Air inlet filter

A kind of air intake filter and filter technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc. It can solve the problem that the sealing strip cannot be replaced, so as to solve the problem of non-replaceable, increase the installation and use space, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

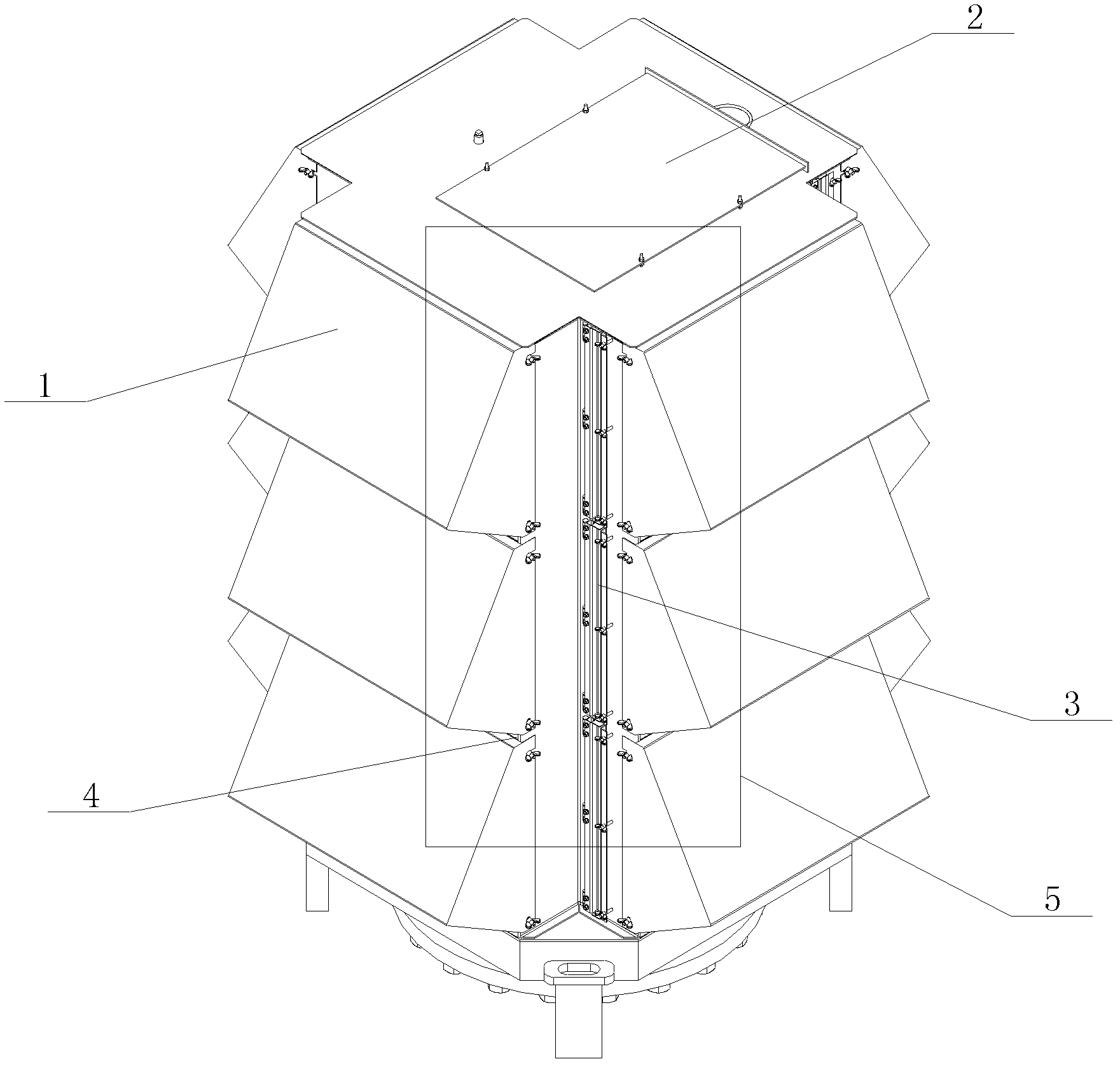

[0010] refer to Figure 1-2 , this specific embodiment adopts the following technical scheme: it includes a sheet metal shell 1, a removable baffle 2, a slot 3, a support plate 4 and a double-layer filter element 5, and the top of the sheet metal shell 1 is provided with a removable baffle The plate 2 is evenly provided with slots 3 on the side of the sheet metal shell 1 , the double-layer filter element 5 is arranged inside the sheet metal shell 1 , and a support plate 4 is arranged between the double-layer filter element 5 and the platinum shell 1 .

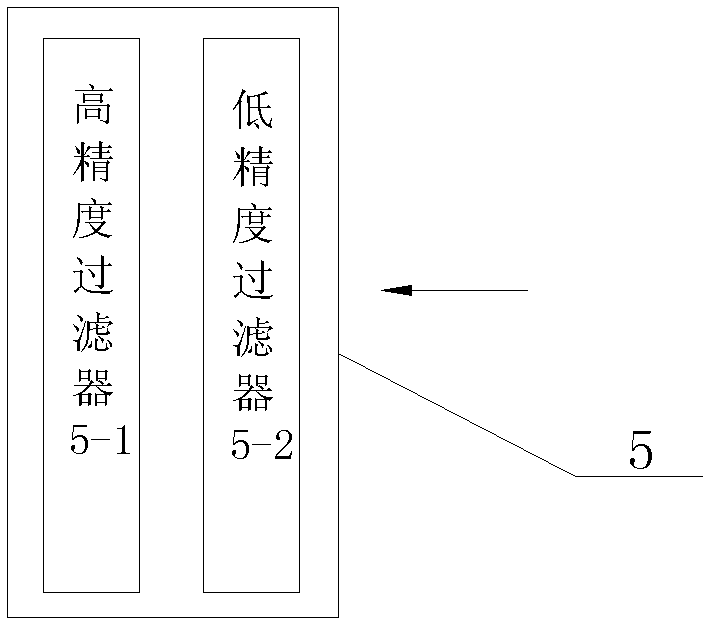

[0011] The double-layer filter element 5 includes a high-precision filter 5-1 and a low-precision filter 5-2, the low-precision filter 5-2 is arranged on the outer layer of the double-layer filter element 5, and the high-precision filter 5-1 is arranged on the The inner layer of the double-layer filter element 5.

[0012] This specific embodiment uses a double-layer filter element to filter, the outer layer can filter larger p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com