Connectors with braces and temporary set-up scaffolding

A technology of connectors and diagonal braces, applied in the field of temporary scaffolding, which can solve the problems of costly work, difficult fastening and combining operations, and difficulty in reaching the operator's hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

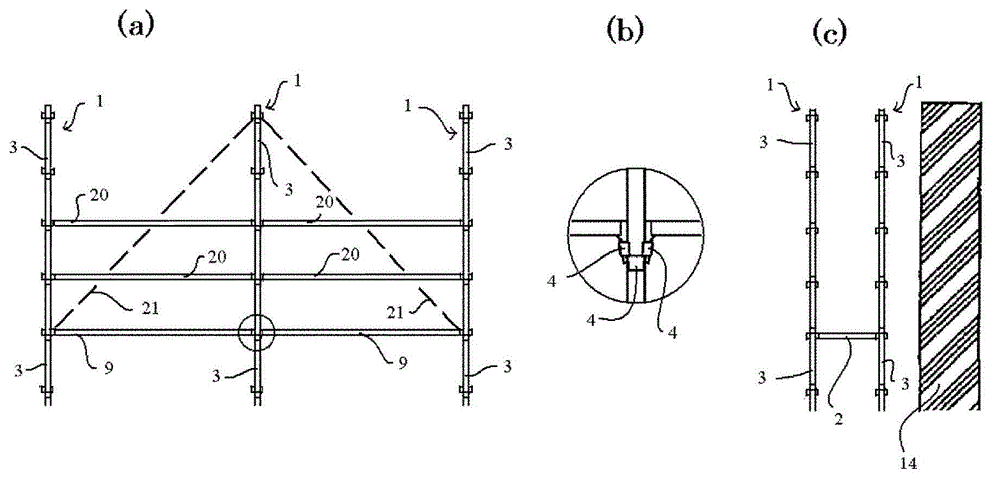

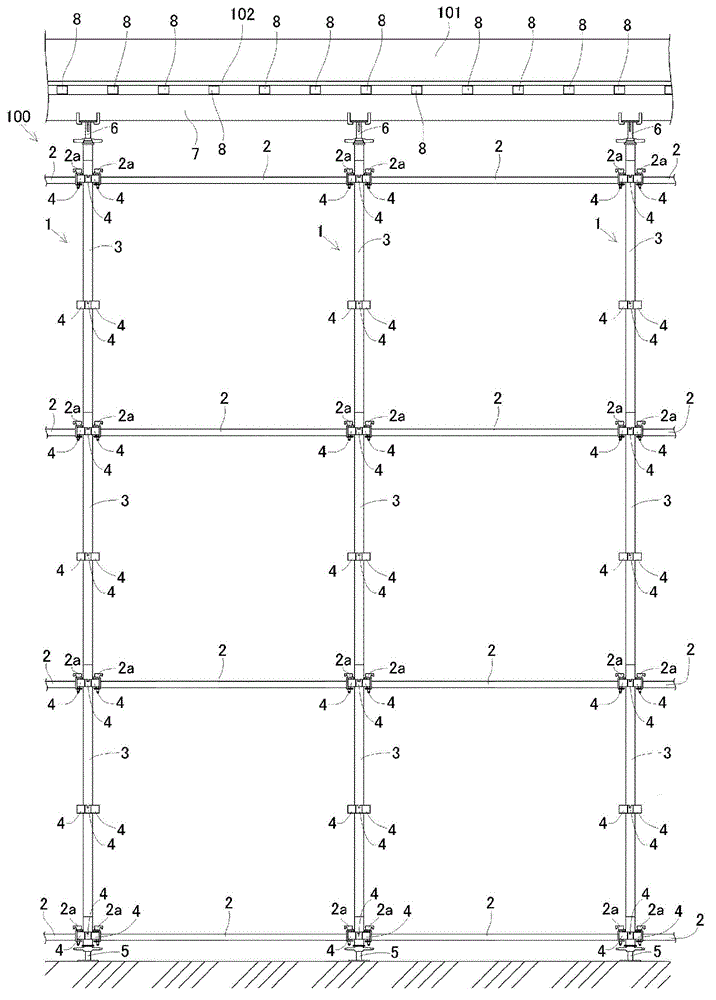

[0086] Figure 10 It is an example of the connector with braces of the present invention. Figure 10 (a) is the front view. Figure 10 (b)~ Figure 10 (d) is an enlarged view of part A, where, Figure 10 (b) represents the left side view, Figure 10 (c) represents the front view, Figure 10 (d) shows a bottom view.

