Horn button detecting device

A detection device and button technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of multiple detection tools and detection personnel, low detection efficiency, increased detection cost, etc., and achieve simple structure, high detection efficiency, The effect of reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described now in conjunction with accompanying drawing.

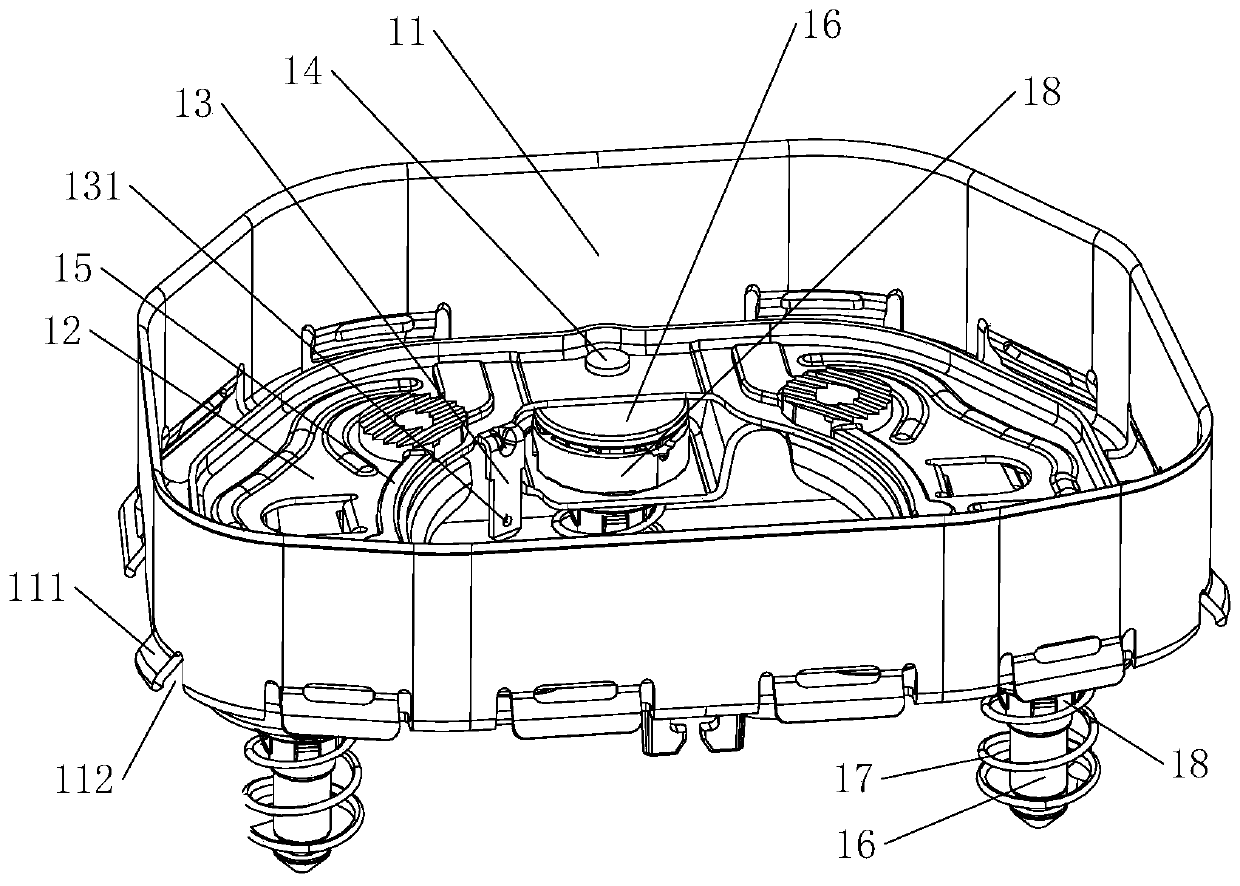

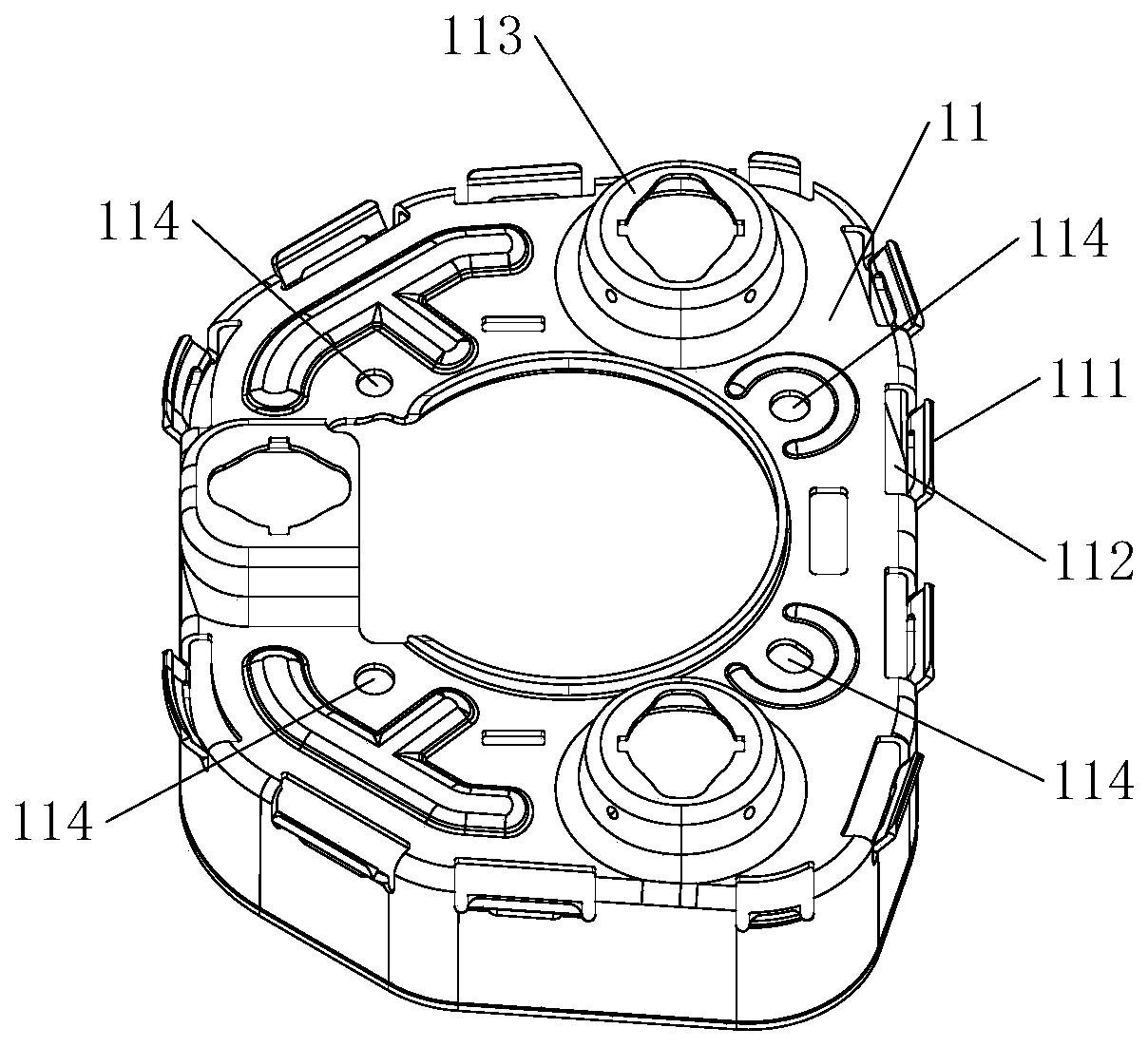

