Silicon wafer automatic feeding and discharging device for plasma enhanced chemical vapor deposition (PECVD) device

A technology for automatic loading and unloading of silicon wafers, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency of manual operation, production cost of silicon wafer crushing, high labor intensity, etc., to avoid high silicon wafer breakage rate , Reduce the labor intensity of workers and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

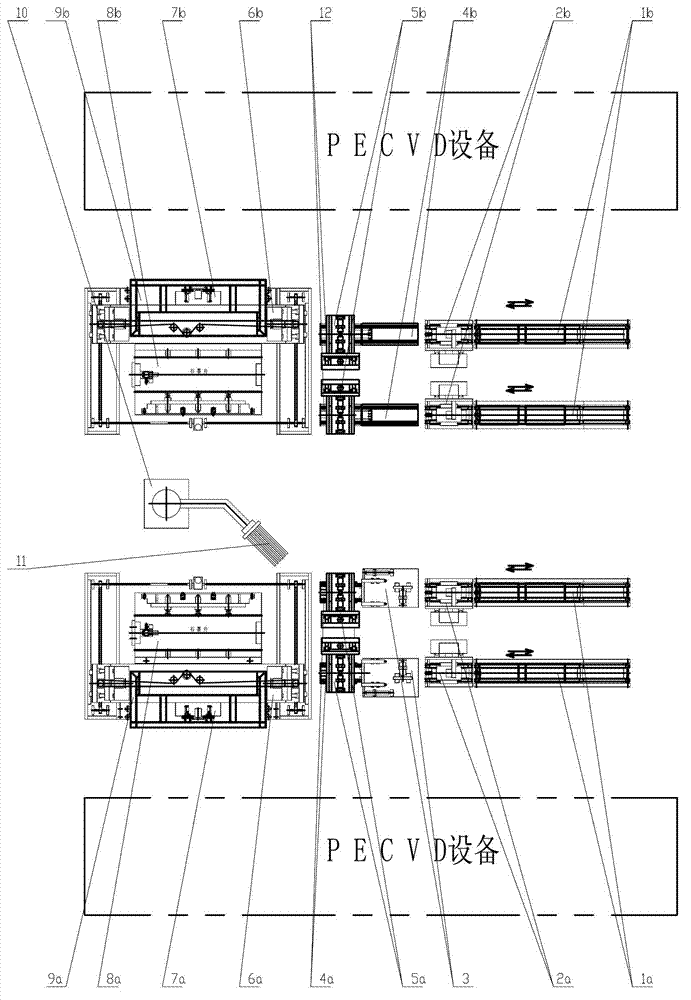

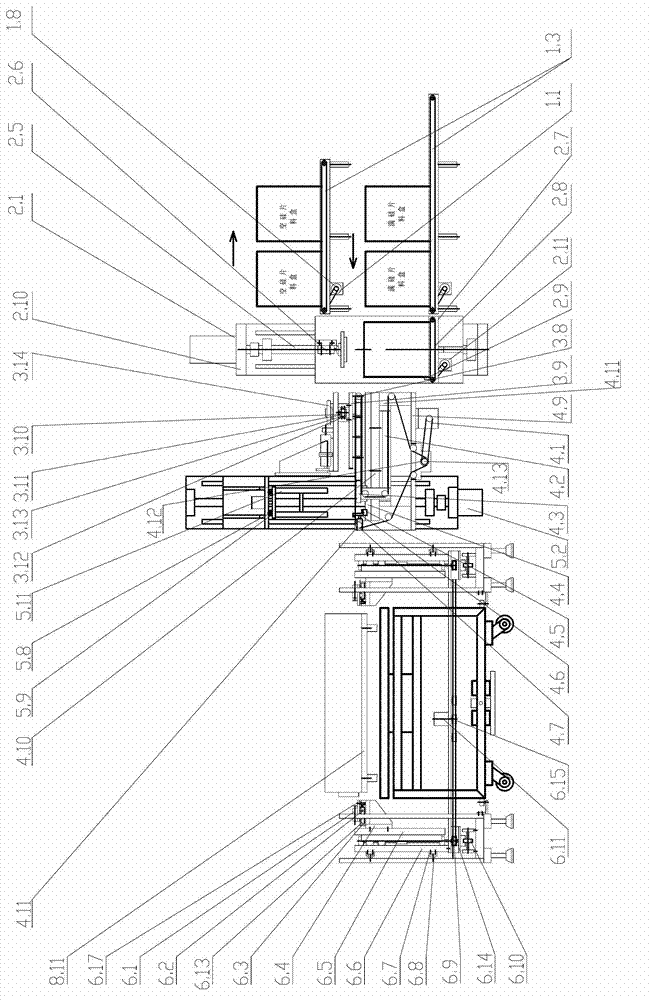

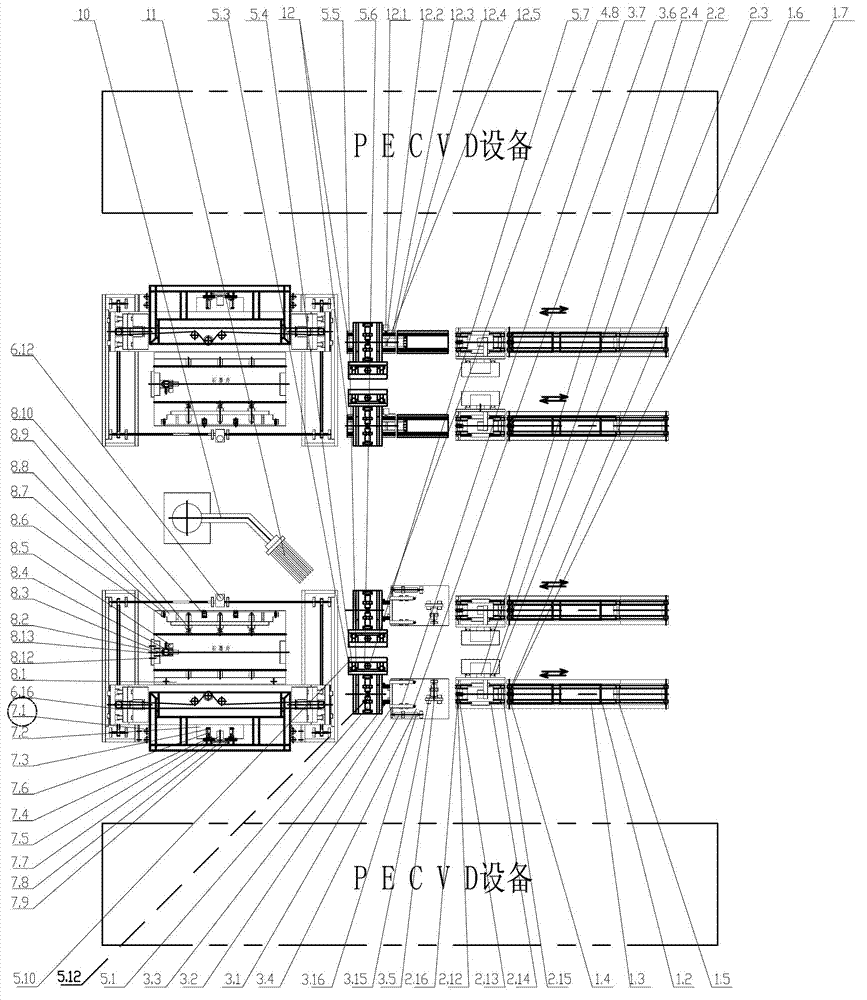

[0031] As shown in the figure, the silicon wafer automatic loading and unloading device for PECVD equipment is equipped with a manipulator 10 rotating on the frame, a suction cup 11 is installed on the manipulator 10, and a first silicon wafer is installed on the frame outside the manipulator 10. Cassette conveying mechanism 1a, first lifting platform mechanism 2a, guiding mechanism 3, first film delivery mechanism 4a, first storage mechanism 5a, first transportation mechanism 6a, first trolley positioning mechanism 7a, first graphite boat positioning Mechanism 8a and the first conveying trolley 9a are equipped with the second silicon wafer cassette conveying mechanism 1b, the second elevating platform mechanism 2b, the sheet conveying mechanism 12, the second sheet discharging conveying mechanism 4b, the second storage material mechanism 5b, the second transport mechanism 6b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com