Suction filtration device and filtering method thereof

A suction filter device and suction filter technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of difficult filtration, crystal precipitation, etc., and achieve the effect of easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

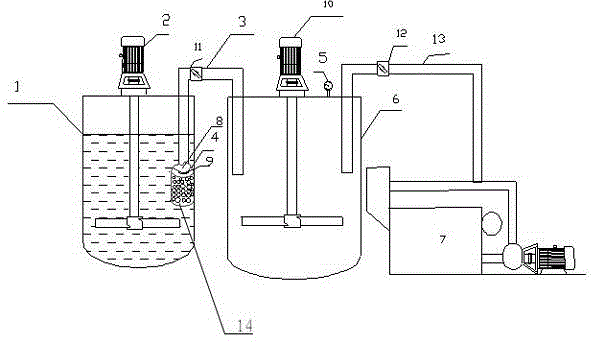

[0015] Example 1 like figure 1 Shown: a suction filtration device for preparing ammonium heptamolybdate with a negative pressure-resistant reactor, the common reactor 1 communicates with the negative-pressure-resistant reactor 6 through the infusion tube 3, and the negative-pressure-resistant reactor 6 communicates with the vacuum-resistant reactor 6 through the suction pipe 13 The vacuum unit 7 is connected, and the connecting pipe 8 is connected with the infusion pipe 3; the ordinary reactor 1 is equipped with a 1# stirring device 2 and a heating and heat preservation device, and the negative pressure resistant reactor 6 is equipped with a 2# stirring device 10 and a pressure gauge 5, which are movable. The inlet of the suction filter 4 under the common reactor 1 liquid level is connected with the outlet of the connecting pipe 8 .

[0016] The suction filter 4 is made up of a filter screen frame 14 and a filter cloth 9 wrapping the outer layer of the filter screen frame 14...

Embodiment 2

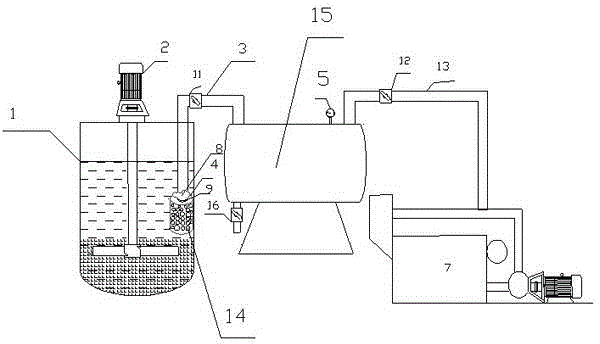

[0018] Example 2 like figure 2 Shown: a suction filter device with a liquid lifter for preparing high-concentration ammonium molybdate solution, the common reaction kettle 1 is connected to the liquid lifter 15 through the infusion pipe 3, and the liquid lifter 15 is connected to the vacuum unit 7 through the suction pipe 13 , the connecting pipe 8 communicates with the infusion pipe 3;

[0019] The suction filter 4 is made up of a porous filter screen frame 14 and a filter cloth 9 wrapping the outer layer of the filter screen frame. An infusion tube valve 11 is installed on the infusion tube 3 , and an inhalation tube valve 12 is installed on the inhalation tube 13 . The bottom of the liquid lifter 15 is provided with a lower valve 16 .

Embodiment 3

[0020] Example 3 like figure 1 Shown: adopt the filtration method of suction filter device described in embodiment 1 as follows:

[0021] The production process of ammonium heptamolybdate: using ammonium tetramolybdate and ammonia water as raw materials, add ammonium tetramolybdate to a certain concentration of ammonia water to dissolve, assist with stirring and heating, when the specific gravity, temperature and pH value of the solution reach a certain value When the dissolved ammonium molybdate solution is filtered, and then the solution is cooled, the ammonium heptamolybdate will be precipitated from the ammonium molybdate solution; when the crystals are precipitated to a certain extent, the solution is filtered to obtain the ammonium heptamolybdate product.

[0022] Adopting the described filtering method of embodiment 1 is: configure the high-concentration ammonium molybdate solution that meets the requirements in common reactor 1 mile, open 1# stirring device 2, 2# sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com