T-shaped microwave switch driven by motor

A microwave switch and transmission group technology, applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of insufficient mechanical properties of motor-type microwave switches, achieve fast action speed, improve response speed, and improve vibration and shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

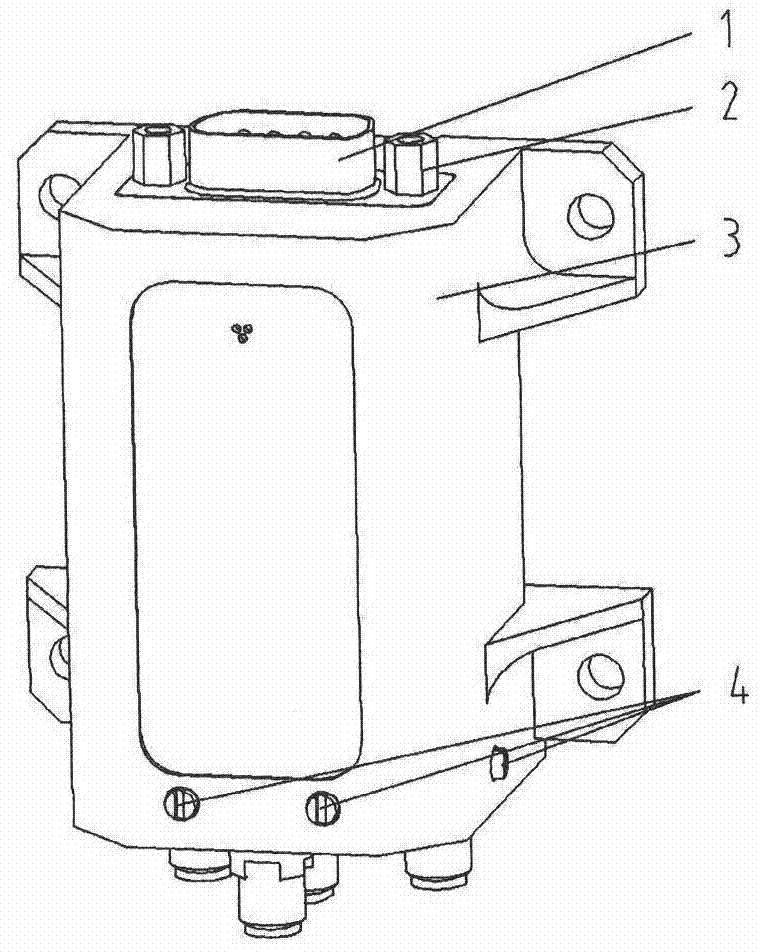

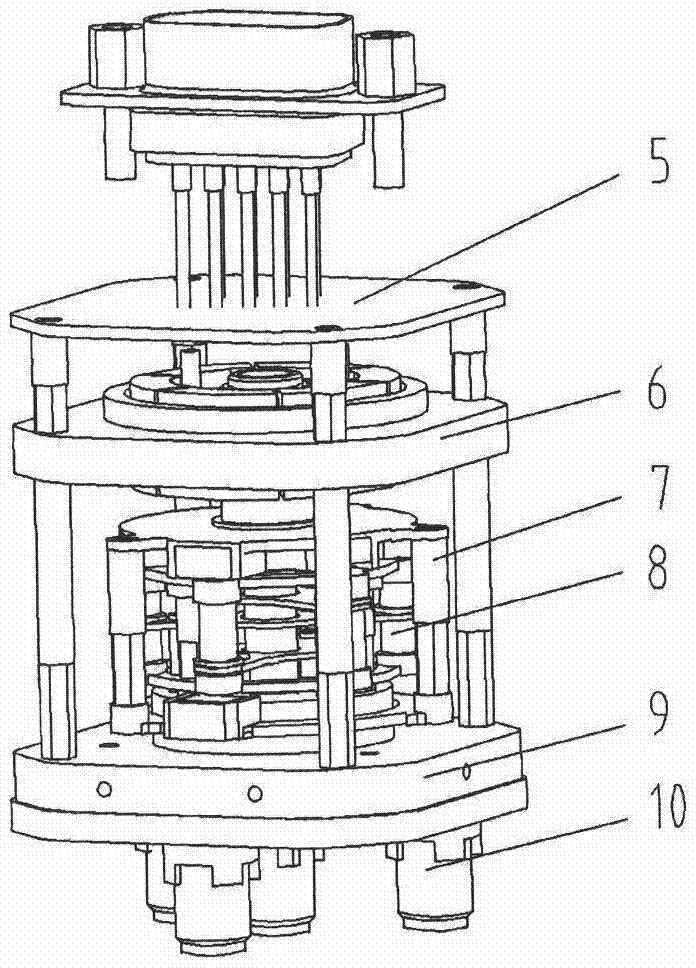

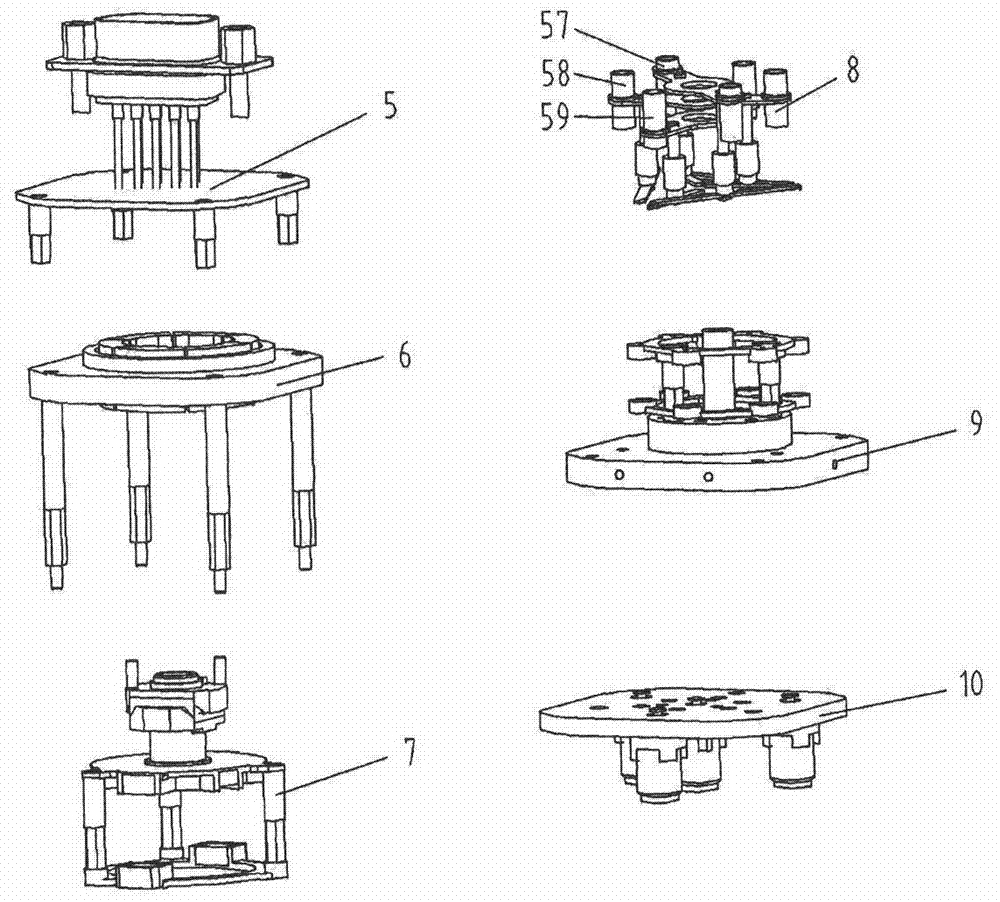

[0021] Such as figure 1 , 2 , 3, the T-type microwave switch of the present invention includes a d-sub connector 1, a housing group 3, a circuit board group 5, a stator group 6, a rotor group 7, a transmission group 8, a cover group 9 and a base group 10. . The circuit board group 5 , the stator group 6 , the rotor group 7 , the transmission group 8 and the cover plate group 9 are all located inside the shell group 3 . The d-sub connector 1 is fastened to the housing group 3 by mounting screws 2 , and the housing group and the cover board group 9 are fixed together by screws 4 . The circuit board group 5 is fixed above the stator group 6 , and the stator group 6 is fixed on the cover plate group 9 . The base set 10 is installed under the cover plate set 9 . The rotor set 7 and the transmission set 8 are arranged between the stator set 6 and the cover plate set 9 , and the drive set 8 and the cover plate set 9 are assembled together.

[0022] Such as Figure 4 As shown, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com