[0087]The braced connector 30 includes a horizontal member 31 made of a pipe made of steel, aluminum, or the like, and two braces 32 that support the horizontal member 31 from obliquely below. The ends of the horizontal members 31 are respectively joined with end plates 40 having notches 40a opening downwards by welding etc. The end portion of the horizontal member 31 can be connected to the pillar member by being hooked to the pillar member. On the other hand, a wedge metal fitting (Japanese: クサビ fitting) 30b is provided at the lower end of the brace 32 by welding or the like, and the wedge metal fitting 30b is hooked to a stopper ( Japanese: コマ) and othe...

Embodiment 2

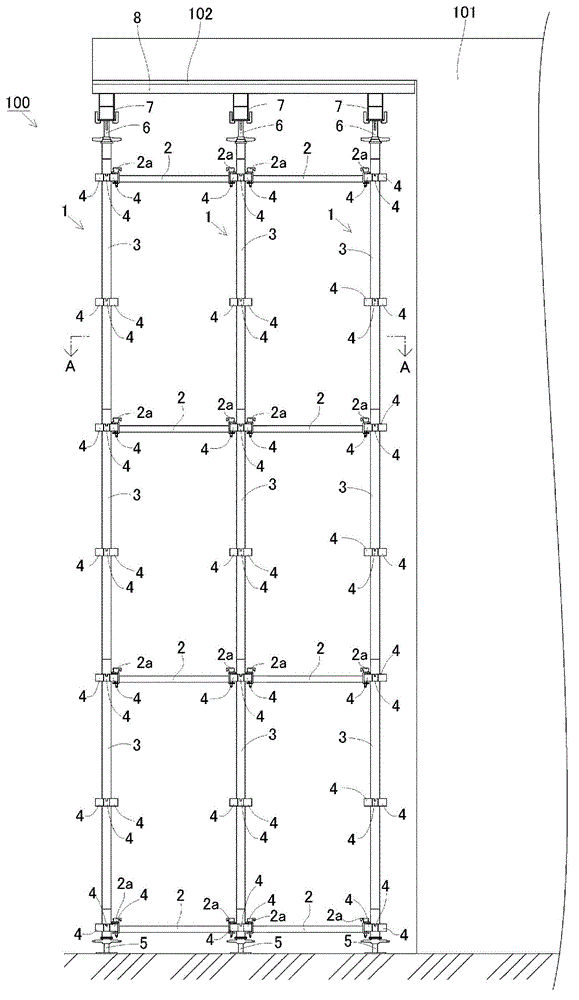

[0108] Figure 18 is another example of the connecting piece with braces of the present invention. Figure 18 (a) is the front view. Figure 18 (b)~ Figure 18 (d) is an enlarged view of part A, where, Figure 18 (b) represents the left side view, Figure 18 (c) represents the front view, Figure 18 (d) shows a bottom view. in addition, Figure 19 It shows the state (front view) after connecting this connector with a brace to the side surface of the pillar member 3. FIG.

[0109] This long braced connector 30 differs from the braced connector of Embodiment 1 only in that the horizontal member 31 is longer. Therefore, similar to the short braced connector shown in Example 1, as the braced connector connected between the pillar members, even if not four places are fastened with wedges, even if the horizontal member Instead of being fastened and joined by wedges, the two ends of the two ends are hooked to the pillar members, and the connector with braces can also be firml...

Embodiment 3

[0111] Figure 20 is another example of the connecting piece with braces of the present invention. Figure 20 (a) is the front view. Figure 20 (b) is an enlarged left side view of part A, Figure 20 (c) is an enlarged front view of part A.

[0112] The braced connector 30 includes a horizontal member 31 made of a pipe made of steel, aluminum, or the like, and two braces 32 that support the horizontal member 31 from obliquely below. Button pins 41 are joined to ends of the horizontal member 31 via end plates 40 , and the ends of the horizontal member 31 can be connected to the pillar members by hooking the ends of the horizontal member 31 to the pillar members. On the other hand, a wedge metal fitting 30b is provided at the lower end of the brace 32 by welding or the like, and the wedge metal fitting 30b is hooked to a connecting metal fitting such as a stopper provided on the side surface of the pillar member and then driven into it. The wedge 30a can securely couple the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com