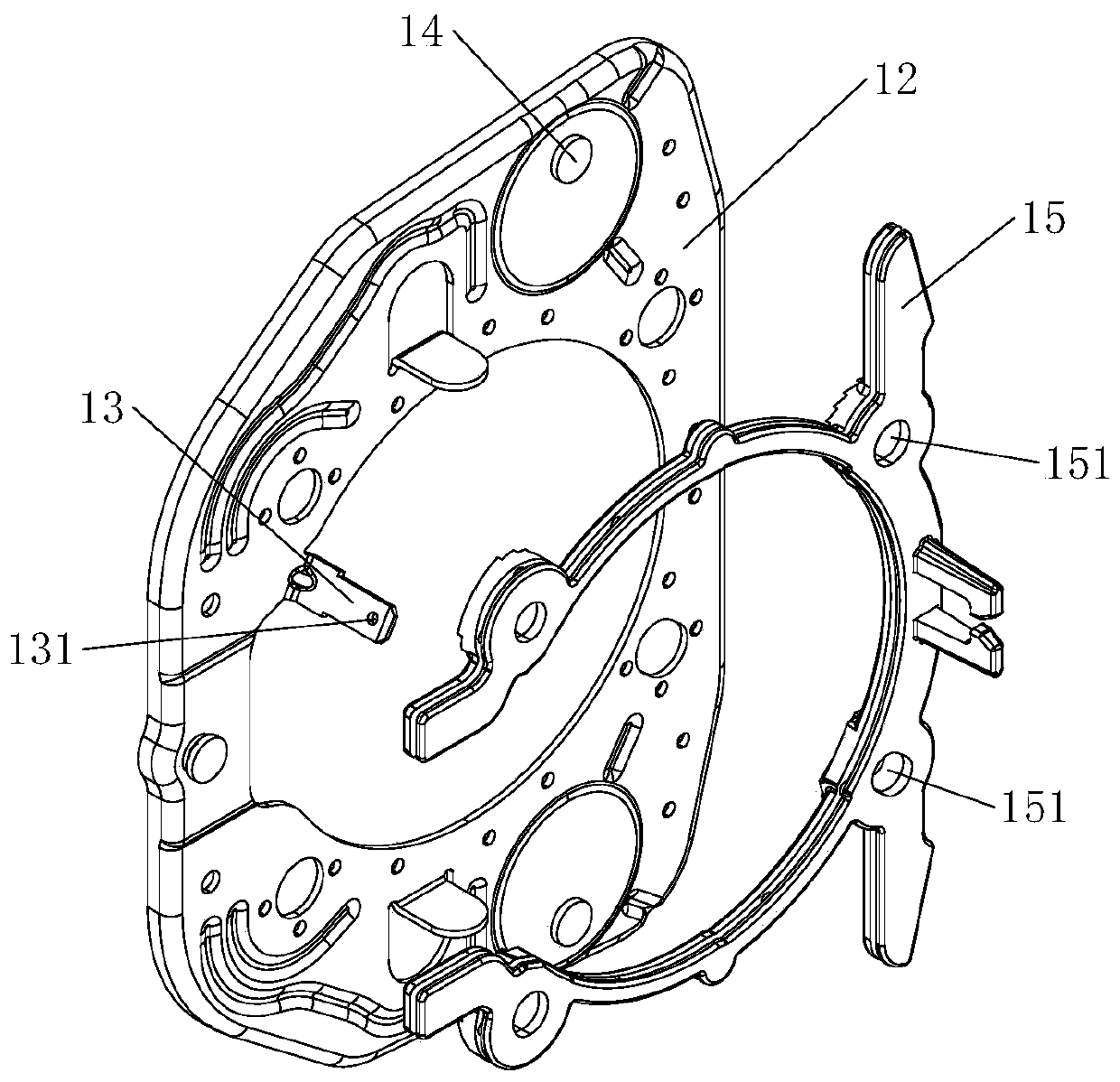

[0032] Such as Figure 1 to Figure 3 As shown, the horn button consists of a button seat 11, a middle plate 12, an insulating plate 15, a rivet 16, a rivet seat 18, a cylindrical spring 17 and a contact 14. The edge of the bottom of the button base 11 is provided with twelve outer bending plates 111 , and the outer bending plates 111 are bent toward the outside of the button base 11 . The bottom of the button seat 11 is provided with four connection holes 114 and a connection seat 113 protruding from the bottom surface. The rivet seat 18 is fixed on the connection seat 113 of the button seat 11, the rivet 16 is movably inserted on the rivet seat 18, the cylindrical spring 17 is fixed on the rivet seat 18, the middle plate 12 and the button seat 11 are both processed by iron or copper plates , the middle plate 12 is provided with a connection plate 13, the connection plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com