Defect detection method, device and system and storage medium

A technology for defect detection and detection results, which is applied in the directions of optical testing flaws/defects, lamp testing, electronic circuit testing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

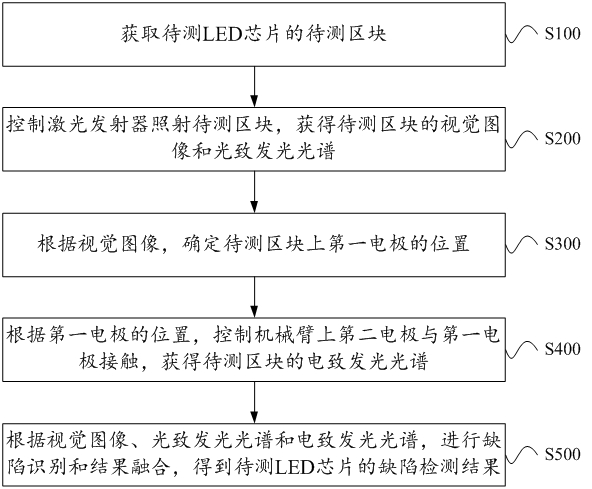

[0075] refer to figure 1 The schematic flowchart of the present invention presents the first embodiment of the defect detection method of the present invention. The defect detection method can be applied to a defect detection system, and specifically can be applied to the defect detection device 10 in the defect detection system.

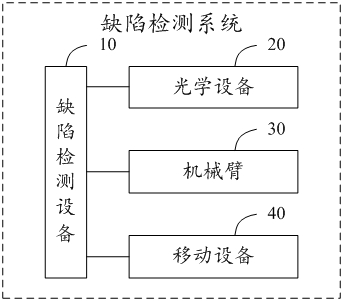

[0076] like figure 2 Shown is a schematic diagram of the structure of the defect detection system. The defect detection system can include:

[0077] an optical device 20 for performing optical processing on the LED chip to be tested, and the optical device 20 includes a laser transmitter;

[0078] The robotic arm 30 is used to move the second electrode to the LED chip to be tested;

[0079] a mobile device 40 for moving the LED chip to be tested; and,

[0080] The defect detection apparatus 10 is used for realizing the defect detection method.

[0081] Those skilled in the art can understand that, figure 2 The hardware structure shown in the ...

Embodiment 2

[0106] Based on the same inventive concept, on the basis of the first embodiment, a second embodiment of the defect detection method of the present invention is further proposed, and the method can also be applied to the defect detection device 10 in the above-mentioned defect detection system.

[0107] The defect detection method of this embodiment will be described in detail below with reference to the accompanying drawings and the above-mentioned defect detection system. The defect detection method may include the following steps:

[0108] Step S100 : acquiring the block to be tested of the LED chip to be tested.

[0109] Further, step S100 may include:

[0110] Step S110 : placing the LED chip to be tested including a plurality of blocks on the mobile device 40 .

[0111] like Figure 4 As shown, the mobile device 40 includes an XYZ stage 4002 and a precision turntable 4001 arranged on the XYZ stage 4002. The LED chip to be tested can be placed on the precision turntable ...

Embodiment 3

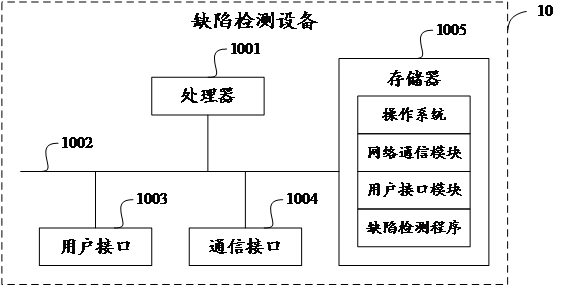

[0179] Based on the same inventive concept, refer to Figure 10 , proposes a first embodiment of the defect detection device of the present invention, which can be a virtual device and is applied to a defect detection system, and is specifically applied to the defect detection device 10 of the above-mentioned defect detection system.

[0180] Combine below Figure 10 The shown schematic diagram of the functional modules describes in detail the defect detection device provided in this embodiment, and the defect detection device may include:

[0181] The block acquisition module is used to acquire the block to be tested of the LED chip to be tested;

[0182] a synchronous acquisition module, used to control the laser transmitter to illuminate the block to be tested to obtain a visual image and photoluminescence spectrum of the block to be tested;

[0183] an electrode positioning module for determining the position of the first electrode on the block to be measured according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com