Device and method for measuring heat exchange coefficient of interface in hot stamp process

A technology of interface heat transfer coefficient and hot stamping, applied in the field of hot stamping of high-strength steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

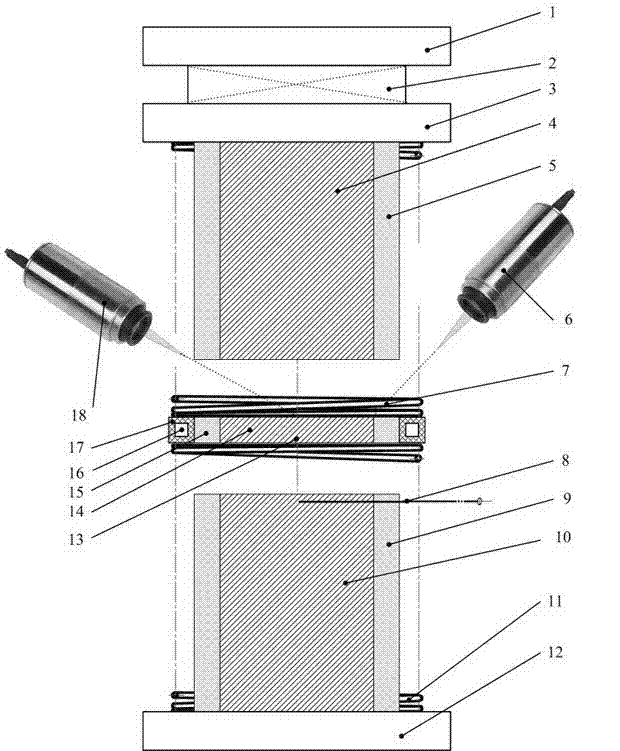

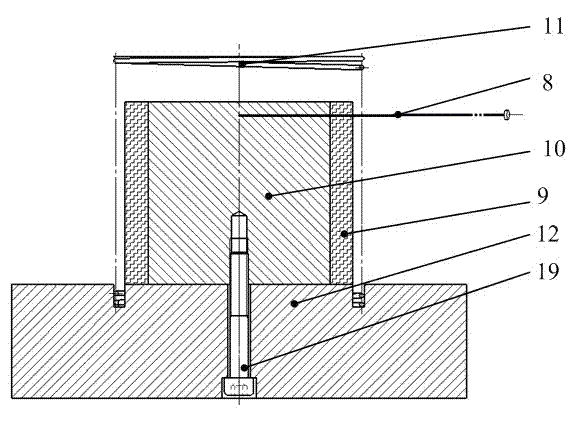

[0082] The present invention will be further described below in conjunction with the accompanying drawings.

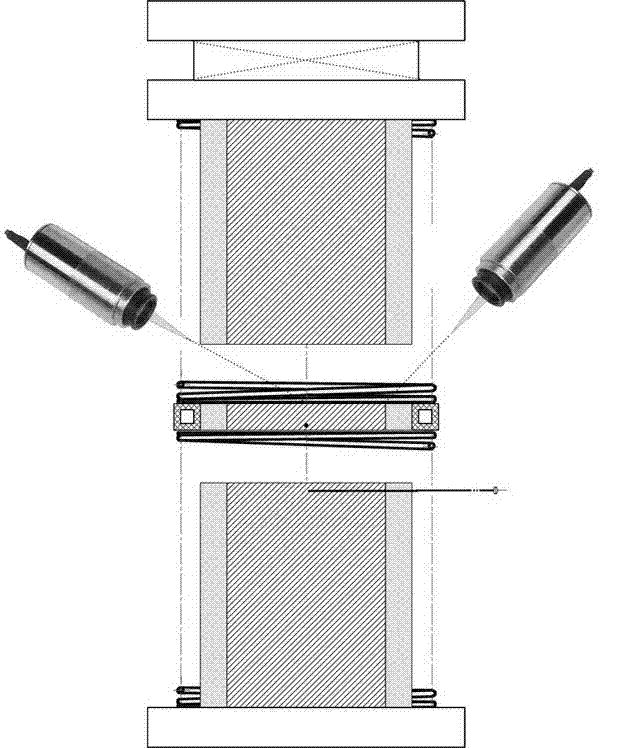

[0083] A device for measuring the interface heat transfer coefficient between a high-temperature steel plate and a die during hot stamping, including a pressure applying device and a measuring device:

[0084] The pressurizing device includes a pressurizing device, an upper workbench and a lower workbench, and the pressurizing device is connected with the upper workbench and the lower workbench respectively; the measuring device includes an upper tooling, a lower tooling and a sample fixing tooling, The upper tooling is fixed on the upper worktable through the upper tooling fixing plate, and the lower tooling is fixed on the lower working table through the lower tooling fixing plate; the sample fixing tooling is arranged between the upper tooling and the lower tooling.

[0085] The upper tooling includes an upper tooling fixing plate 1, an elastic energy storage elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Winding thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com