Method for extracting iron ore concentrate under anhydrous condition

An iron ore concentrate powder, anhydrous technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of limiting the scale of iron ore resource mining in arid areas, consuming large water resources, and high extraction costs. The effect of reducing water pollution, improving production efficiency and reducing extraction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

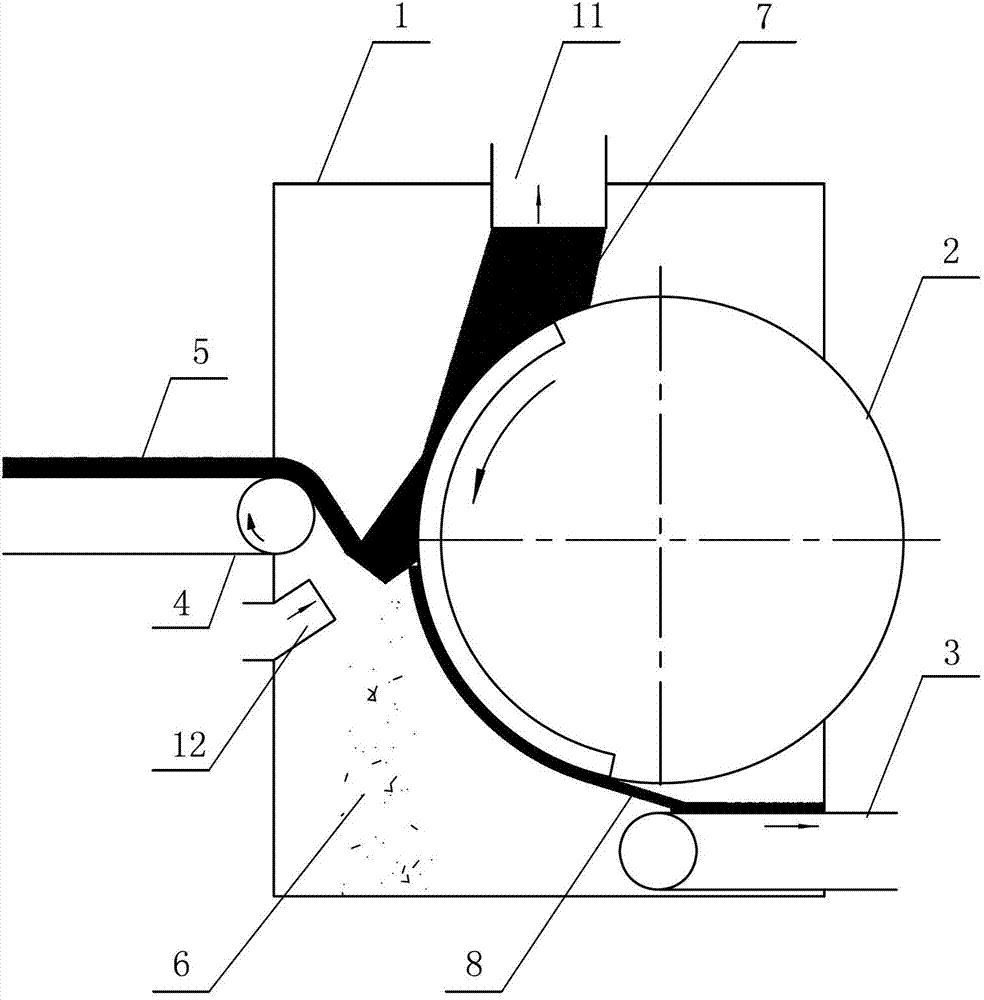

[0028] The present invention will be further described without limitation in conjunction with the accompanying drawings and examples below.

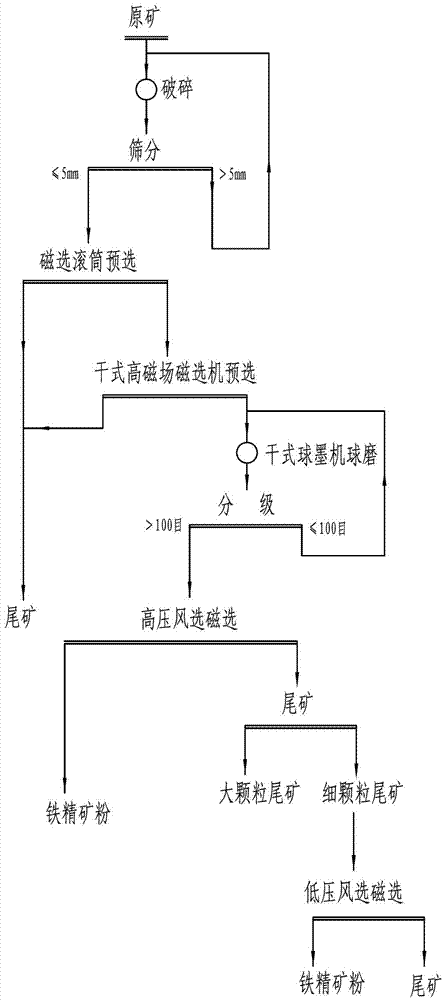

[0029] figure 1 Shown is the technical process of the method for extracting iron concentrate powder under anhydrous conditions of the present invention, and the method for extracting iron concentrate powder under anhydrous conditions of the present invention comprises the following steps:

[0030] (1) Crushing: Use a crusher to crush the raw ore to obtain raw ore particles. The crusher in this embodiment adopts a jaw crusher, which has high crushing efficiency and is used for coarse crushing of raw ore.

[0031] (2) Screening: Use a vibrating screen to screen the raw ore particles. The vibrating screen in this embodiment adopts a circular vibrating screen, which is a new type of high-efficiency vibrating screen with reliable structure, strong excitation force, high screening efficiency, low vibration noise, sturdy and durable, convenie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap