Device for forming metal carrier

A technology of metal carrier and internal rotation, which is applied in the field of forming processing equipment, can solve the problems of low production efficiency, low pass rate, and failure to meet quality requirements, etc., to achieve improved production efficiency, less extrusion deformation, and high flatness of the end surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

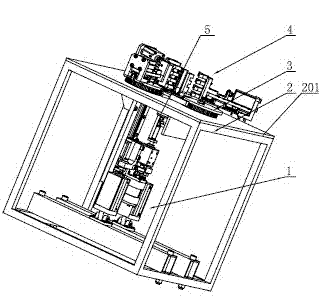

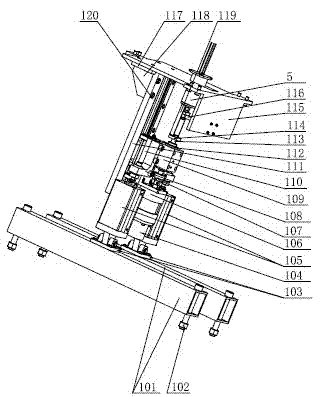

[0027] Such as figure 1 As shown, the present invention includes a frame 2 and a control system (not shown in the figure), and the pushing mechanism 1 is fixedly installed in the frame 2 . Such as figure 2 As shown, the push and turn mechanism 1 includes two mounting brackets 101 that are symmetrically installed and fixedly connected to the frame 2 by bolts 102. The piston rod of cylinder 105 is connected with motion plate 110 by cylinder push plate 108 respectively, and motion plate 110 is connected with slide mechanism 111 respectively, and slide mechanism 111 is installed on the supporting plate 120, and supporting plate 120 is connected with trapezoidal block 118 and flat plate 117 and The fixing frame 115 is connected. Located between the two pushing and turning cylinders 105, the base 106 is fixedly connected to the moving plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com