A collection device and reactor for reactor

A collection device and reactor technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve problems such as difficult operation, difficult operation and high cost, mixed catalysts, etc., to achieve improved The effect of filling volume, improving fluid velocity distribution, and uniform fluid velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

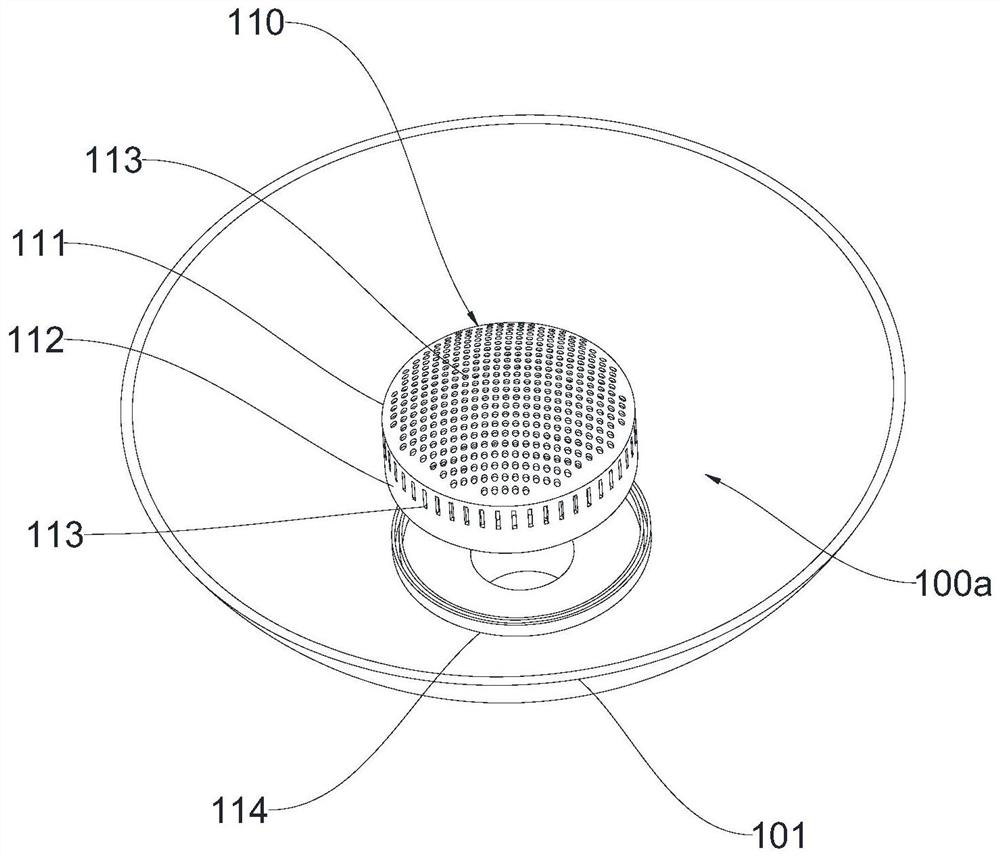

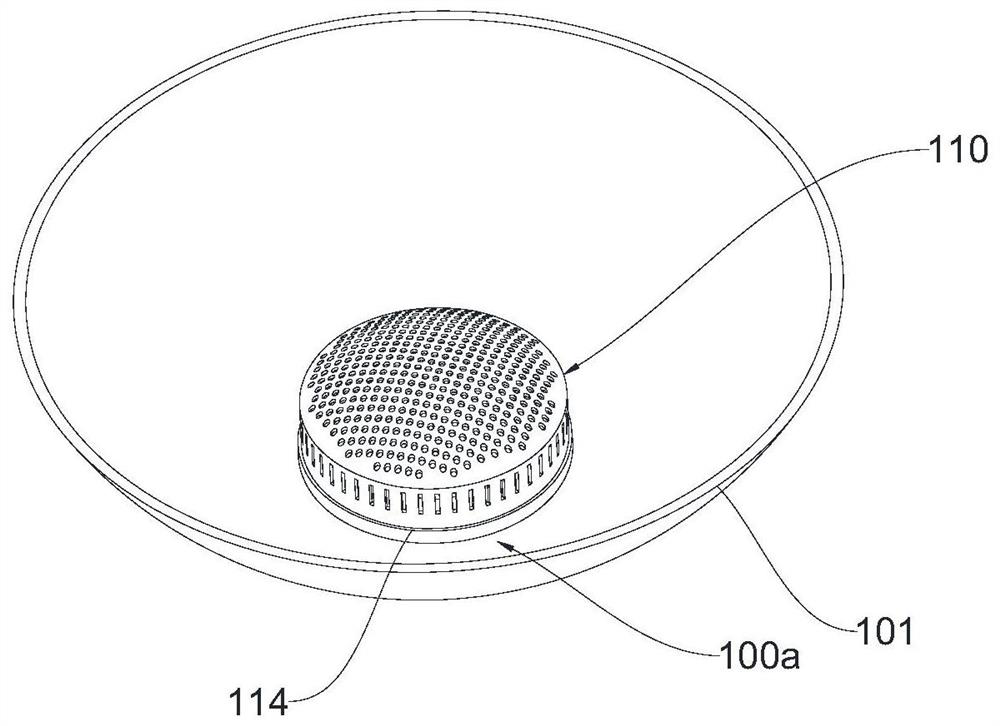

[0038] Please combine Figure 1-Figure 5 The embodiment of the present invention provides a collection device 100a for a reactor, which is installed on the bottom head 101 of the reactor, and is mainly used for isolating the catalyst and allowing the liquid material to pass through the collection device 100a and then output from the bottom outlet of the reactor.

[0039] Specifically, the collection device 100a includes a collection cover 110, the collection cover 110 includes a top end surface 111 and a side end surface 112, the top of the side end surface 112 is connected to the edge of the top end surface 111, and the bottom of the side end surface 112 is connected to the bottom end surface. The inner wall of 101 is connected, and the collection cover 110 is provided with a flow channel for liquid material circulation (as shown in the liquid inlet hole 113); the top end surface 111 of the collection cover 110 is arc-shaped, and the convex surface position of the top end surf...

no. 2 example

[0046] Please refer to Figure 6-Figure 8 , the implementation principle and technical effects of the device provided by the embodiment of the present invention are the same as those of Embodiment 1. For brief description, for the parts not mentioned in this embodiment, reference may be made to the corresponding content in Embodiment 1. The collection device provided in this embodiment can be adapted to larger reactors. Generally speaking, reactors with a diameter greater than 3m can adopt the block combination method provided in this embodiment.

[0047] Specifically, the collection cover 110 is spliced by a plurality of spliced covers 115, and each spliced cover 115 includes a spliced top end face 116 and a spliced side end face 117, and a plurality of spliced top end faces 116 are spliced into a top end face 111. Two splicing side end faces 117 are spliced into the side end face 112 of the collecting cover 110; The method of splicing multiple splicing cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com