Device and method for preparing high-purity oxygen gas based on chemical-loop air separation technique

An air separation and chemical chain technology, applied in oxygen production, energy input and other directions, can solve the problems of low oxygen purity, low output and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

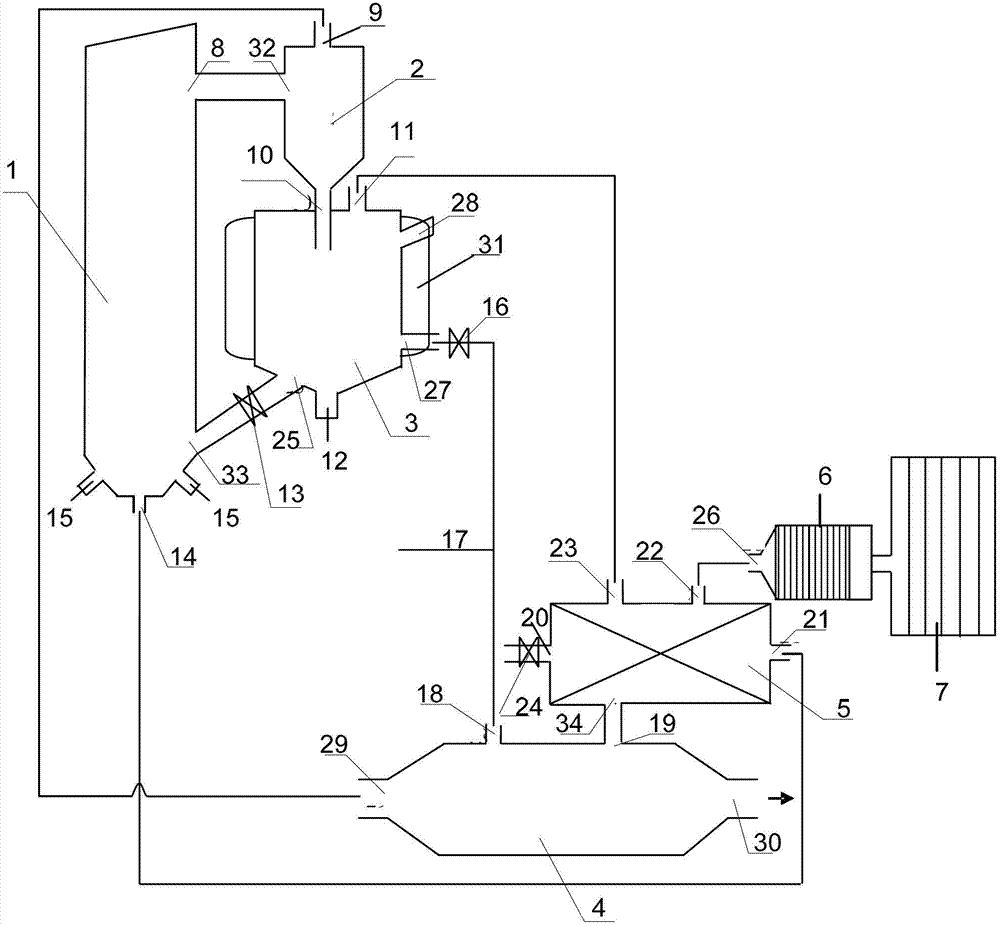

[0035] A device for preparing high-purity oxygen by chemical looping air separation technology, such as figure 1As shown, it includes a fluidized bed 1, a cyclone separator 2, a fixed bed 3, a waste heat boiler 4, a condenser 5, a bag filter 6 and a gas storage cabinet 7, wherein the fluidized bed exhaust port 8 is connected to the cyclone separator inlet The air port 32, the material leg 10 at the bottom of the cyclone separator 2 extends into the fixed bed 3 and is connected to the fixed bed 3, the fixed bed discharge port 25 is connected to the fluidized bed feed port 33, and the cyclone separator exhaust port 9 is connected to the waste heat Boiler flue gas inlet 29, waste heat boiler water vapor outlet 18 connected to fixed bed water vapor inlet 27, waste heat boiler condensed water inlet 19 connected to condenser condensed water outlet 34, cond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap