Traveling-rail-free type triangular hanging basket traveling construction method

A triangular hanging basket and construction method technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as inability to walk, easy sliding of gaskets, and high friction, so as to reduce the construction cost of the hanging basket and ensure safety , The effect of saving the walking time of the hanging basket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

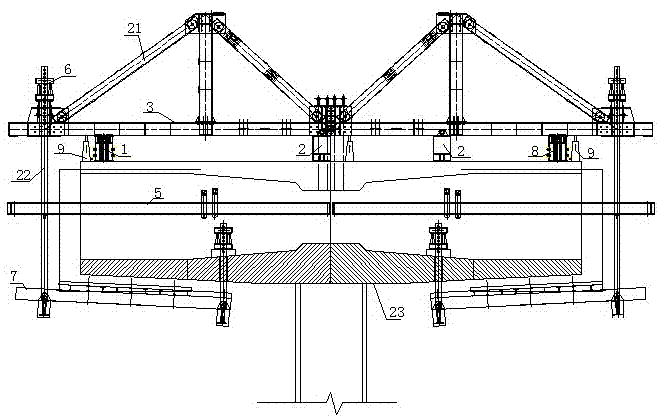

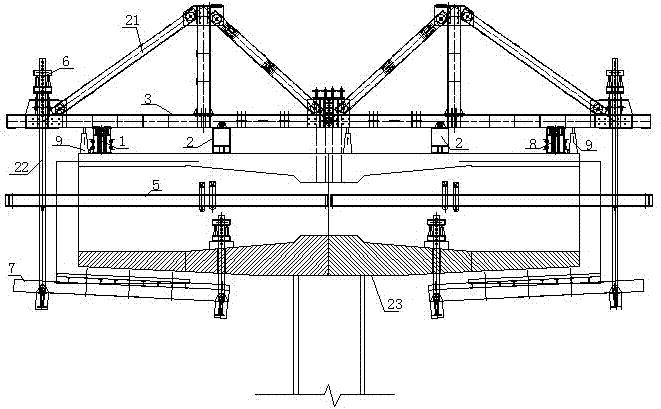

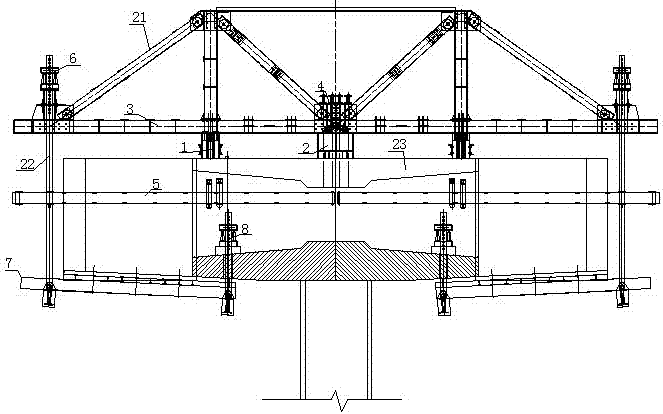

[0024] Depend on Figure 1-Figure 10 A walking construction method of a non-traveling rail-type triangular hanging basket is shown. The triangular hanging baskets are arranged in groups and there are two groups. Each group of triangular hanging baskets includes two triangular trusses 21 arranged at transverse intervals. The two inner triangular trusses 21 are connected by cross-links 17. Two sets of triangular hanging baskets are arranged symmetrically on both sides of the beam body 23 of the connecting beam. body 23, so two groups of triangular hanging baskets also walk in reverse along the continuous beam both sides respectively when walking. Each of the triangular trusses 21 is connected with a front hanging system 6, a rear hanging system 8, two inner sliding beams and two outer sliding beams 5, etc. at different positions, wherein the front hanging system 6 and the rear hanging system 8 are respectively used for connecting The front side and the rear side of the bottom m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com