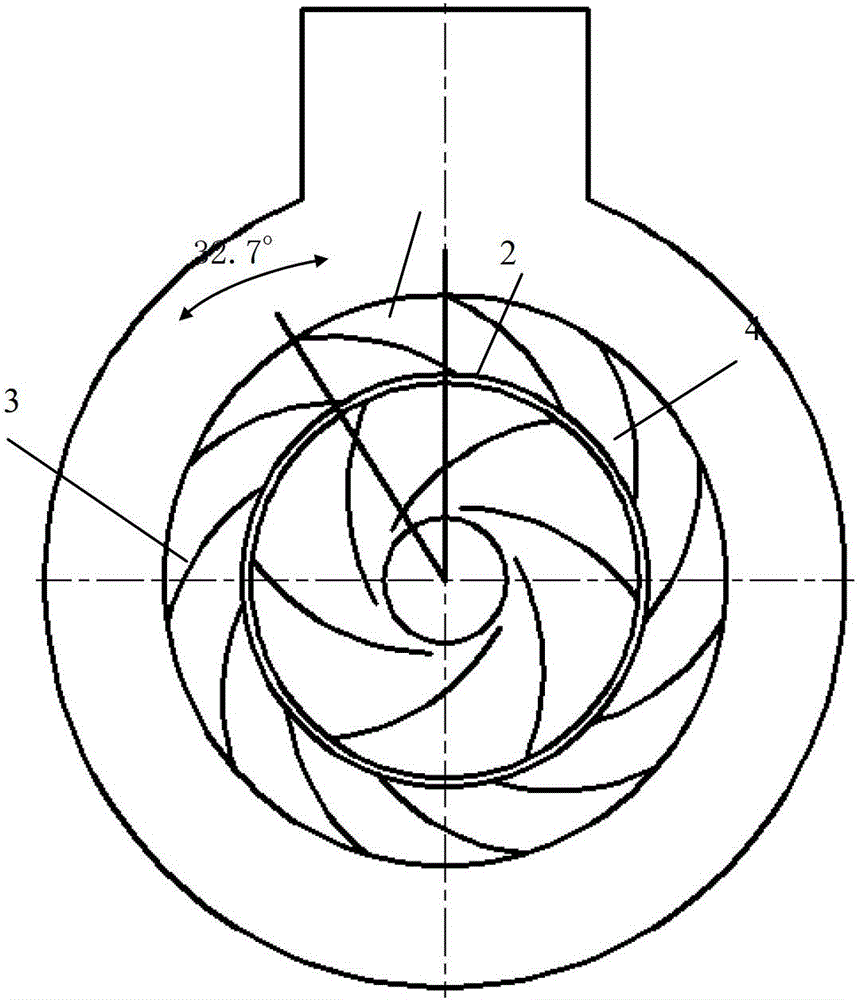

[0010] Such as figure 1 As shown, after the guide vane body is completed according to the traditional design method, the blades are arranged asymmetrically, the blade 1 is fixed on the cover plate 2, and the guide vane body is installed between the impeller 3 and the annular pressure water chamber 4. When designing cylindrical radial guide vanes and twisted space guide vanes, the blades are arranged asymmetrically along the circumference to avoid figure 1 For example: the guide vane has 11 blades, starting from the first blade, the angle θ between the second blade and the first blade is 22.7°, and the angle between the outlet edge of the adjacent blade and the outlet edge of the previous blade is The included angle gradually increases by 2°. The optimal placement angle between the outlet edge of the first blade and the outlet centerline of the annular pressurized water chamber is 15°. The placement angle and wrap angle of all blades are the same. The traditional blade layout i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com