A fully enclosed aseptic liquid medicine ultrafiltration tank device

A fully enclosed, filter tank technology, used in ultrafiltration and other directions, can solve problems such as pollution, non-compliance with the new version of GMP airtight requirements, and difficulty in ensuring the quality of final products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

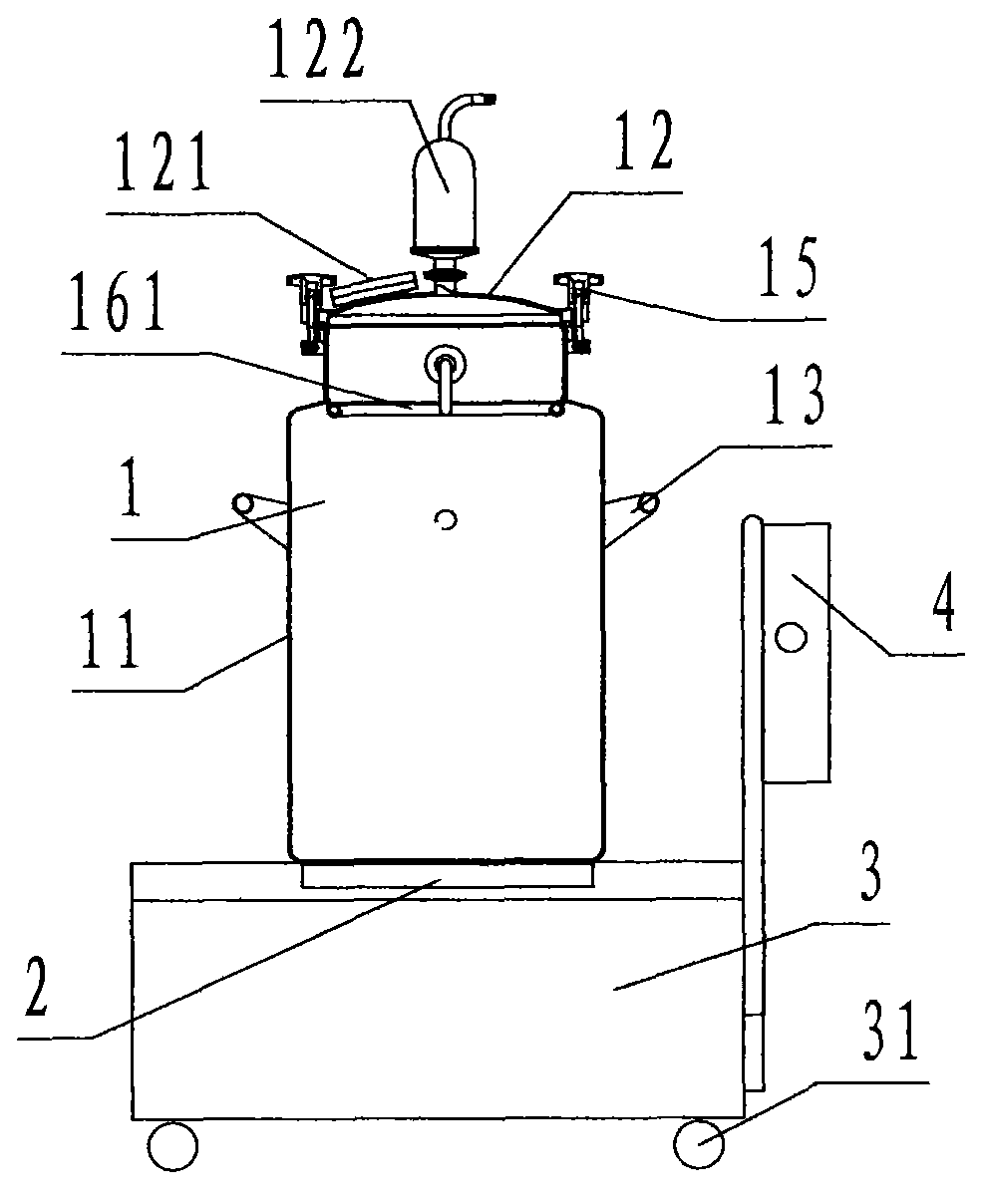

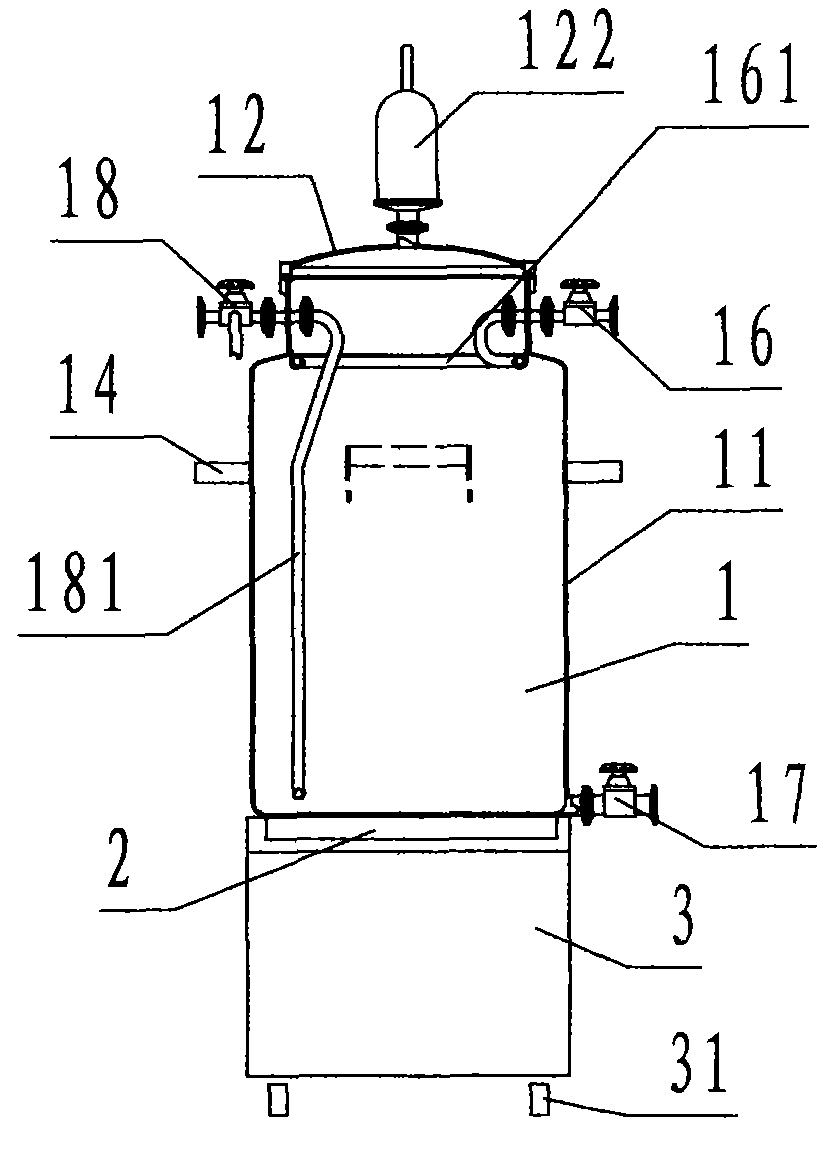

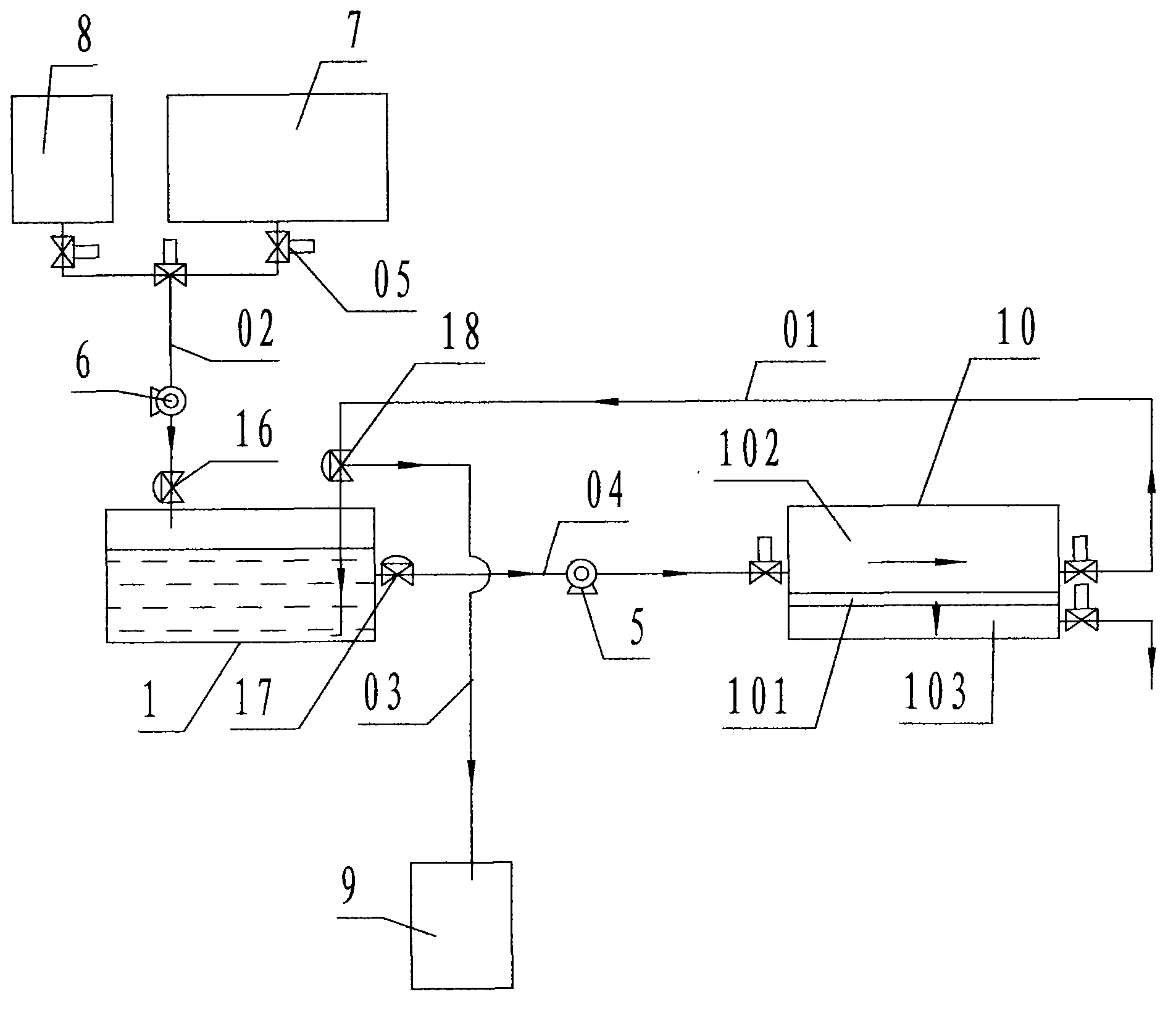

[0022] refer to Figure 1 ~ Figure 3 , a fully enclosed aseptic medicinal liquid ultrafiltration tank device of the present invention, comprising an ultrafiltration tank 1, an electronic scale 2, a support platform 3, and a controller 4, wherein: the ultrafiltration tank 1 is composed of a tank body 11 and a tank Cover 12, the tank body 11 is a hollow thin-walled cylindrical stainless steel container, the outer barrel wall of the tank body 11 is provided with a handle 13 symmetrically, and the outer barrel wall of the tank body 11 is provided with a protruding cylindrical handle symmetrically. The rotating shaft 14 and the upper edge of the tank body 11 are evenly equipped with knob-type lid lockers 15; the front outer wall of the upper part of the tank body 11 is provided with a three-way reversing diaphragm valve communicating with the inner cavity of the tank body 11 Referred to as the liquid return valve 18, the end of the liquid return valve 18 located in the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com