Packaging bag edge sealing device

An edge-sealing device and packaging bag technology, which is applied in packaging, packaging sealing/fastening, transportation packaging, etc., can solve problems such as shortening life, reducing edge quality, and damage to edge-sealing mechanisms, so as to prolong service life and improve sealing Edge quality, the effect of avoiding hard impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

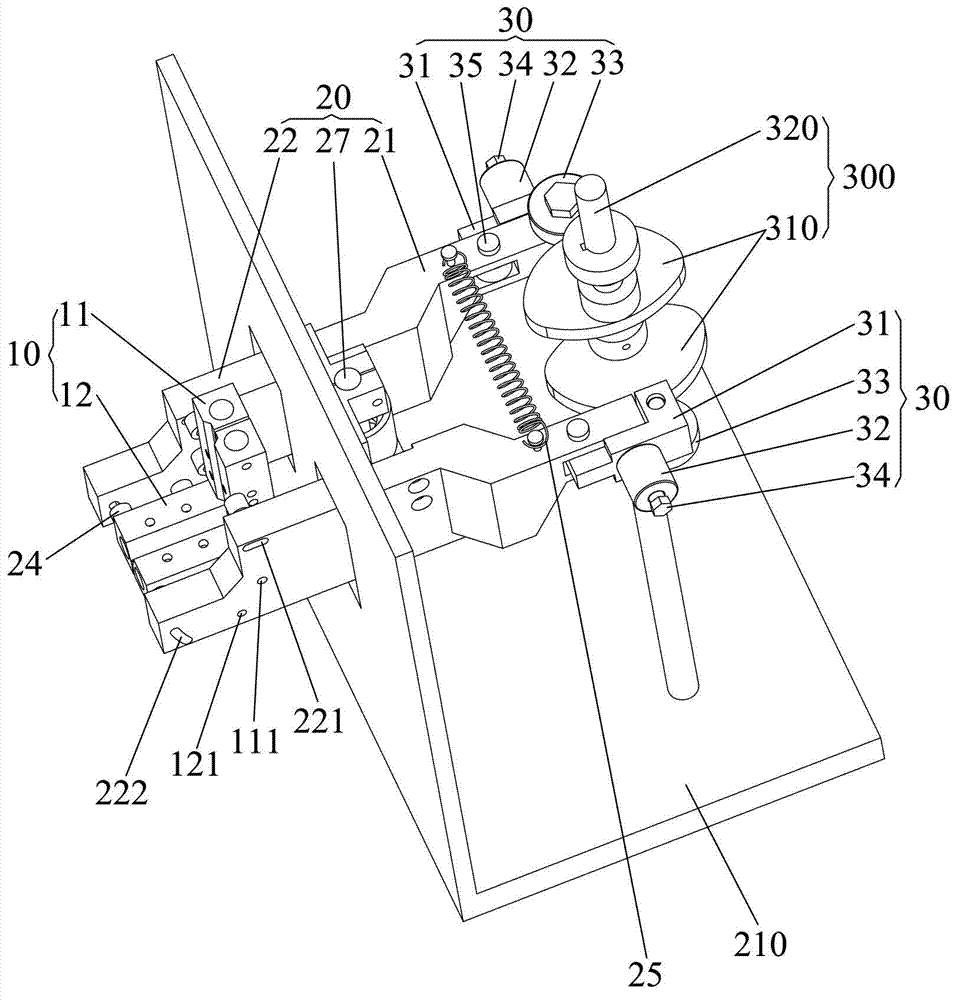

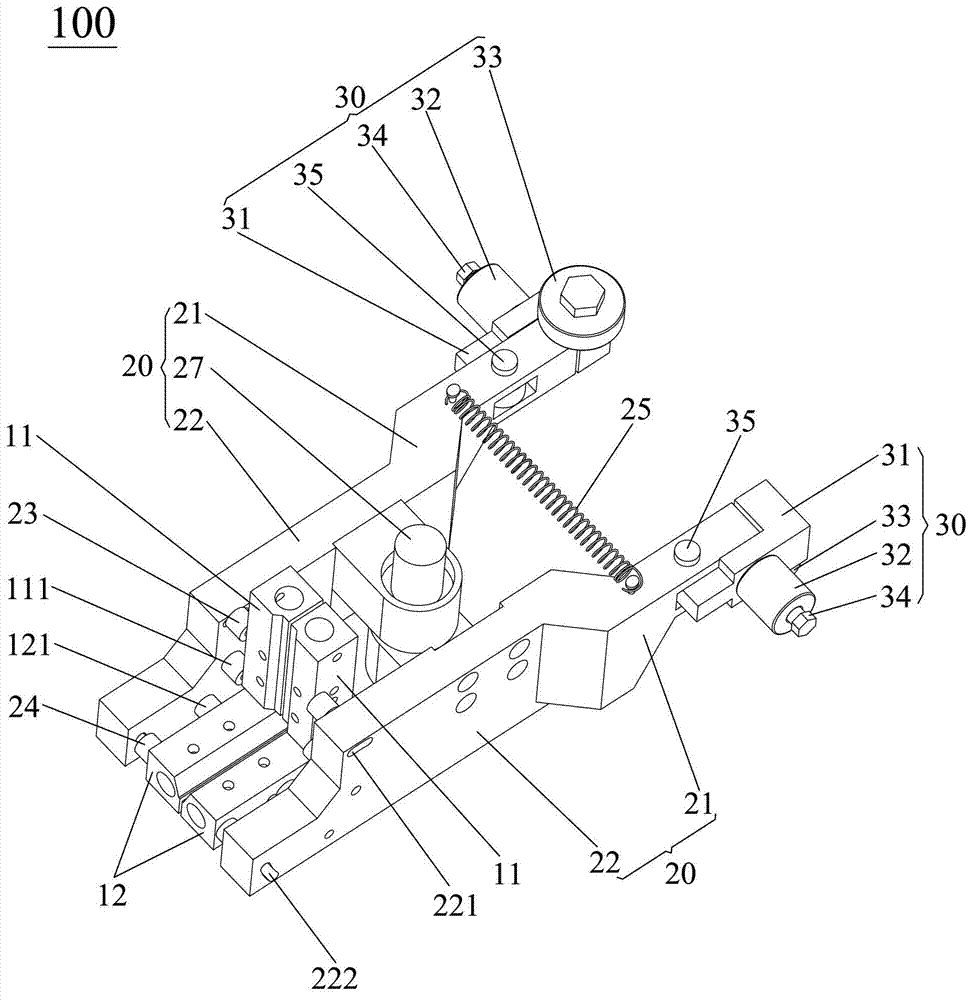

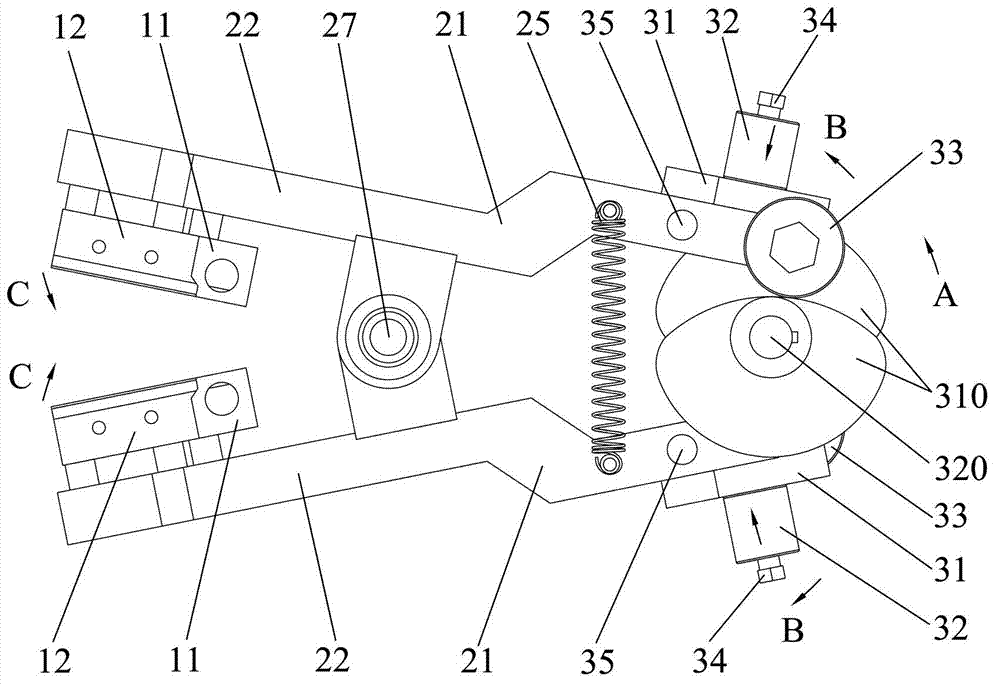

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0023] see figure 1 and figure 2 , the edge sealing device 100 of the packaging bag of the present invention is arranged on the frame 210 of the packaging machine and performs edge sealing on the packaging material strips delivered by the packaging machine, so that the packaging machine can process the packaging material strips one by one. bags together. Wherein, the edge sealing device 100 of the packaging bag of the present invention cooperates with the cam mechanism 300 in the packaging machine, so that the cam mechanism 300 can provide the power required for driving the edge sealing device 100 of the packaging bag of the present invention, and the packaging bag of the present invention The edge banding device 100 includes an edge banding assembly 10 , two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com