Capacitive touch panel and manufacture method thereof

A technology of capacitive touch and manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of different reflectivity of metal bridges, lower yield, and touch failure, etc. Achieve the effect of shortening conversion time, long service life and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

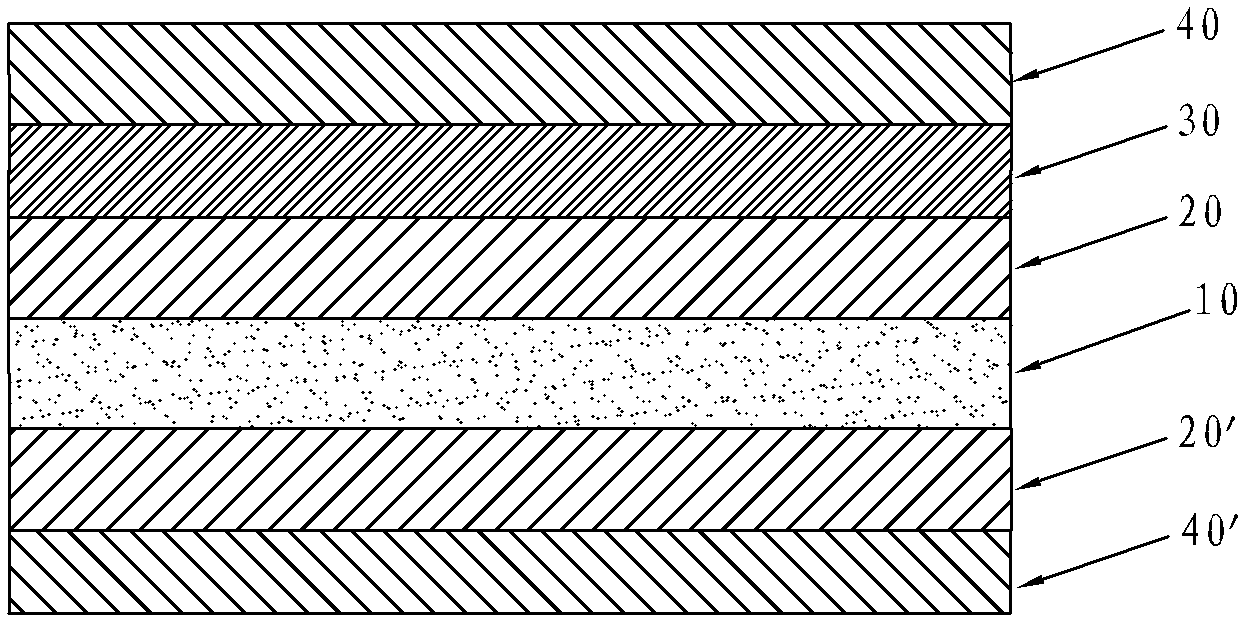

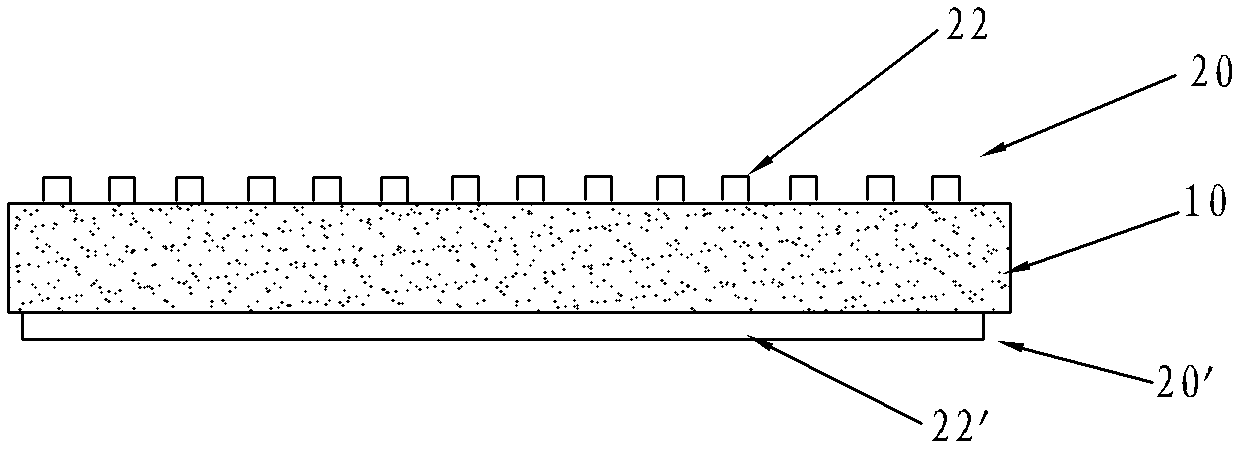

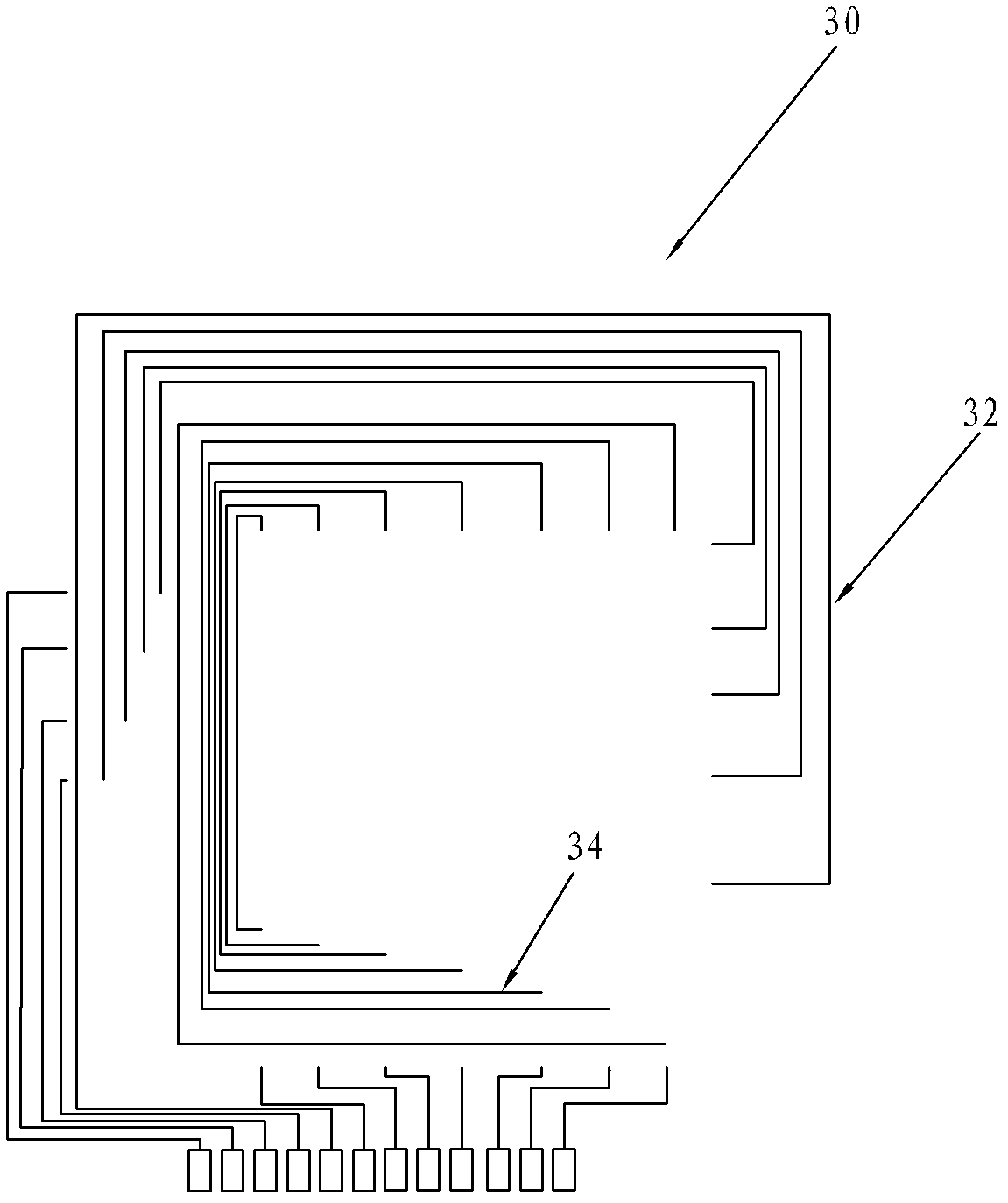

[0025] Such as figure 1 As shown, the capacitive touch panel of the present invention includes a glass substrate 10, a first transparent conductive layer 20, a second transparent conductive layer 20', a conductive metal layer 30, and two insulating layers 40, 40'; wherein, The glass substrate 10 has two surfaces, namely a first surface and a second surface. The first transparent conductive layer 20 is arranged in the middle of the first surface of the glass substrate 10, and the second transparent conductive layer 20' is arranged on the second surface o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap