Large-span box girder forming die and forming process

A forming mold and large-span technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as improper chiseling methods, uneven strength, and manpower consumption, and achieve material resources and construction cycle savings. Wet joints Uniform connection surface, easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

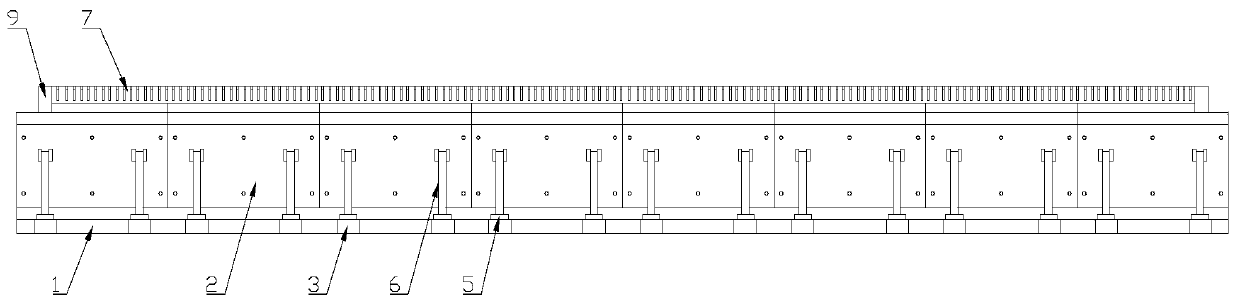

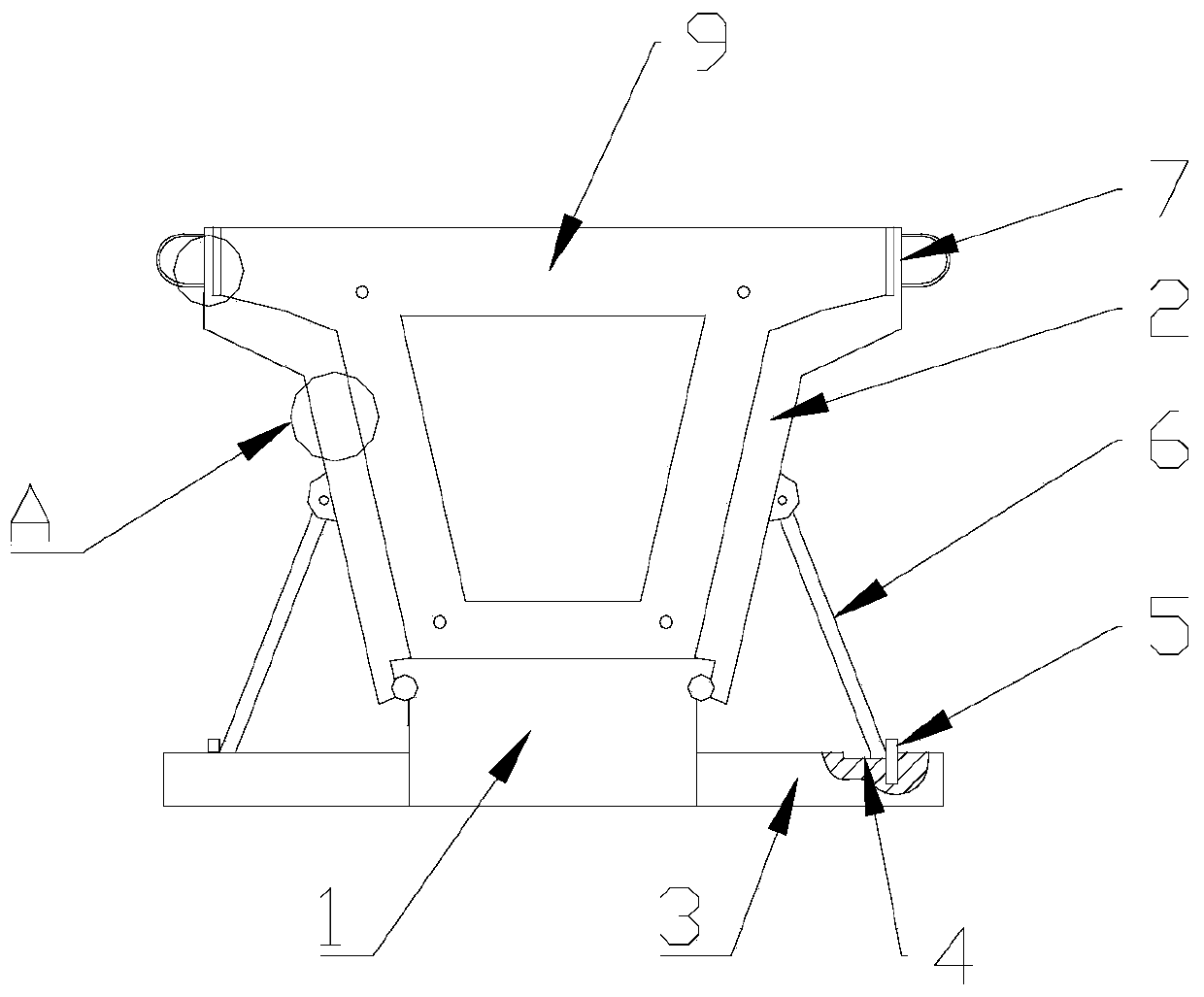

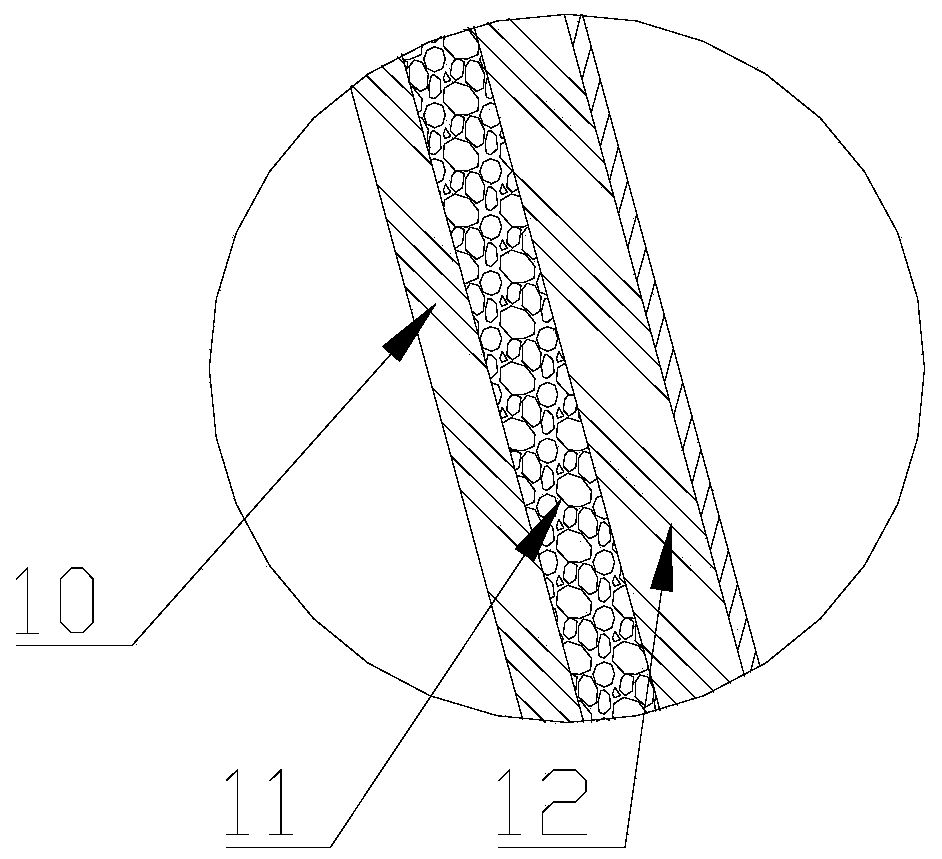

[0035] As attached in the manual Figure 1 to Figure 4 The molding die for a long-span box girder shown includes a base 1 and a side plate 2, a number of pillow blocks 3 are fixed on the left and right sides of the bottom of the base 1, and a slot 4 is opened on the upper surface of the pillow block 3, and the slot 4 is inserted A limit block 5 is provided, several side plates 2 are continuously hinged on the left and right sides of the upper part of the base 1, and a strut 6 is hinged on the outside of the middle of the side plate 2, and the bottom end of the strut 6 presses against the limit block 5, and the top of the side plate 2 is fixed There is a wet joint baffle 7, and the inside of the wet joint baffle 7 is embedded with a continuous textured stainless steel plate 8.

[0036] In addition, end plates 9 are inserted and fixed at the front and rear ends of the base 1 , and the end plates 9 are closed and connected with the side plates 2 .

[0037] In order to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com