Fan device driving gas to circulate in high-temperature high-pressure sealed pipeline

A high temperature and high pressure, gas circulation technology, used in pump devices, machines/engines, liquid fuel engines, etc., can solve problems such as low pressure resistance, increase coolers, etc., to reduce strength requirements, ensure reliability, and seal performance. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

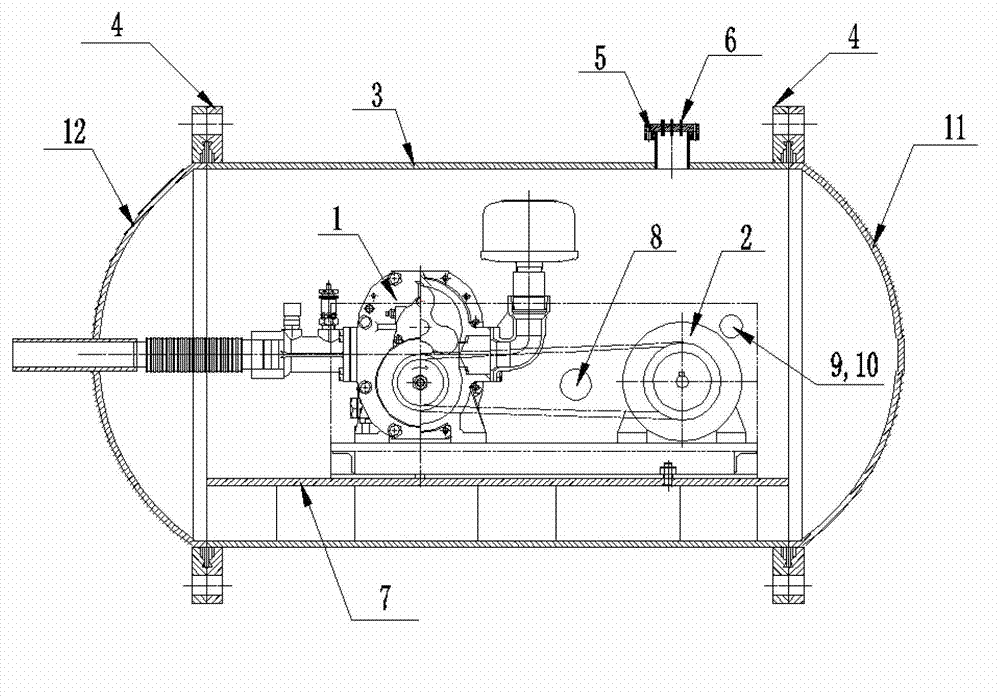

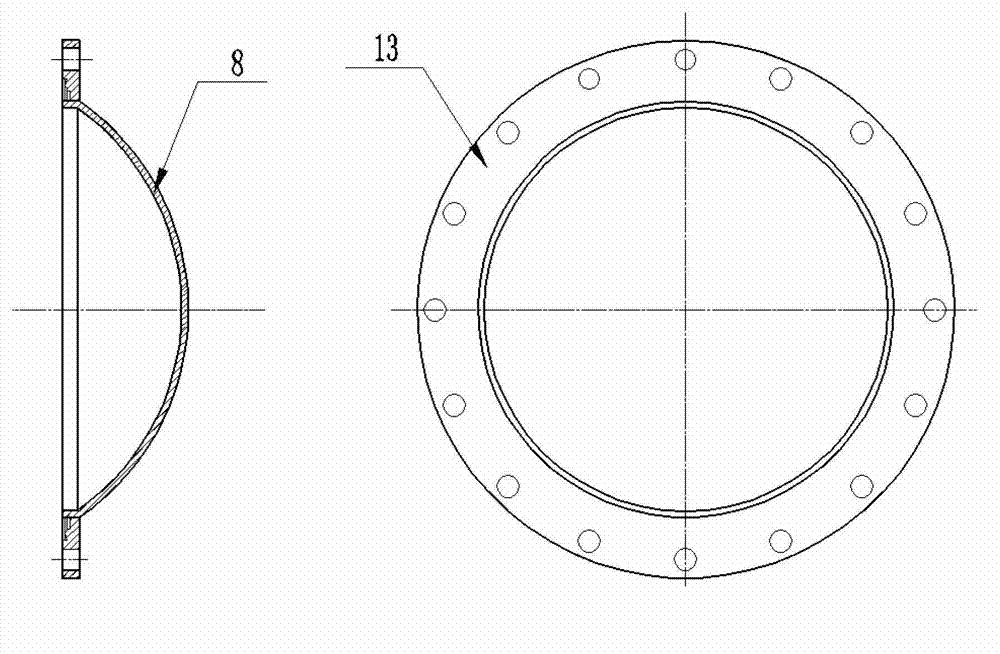

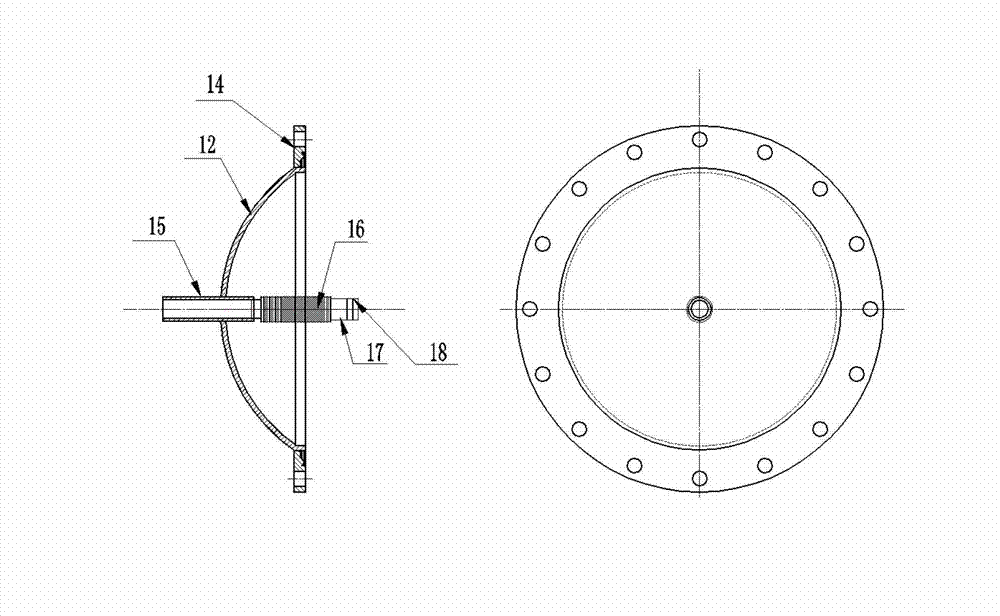

[0016] Such as Figure 1~3 As shown, when the pressure in the pipeline is lower than 3MPa, the fan 1 and the motor 2 are placed in the fan cover 3, and the fan support base 7 is welded in the fan cover 3, and the fan 1 and the motor 2 are fixed on the fan support base by bolts 7, the front end cover 11 of the fan cover and the rear end cover 12 of the fan cover are connected to the flange 4 of the fan cover through the flange 13 of the front cover of the fan cover and the flange 14 of the rear end cover of the fan cover, and rubber gaskets or Metal sealing gasket, each flange can use ordinary concave and convex flanges, the upper end of the fan cover 3 is connected to the lead flange 5, the lead flange is composed of two flanges, the upper flange acts as a seal, and the lower flange It plays the role of connection and sealing. The two flanges can be sealed with graphite or metal pads. The lead terminal 6 is welded on the upper flange of the lead flange 5. The main function of ...

Embodiment 2

[0019] Such as Figure 1~3 As shown, when the pressure in the pipeline is greater than 3MPa, the fan 1 and the motor 2 are placed in the fan cover 3, and the fan support base 7 is welded in the fan cover 3, and the fan 1 and the motor 2 are fixed on the fan support base 7 by bolts Above, the front end cover 11 of the fan cover and the rear end cover 12 of the fan cover are connected to the flange 4 of the fan cover through the flange 13 of the front cover of the fan cover and the flange 14 of the rear end cover of the fan cover. Rubber gaskets or metal gaskets are used between the connecting flanges. Gasket, each flange can use a knife-edge flange. The upper end of the fan cover 3 is connected with a lead flange 5. The lead flange is composed of two flanges. The upper flange acts as a seal, and the lower flange acts as a seal. Connection and sealing function, the two flanges are welded together, and the lead terminal 6 is welded on the upper flange of the lead flange 5. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com