S-shaped spoke plate track wheel blank cast and casting method thereof

A technology of spoke plates and wheels, which is applied in the field of casting and casting of S-shaped spoke rail wheel blanks, can solve the problems of low density of wheels, waste of materials, and low process yield, and achieve fine tread structure and use Long life and dimensionally accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

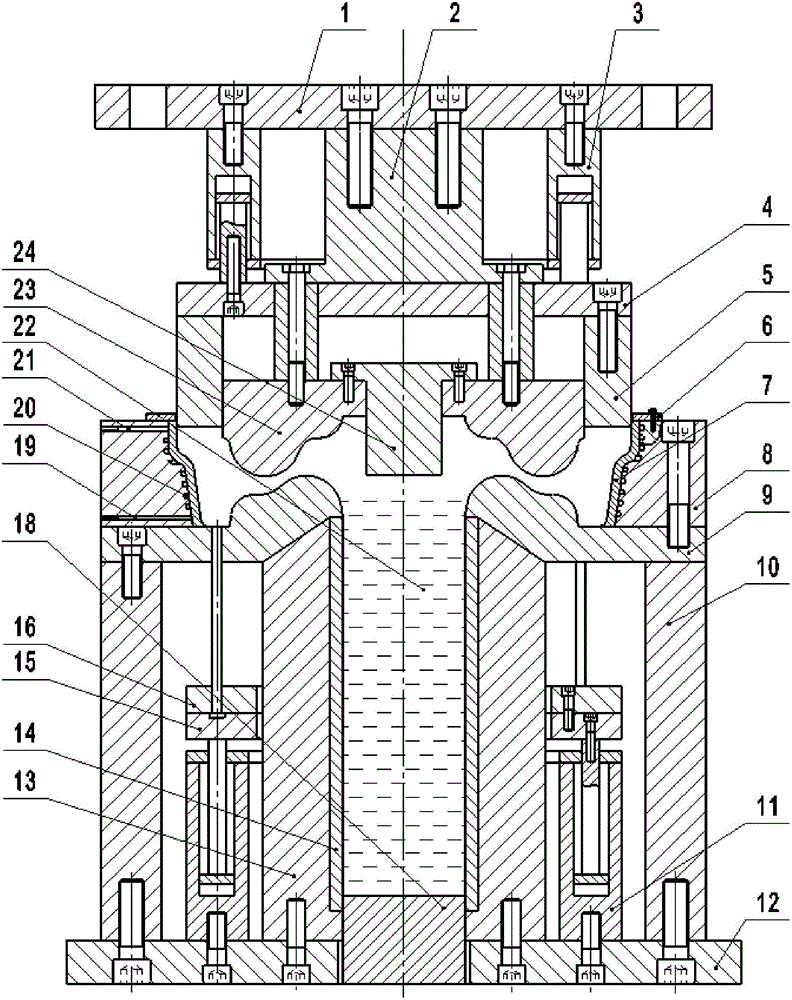

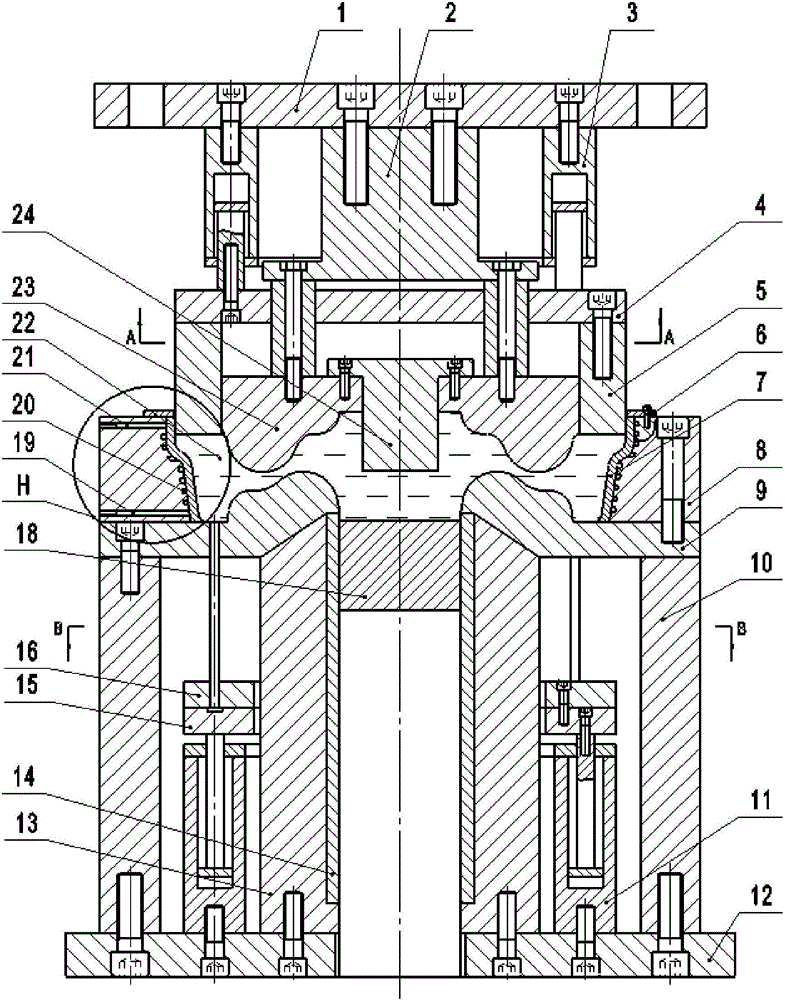

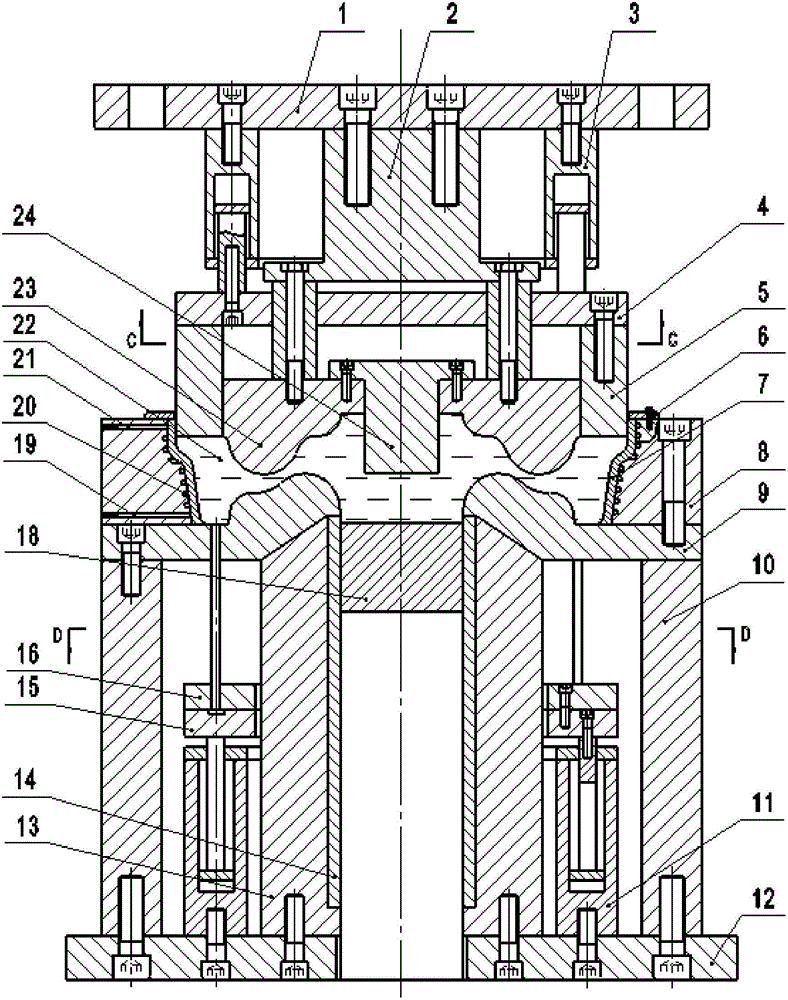

[0056] The present invention will be described in detail below with reference to the accompanying drawings.

[0057] A casting mold of an S-spoke rail wheel blank, such as Figure 1 to Figure 8 As shown, the mold includes a cope and a drag.

[0058] The lower mould includes: lower mould sleeve 8, lower mould bottom 9, lower mould support 10, lower mould fixing plate 12, pressure chamber wall 13, lower pressing head 18 and annular top piece system.

[0059] The end face of the flat end of the pressure chamber wall 13 is located in the center of the upper surface of the lower type fixing plate 12, and one end face of the lower type support 10 is located at the periphery thereof. The pressure chamber wall 13 and the lower type support 10 are coaxially installed on the lower type fixing plate 12. on the upper surface.

[0060] The annular ejector system includes: ejector oil cylinder 11 , push plate 15 , ejector rod pressing plate 16 and eight to sixteen ejector rods.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com