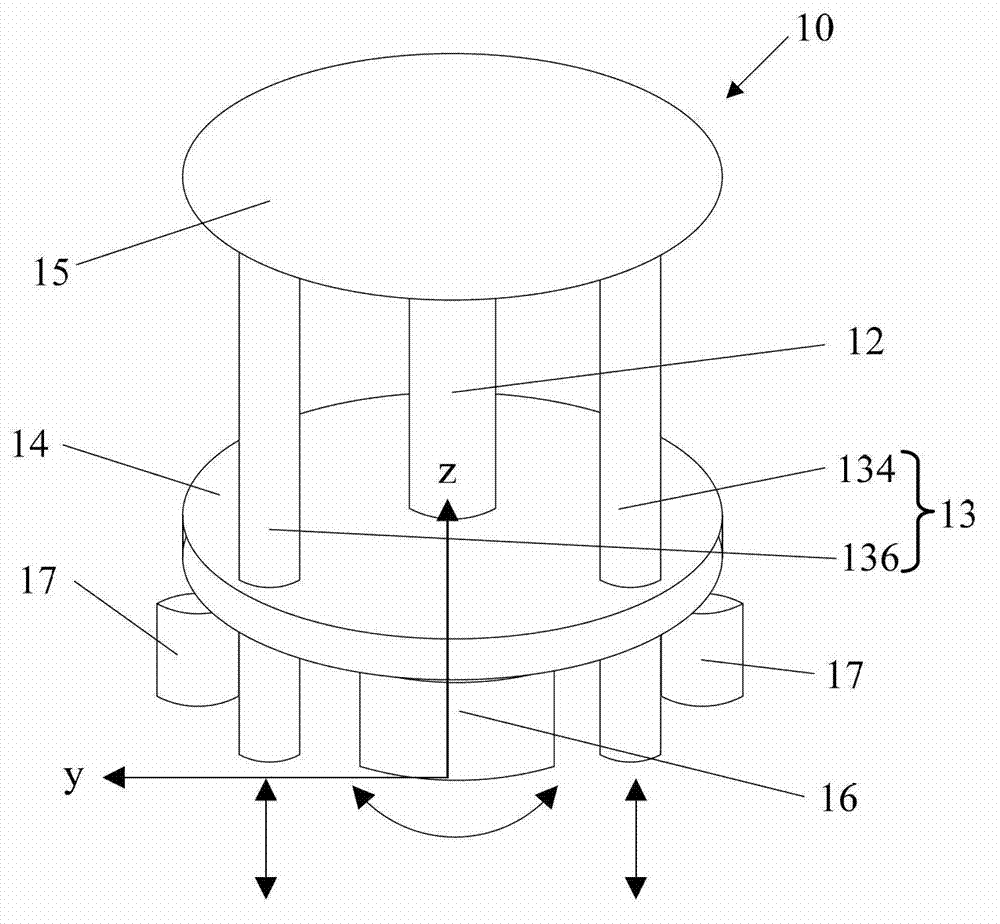

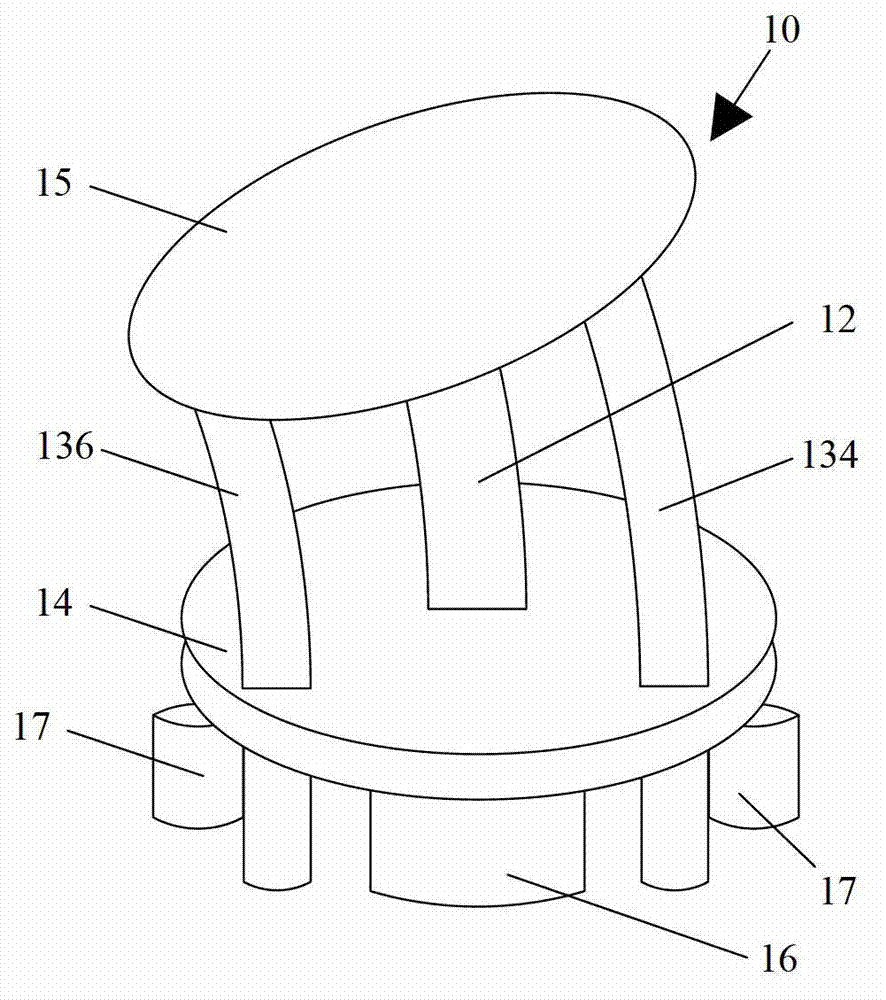

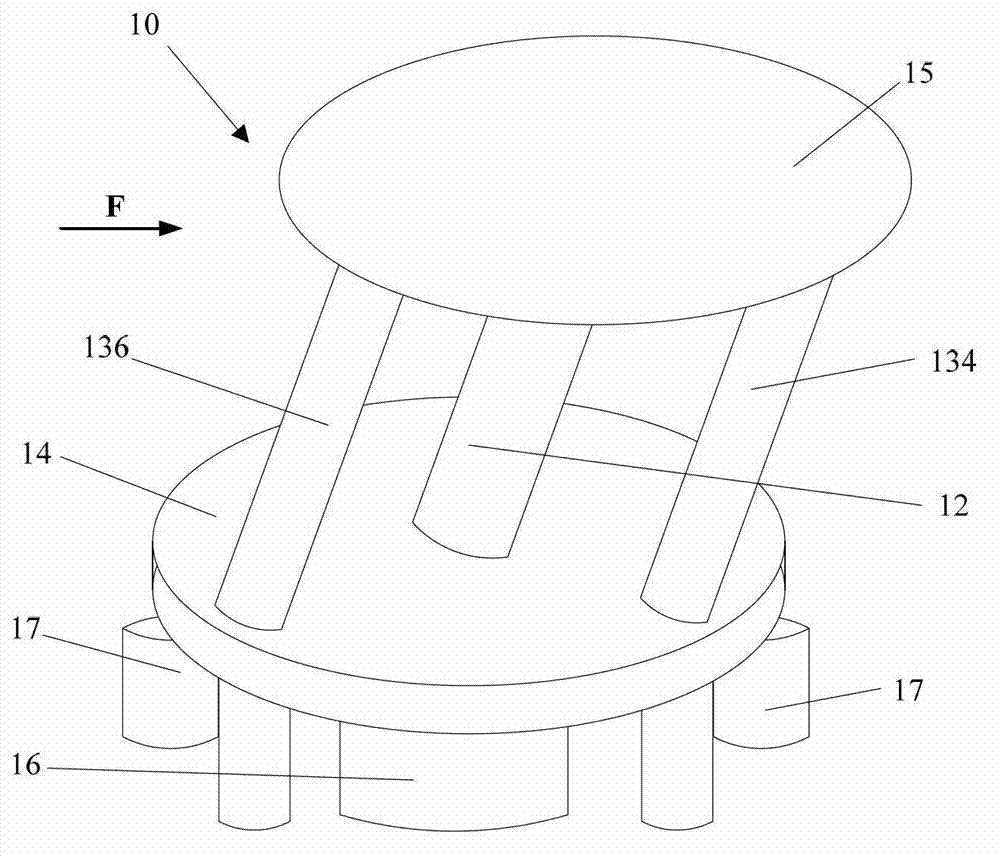

Three-degree-of-freedom movable joint mechanism and bionic robot

A technology of bionic robots and movable joints, which is applied in the field of bionic robots, can solve problems such as the compliance of robots, and achieve the effects of good safety, realism and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0039] Please also refer to Figure 7 with Figure 8 , the joint mechanism 10 includes a rotating wheel 18 connected between the second driver 17 and the first support member 134 , the rotating wheel 18 is axially connected with the second driver 17 and cooperates with the first support member 134 . When the second driver 17 is activated, it drives the rotating wheel 18 to rotate and provides the upward or downward thrust of the first support member 134, thereby adjusting the length of the first support member 134 between the first connecting member 14 and the second connecting member 15 , that is, the first supporting member 134 moves a certain distance between the first connecting member 14 and the second connecting member 15 . The thrust may be generated in a frictional manner.

no. 2 example

[0041] Please refer to Figure 9 , the joint mechanism 10 includes a gear 19 connected between the second driver 17 and the first support member 134 , and the gear 19 is axially connected with the second driver 17 . Each of the first support members 134 has a matching portion 1340 that cooperates with the gear 19 (the second support member 136 has a matching portion 1360 ), and the matching portion 1340 is disposed along the length direction of the first support member 134 . The matching parts 1340, 1360 can be any shape that fits with the gear 19, for example, when the gear 19 is a spur gear, the matching parts 1340, 1360 are designed as a straight tooth shape meshed with the gear 19; When it is a helical gear, the matching parts 1340 and 1360 are designed as a helical tooth shape meshed with the gear 19; but it is not limited to the enumerated shapes. When the second driver 17 is activated, the gear 19 is driven to rotate, and the gear 19 and the matching portion 1340 are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com