An automatic locking release and lifting device for power failure retention and its realization method

An automatic locking and electromagnet technology, which is applied in the direction of measuring devices, machine/structural component testing, impact testing, etc., can solve problems such as damaged equipment, inconvenient testing, failure to meet automation requirements, etc., to prevent accidental damage, The structure can be automated and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention are described in detail below.

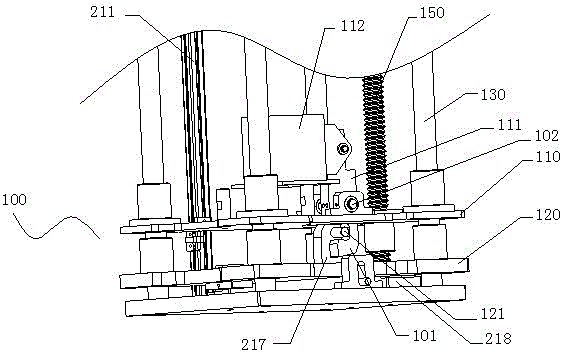

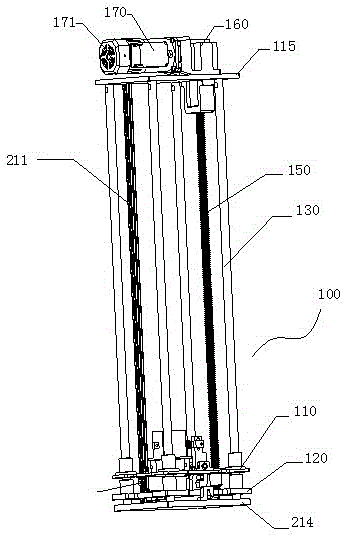

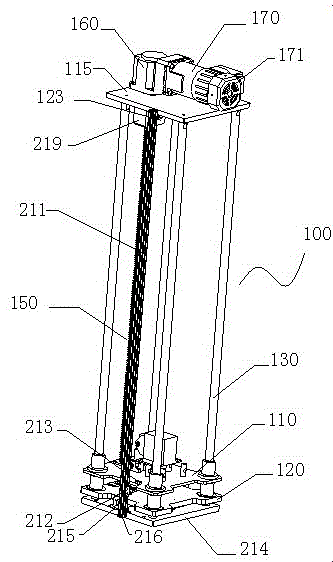

[0033] In the automatic lock release and lifting device and its implementation method provided by the present invention, such as figure 1 with figure 2 As shown, the device configuration includes a base plate 110, which is arranged in parallel with a weight carrier 120, and is arranged in a battery weight impact test device 100 (the figure only shows a part of the structure associated with the device of the present invention) , on the base plate 110, the automatic locking release and lifting device of the present invention is provided for power-off maintenance. The base plate 110 and the heavy object carrier 120 are arranged on several sliding rods 130 in parallel, preferably four sliding rods 130 are arranged so as to guide the falling track of the heavy object carrier 120 .

[0034] Such as figure 1 As shown, in the preferred embodiment of the automatic lock release and lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com