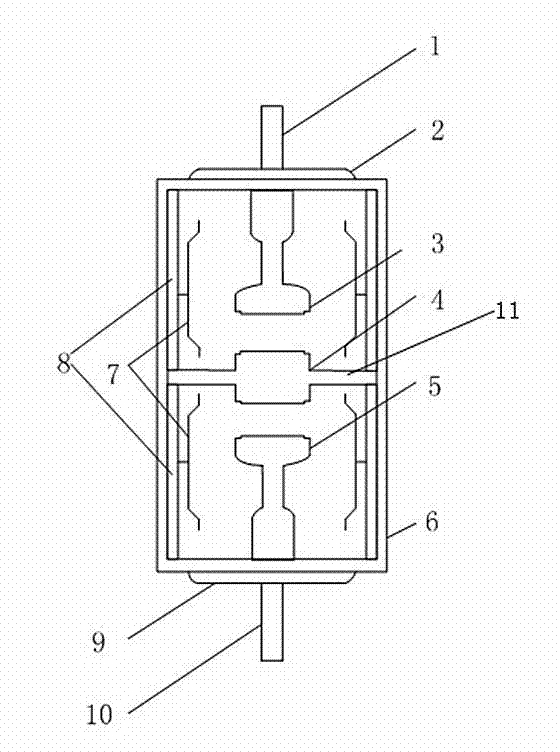

Line-shaped series-connection small-gap dual-fracture vacuum arc-extinguishing chamber

A vacuum interrupter, double-break technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of fracture pressure equalization and complex structure, influence on the reliability of the whole machine, and increase in product cost. The effect of volume reduction, product cost reduction, and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 Shown: a one-line series short-gap double-fracture vacuum interrupter, with an insulating shell 6, an insulating support 8 vertically inside the insulating shell 6, a horizontal partition 11 in the middle of the inner side of the insulating support 8, and a horizontal partition The upper and lower sides of the plate 11 are symmetrically provided with upwardly protruding static contacts 4, and a shielding cover 7 is connected to the inner side of the insulating support (8), and the middle position of the shielding cover 7 of the shielding cover 7 is fixed on the insulating support 8; There is an upper guide sleeve 2 and an upper conductive rod 1 placed in the upper guide sleeve 2 on the upper surface of the shell 6. The lower end of the upper conductive rod 1 has an upper movable contact 3, and the upper movable contact 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com