Pop-up single-side bolt fastener

A technology for unilateral bolts and fasteners, applied to threaded fasteners, screws, connecting components, etc., can solve problems such as waste of resources, failure to install, weak tensile strength, etc., to increase fastening efficiency, reduce waste, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

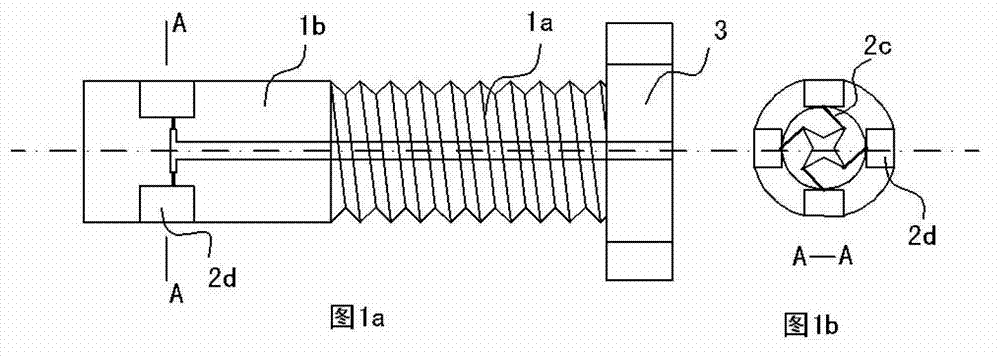

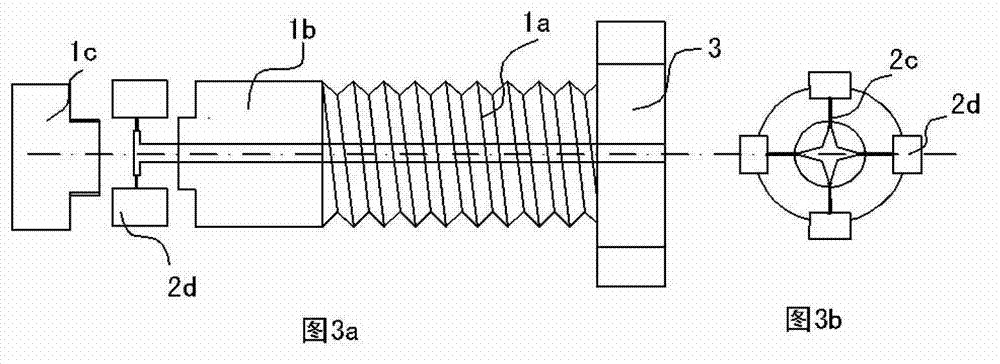

[0026] see Figure 1a with Figure 1b , the structural form of the spring-opening unilateral bolt fastener in this embodiment is:

[0027] Set the tail section of the screw as a threaded rod 1a matched with the nut 3, and the front section of the screw as a cylindrical polished rod 1b; grooves are distributed in the shape of "ten" on the outer circumference of the cylindrical polished rod, except for the grooves The inside of the cylindrical polished rod is the thread used to connect with the end cap 1c; a "T"-shaped cavity is set in the screw rod, the top plane of the "T"-shaped cavity communicates with the groove on the same plane, and the longitudinal shaft hole in the "T"-shaped cavity Starts at the top plane of the "T" shaped cavity and extends through the threaded rod 1a.

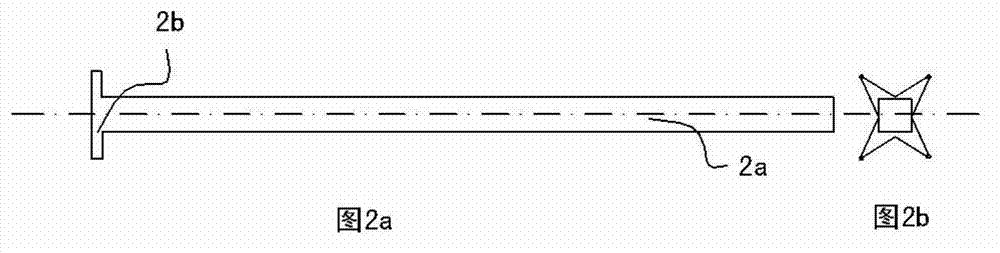

[0028] Such as Figure 2a with Figure 2b As shown, a "T"-shaped rotating part is set in the "T"-shaped cavity, and the top rotating plate 2b of the "T"-shaped rotating part is arranged in a "ten" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com