Analysis meter for residual stress distribution along depth

A technology of depth distribution and residual stress, applied in the direction of measuring force by measuring the change of optical properties of materials when they are stressed, can solve the problems of instability, limit measurement accuracy, inaccuracy, etc., achieve compact instrument, improve beam expansion, etc. area, the effect of improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

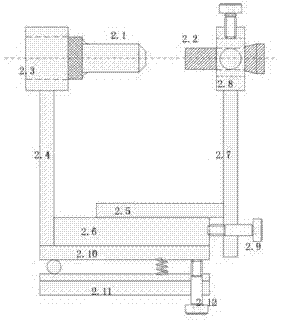

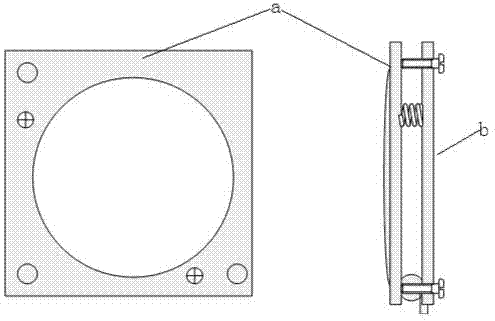

[0023] See attached figure 1 , a residual stress distribution analyzer along depth, which includes: laser 1, spatial filter 2, three-direction moiré instrument body 3, specimen platform 4, phase shifter total reflection part 5, drilling device 6 and image acquisition Device 7 and control processing system 8;

[0024] The laser 1 is fixed on the support frame;

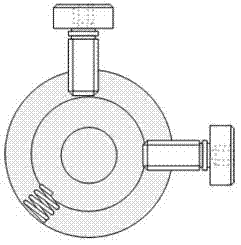

[0025] See attached figure 2 , 3 , the spatial filter 2 includes: high-magnification objective lens 2.1, pinhole 2.2, objective lens adjustment seat 2.3, objective lens adjustment seat support 2.4, sliding plate 2.5, fixed plate 2.6, pinhole adjustment seat support 2.7, pinhole adjustment seat 2.8, stud A2 .9. Leveling plate 2.10, fixing plate 2.11 and stud B2.12; one end of the high-magnification objective lens 2.1 has threads on the periphery, and the high-magnification objective lens 2.1 is screwed into the objective lens adjustment seat 2.3, and the high-magnification objective lens 2.1 can be adjusted according...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap