Die set capable of decreasing forming processes

A module and process technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low product efficiency, increased cost, cumbersome process, etc., and achieve the effect of improving efficiency, reducing cost and reducing molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

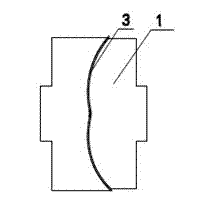

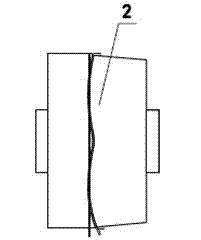

[0011] The present invention discloses a module that can reduce the molding process, the module includes two sets of moulds, such as figure 1 As shown, the molding arc of the upper and lower molds of the first set of mold 1 after closing is larger than the arc of the desired molded product, and the molding arc of the upper and lower molds of the second set of mold 2 is smaller than the arc of the desired molded product . The forming arc of the first set of molds is 5° greater than the arc of the required forming product, and the forming arc of the second set of molds is 3° less than the arc of the required forming product

[0012] The use process of the present invention is briefly described below:

[0013] First, the workpiece 3 to be formed is placed in the first set of molds 1, and the first step is to press the workpiece into a workpiece whose curvature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com