Transient waveform full voltage fault recording online detection device and working method thereof

A technology of fault recording and detection device, which is applied in the direction of using digital measurement technology for measurement, etc., can solve the problems of inability to detect transient voltage fault waves, harmonics, notch waves, flicker fault waves, etc. To achieve the effect of reasonable structure, convenient use and no influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

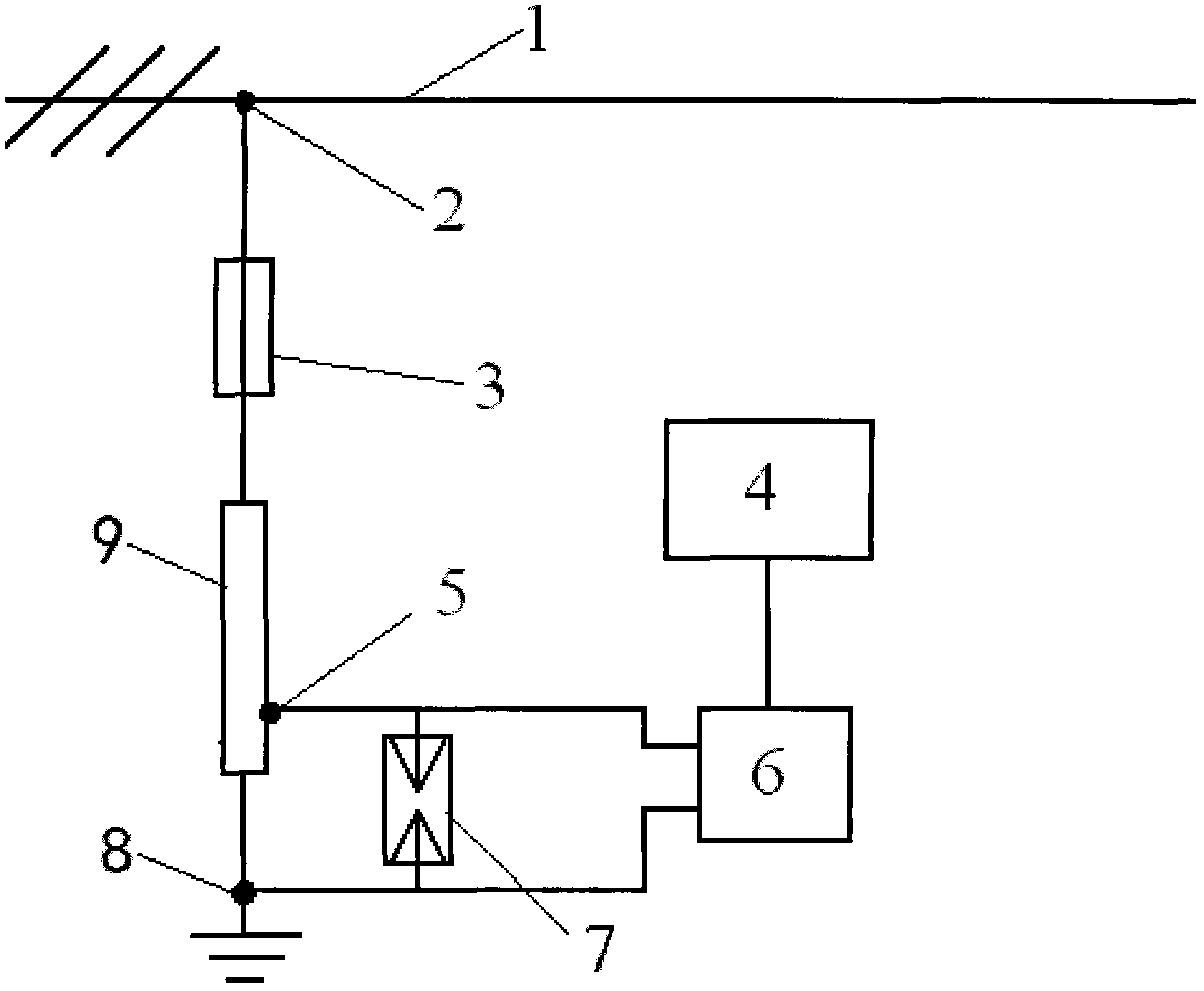

[0022] see figure 1 , the composition of the transient wave full-voltage fault recording online detection device is as follows: the non-inductive resistor divider 9 is equipped with a resistance ratio of 1000: 1 (can be between 1000~3000: 0.9~1.1, used to divide 10 ~ 35KV voltage division is ≤ 44V) Set the voltage division tap terminal 5, one end of the low resistance value after the tap is electrically connected to the ground terminal 8, and the other end is electrically connected to the high voltage terminal 2 through the non-inductive fuse 3; Wherein, the resistance value of the non-inductive resistor divider 9 is 10MΩ (can be between 10-35MΩ). A gas discharge tube 7 and a sampling card 6 with a sampling frequency ≥ 30 MHz / s are connected in parallel between the voltage divider tap terminal 5 and the ground terminal 8, and the output end of the sampling card 6 is electrically connected to the industrial controller 4; wherein, the gas discharge tube 7 The model of the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com