Coating composition for metal conductors

A composition and coating technology, applied in the direction of metal oxides, cement coatings, coatings, etc., can solve the problems of different heat resistance and mechanical resistance of coatings, achieve the effect of improving storage stability and highlighting heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

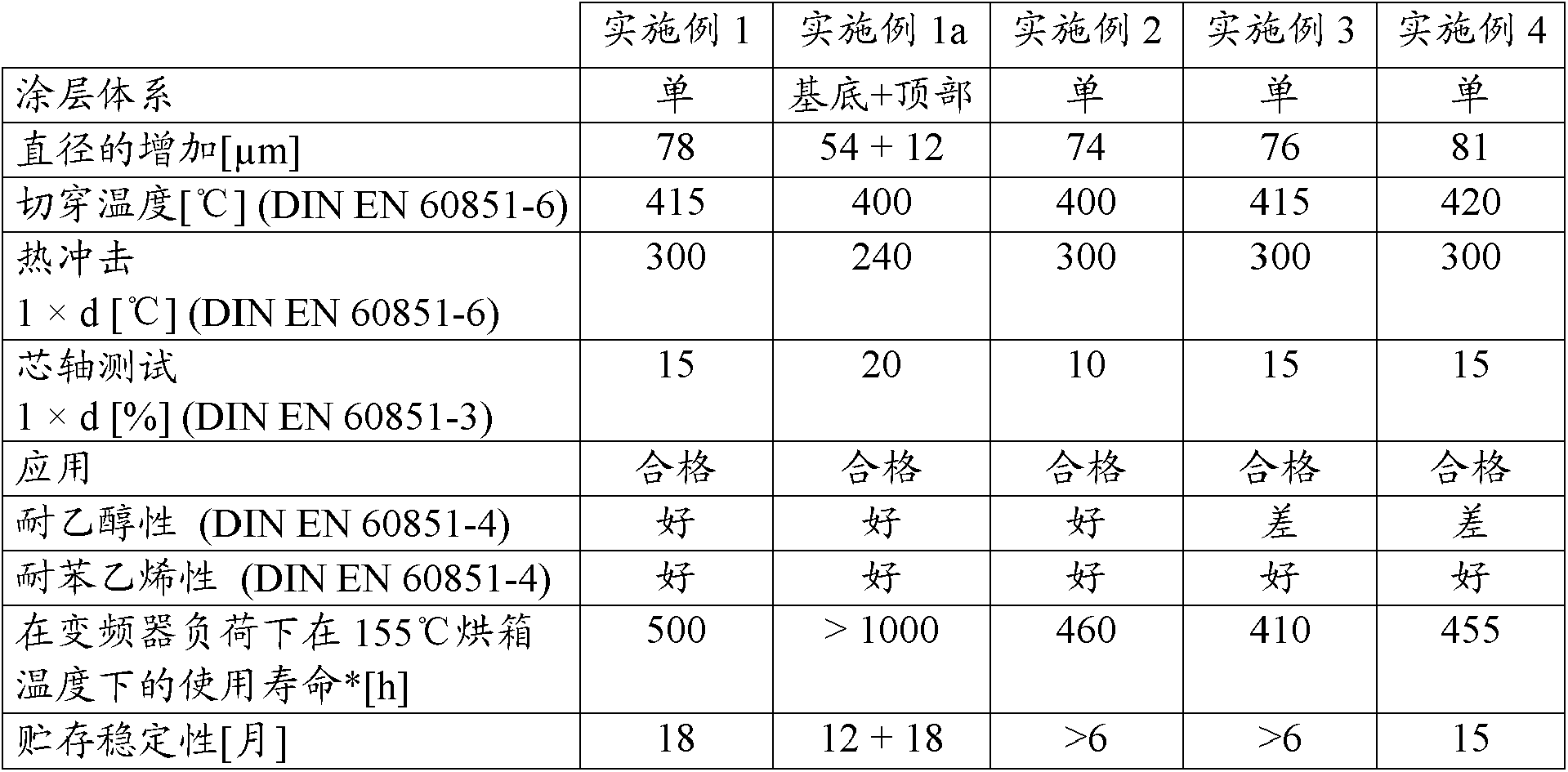

Embodiment 1

[0072] Add 23 parts by weight of anhydrous colloidal silica solution (50 nm), 20 parts by weight of 1,3-dioxo-2-benzofuran-5- Formic acid, 26 parts by weight of 4,4'-methylene diphenyl diisocyanate and 0.2 parts by weight of metal ester catalyst. The mixture was gradually heated to 150°C until carbon dioxide formation was complete. The material was then treated with 1-methyl-2-pyrrolidone, xylene and Thin by 100 to obtain a clear coat. The wire coating has a solids content of 33.0% (1 g, 1 h, 180° C.; DIN EN ISO 3251 ) and a viscosity of 760 mPas (25° C.; DIN 53015 ).

Embodiment 2

[0074] Add 31 parts by weight of titanium dioxide solution (50nm), 20 parts by weight of 1,3-dioxo-2-benzofuran-5-carboxylic acid, 26 parts by weight of 4,4'-methylene diphenyl diisocyanate and 0.2 parts by weight of metal ester catalyst. The mixture was gradually heated to 150°C until carbon dioxide formation was complete. The material was treated with 1-methyl-2-pyrrolidone, xylene and Thin by 100 to obtain a clear coat. The wire coating has a solids content of 33.8% (1 g, 1 h, 180° C.; DIN EN ISO 3251 ) and a viscosity of 840 mPas (25° C.; DIN 53015 ).

Embodiment 3

[0076] Add 37 parts by weight of fused alumina solution (80 nm), 20 parts by weight of 1,3-dioxo-2-benzofuran-5-carboxylic acid, 26 parts by weight into a 2-liter three-necked flask with a stirrer and a thermometer. parts of 4,4'-methylene diphenyl diisocyanate and 0.2 parts by weight of metal ester catalyst. The mixture was gradually heated to 150°C until carbon dioxide formation was complete. The material was treated with 1-methyl-2-pyrrolidone, xylene and Thin by 100 to obtain a clear coat. The wire coating has a solids content of 32.9% (1 g, 1 h, 180° C.; DIN EN ISO 3251 ) and a viscosity of 630 mPas (25° C.; DIN 53015 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com