Lubricating system of linear assembly

A technology for linear components and lubrication systems, applied in the field of lubrication systems, can solve problems such as excess oil overflow, pollution of linear components and working environment, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

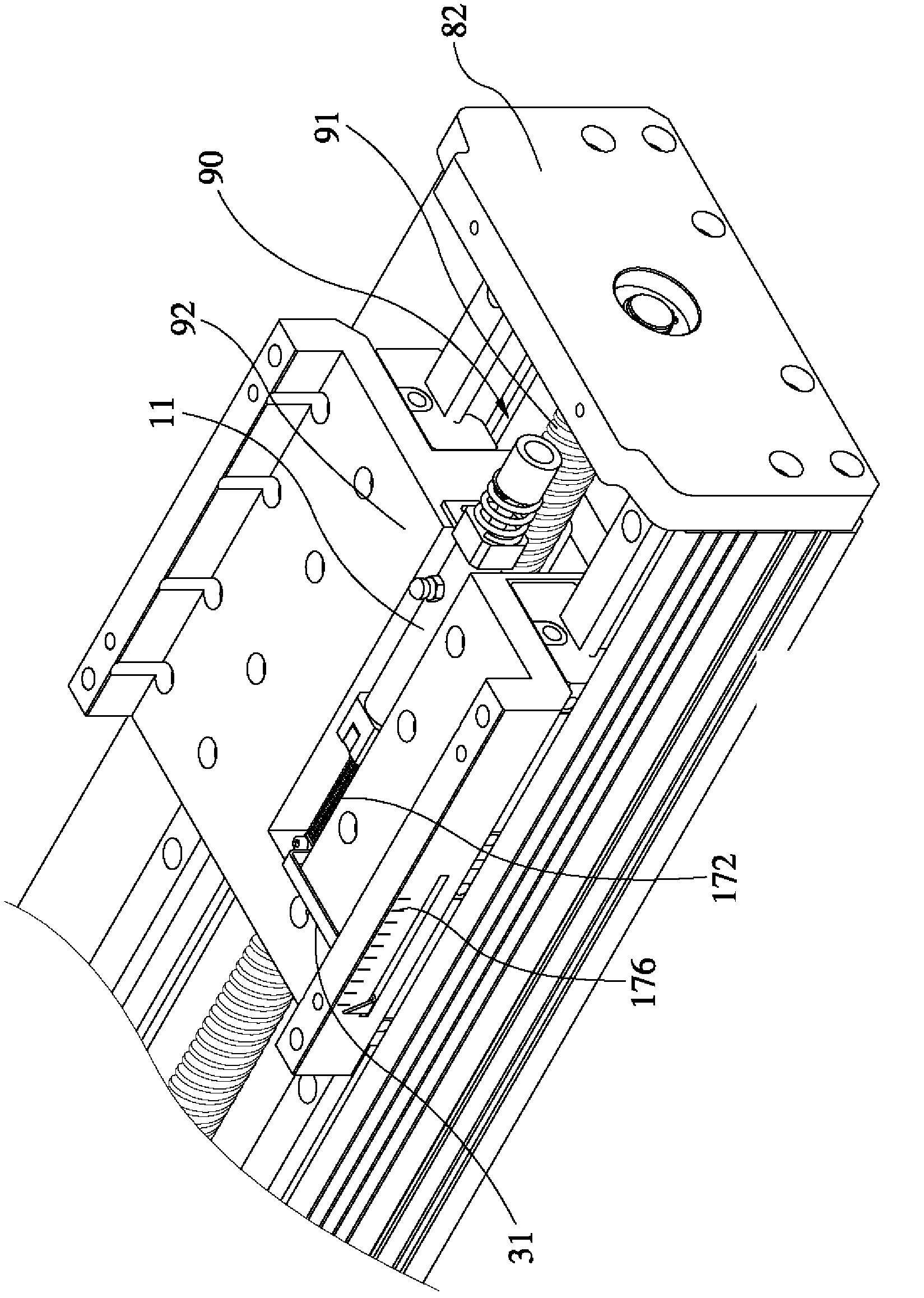

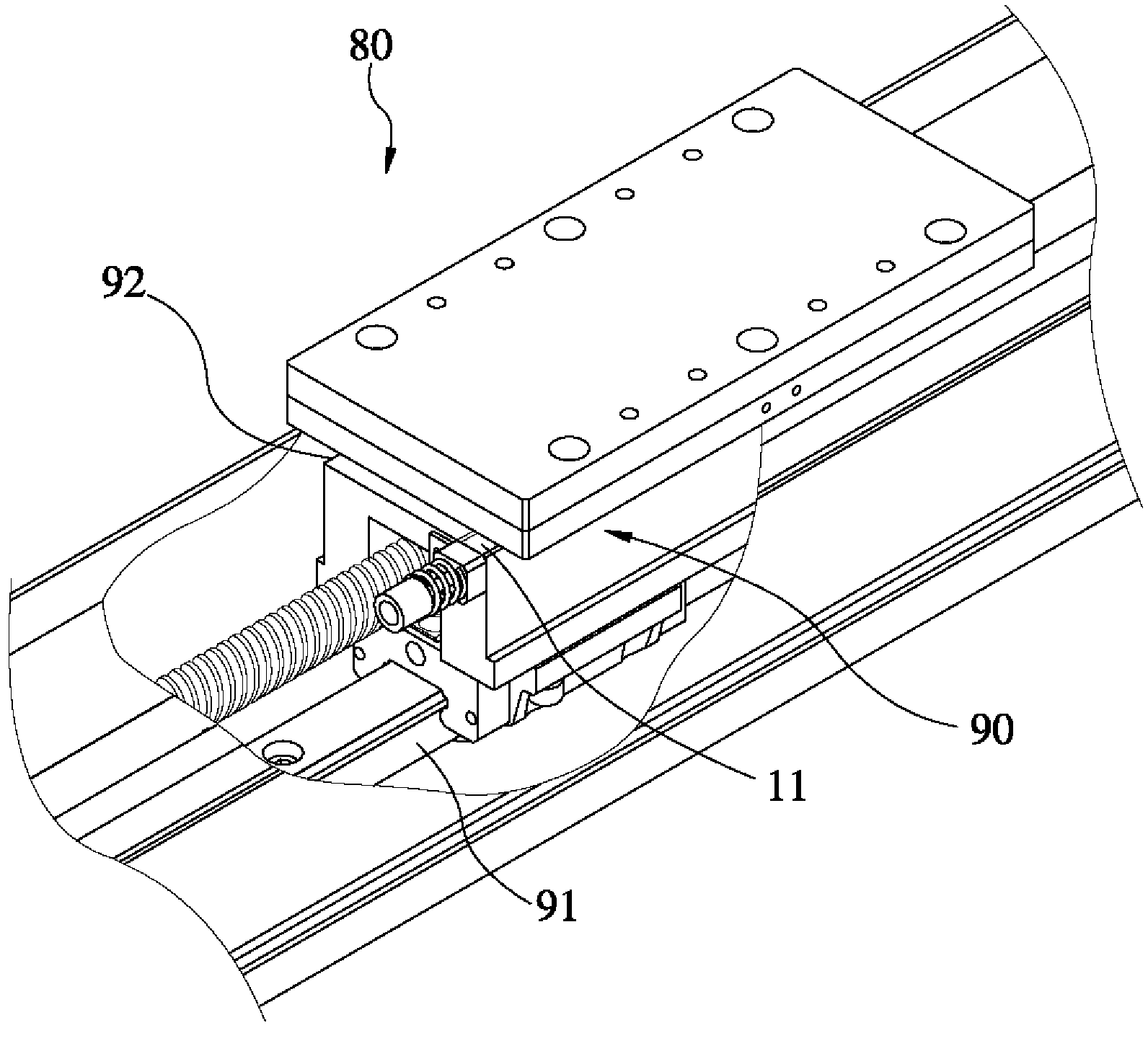

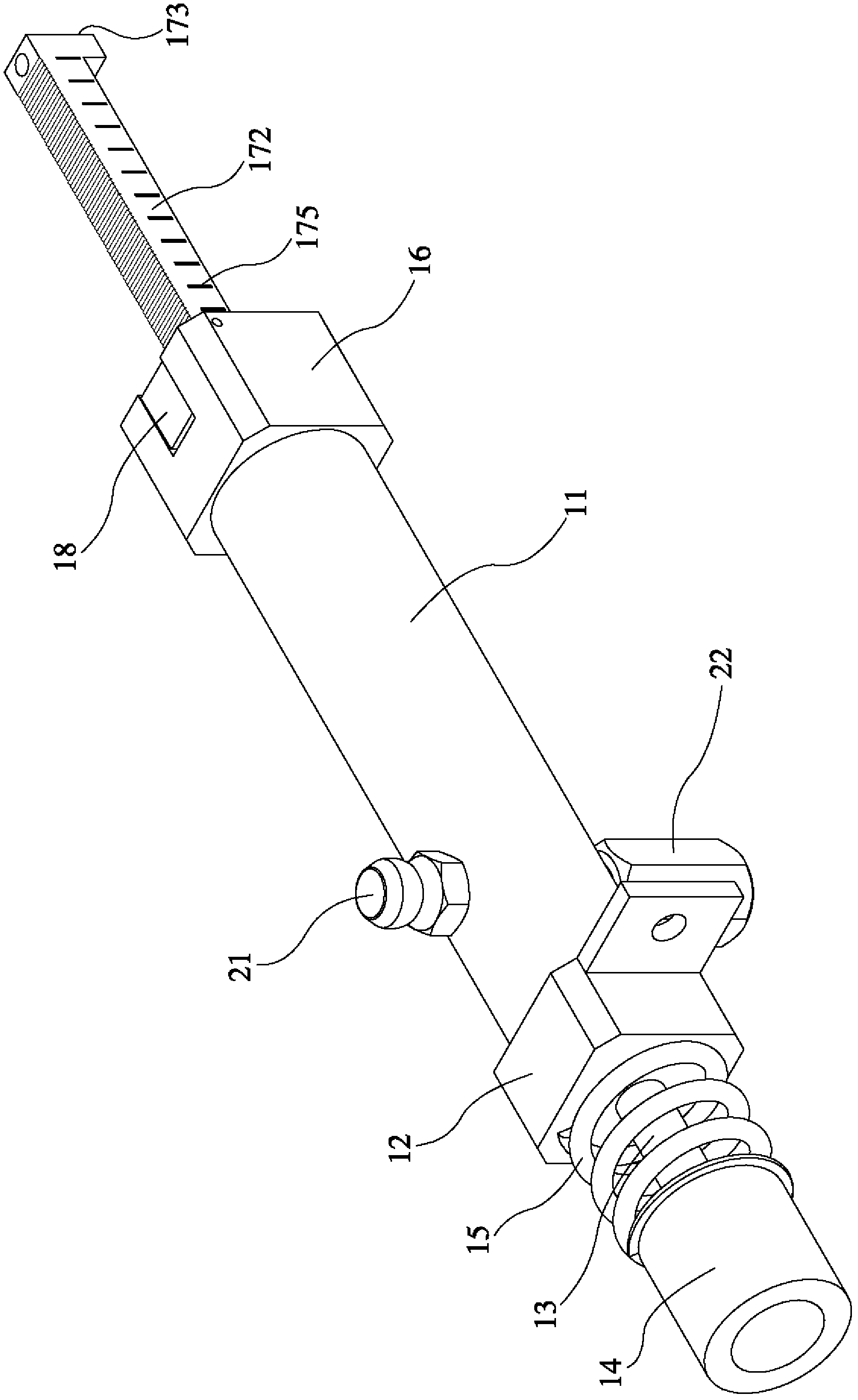

[0054] A lubrication system for a linear assembly provided by the present invention is provided in a linear assembly, the linear assembly has a long shaft and a moving body, the moving body is set on the long shaft and can reciprocate relative to the long shaft, the The lubrication system of the linear component is fixed on the mobile body, which includes: an oil storage tank, which is fixed on the mobile body, and its two ends are a first end and a second end respectively, and the oil storage tank has a an oil chamber; a first cover, which is set on the first end of the oil storage tube; a first piston rod, which has a first head and a first rod, and the first head matches the oil chamber Movably arranged in the oil chamber, the first rod passes through the first cover to expose the first cover; a stopper is arranged on the first rod; a first elastic member, the two ends are respectively Contacting the first cover and the stopper; a second cover, covering the second end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com