Performance test jig of motor sub-assembly for copying machine to convey paper

A technology for testing fixtures and copiers, which is applied in the direction of motor generator testing, etc., to achieve the effects of reliable results, convenient and fast testing, and saving testing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

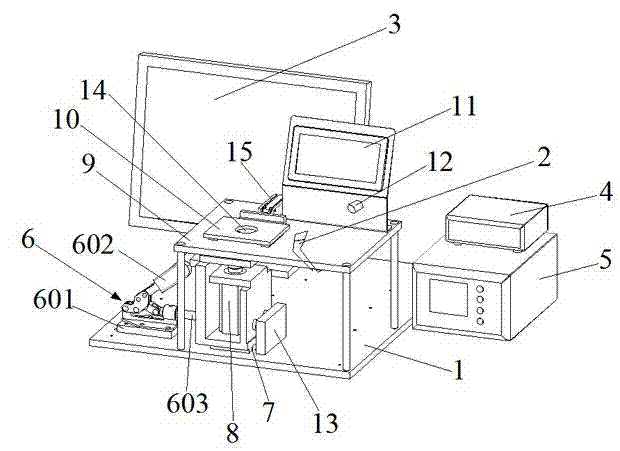

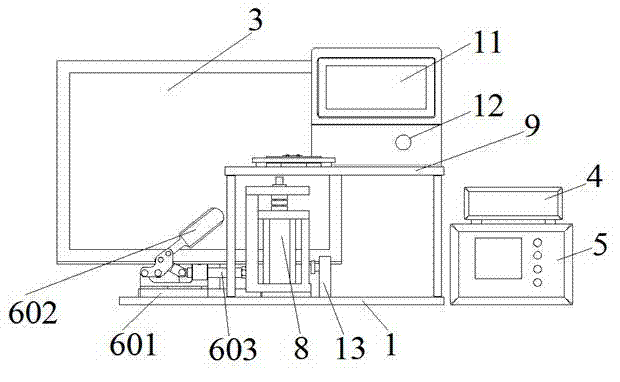

[0015] see figure 1 and figure 2 , The performance detection fixture of the motor assembly for paper conveying of the copier of the present invention includes: a stage 1 , an electrode terminal 2 , a display screen 3 , an F / V converter 4 and a spectrum analyzer 5 . Among them, the carrier 1 is provided with a quick clamp 6 and a slide rail 7, the slide rail 7 is slidably connected to a motor 8 that is displaced with the action of the quick clamp 6, and a fixed table 9 is also installed on the carrier 1, and the fixed table 9 is located in the motor A fixing plate 10 for placing the motor assembly is arranged above the 8 , an operation screen 11 is also installed on the fixing table 9 , and an adjustment knob 12 is arranged beside the operation screen 11 .

[0016] In order to prevent the motor 8 from sliding out of the slide rail 7 , a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com