Paper stripping deice of engraved roll of folding machine

A folding machine and roller technology, used in transportation and packaging, sending objects, thin material handling, etc., can solve problems such as affecting printing production, clogging, baffle backlog, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solutions of the present invention, detailed descriptions are given below through specific embodiments and in conjunction with the accompanying drawings:

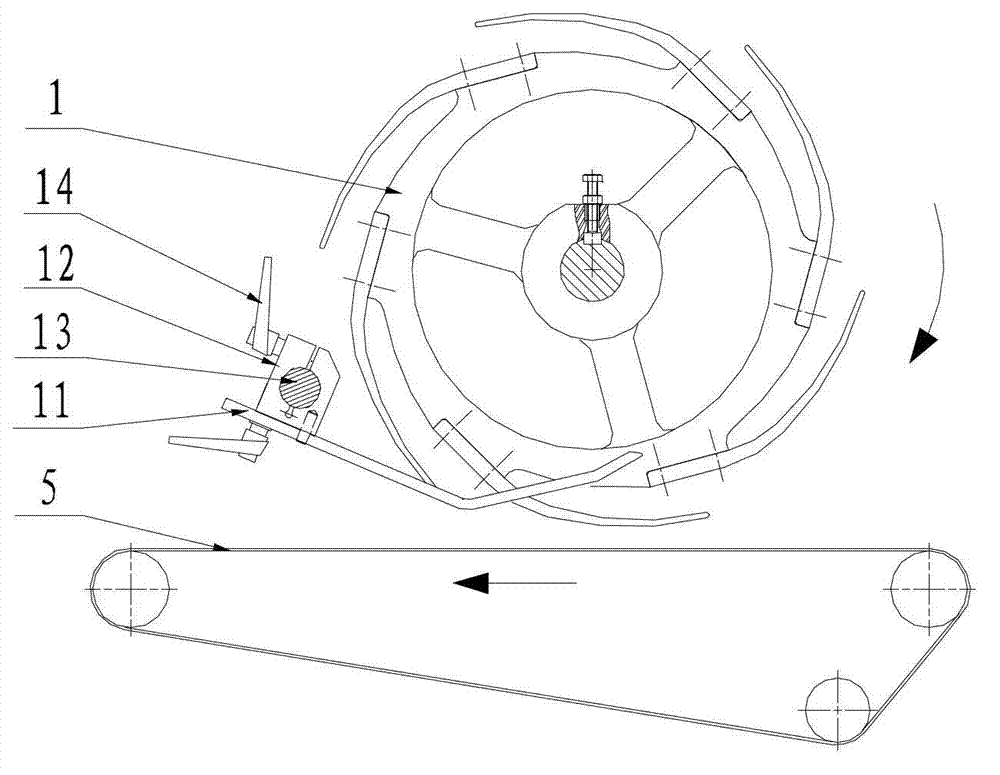

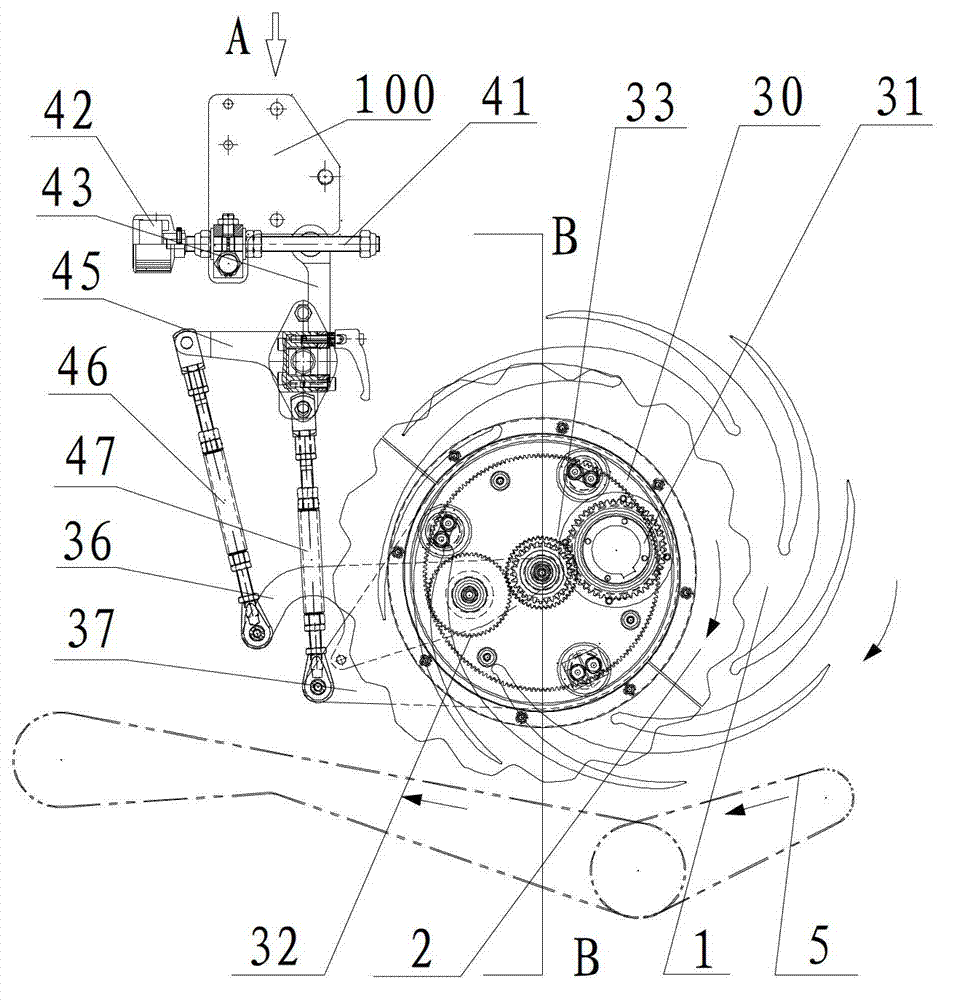

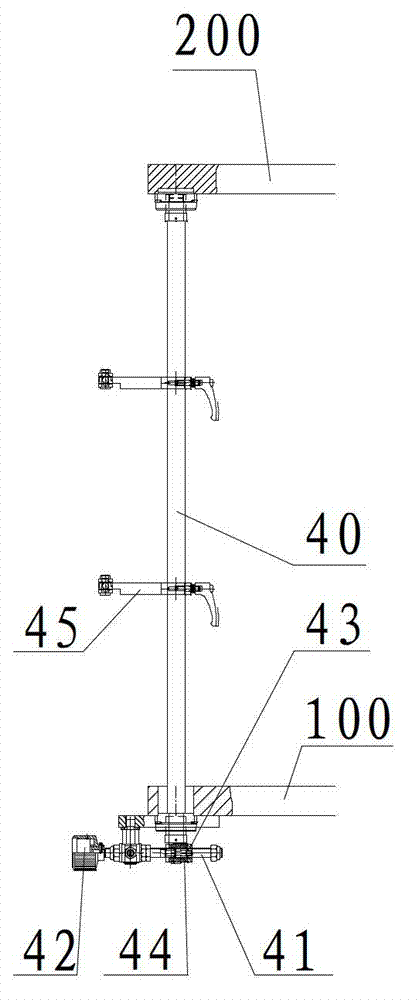

[0017] see Figure 2 to Figure 4 , The paper stripping device of the pattern drum of the folding machine of the present invention includes a mandrel 10 for installing the pattern drum 1, a peeling wheel 2, a gear pair deceleration mechanism and an adjustment mechanism for the peeling wheel 2.

[0018] The peeling wheel 2 is eccentrically arranged with the pattern drum 1 through a gear pair reduction mechanism. The peeling wheel 2 is made of nylon material, and the outer surface of the peeling wheel 2 is provided with transverse concave-convex patterns. For easier installation and disassembly, the peeling roller is surrounded by two semi-circles.

[0019] The gear pair reduction mechanism includes an internal gear 30, a driving gear 31, a transmission gear 32 and a double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com