Casting method of conformal sand-covered chill iron

A chilled iron and sand-covered technology, which is applied to casting molding equipment, molds, and mold components, can solve problems such as prolonging the solidification time of castings, and achieve the effects of improving process yield, avoiding porosity defects, and preventing shrinkage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, this embodiment provides a casting method of joint piece, specifically, the casting method of model is joint piece:

[0034] Regional division

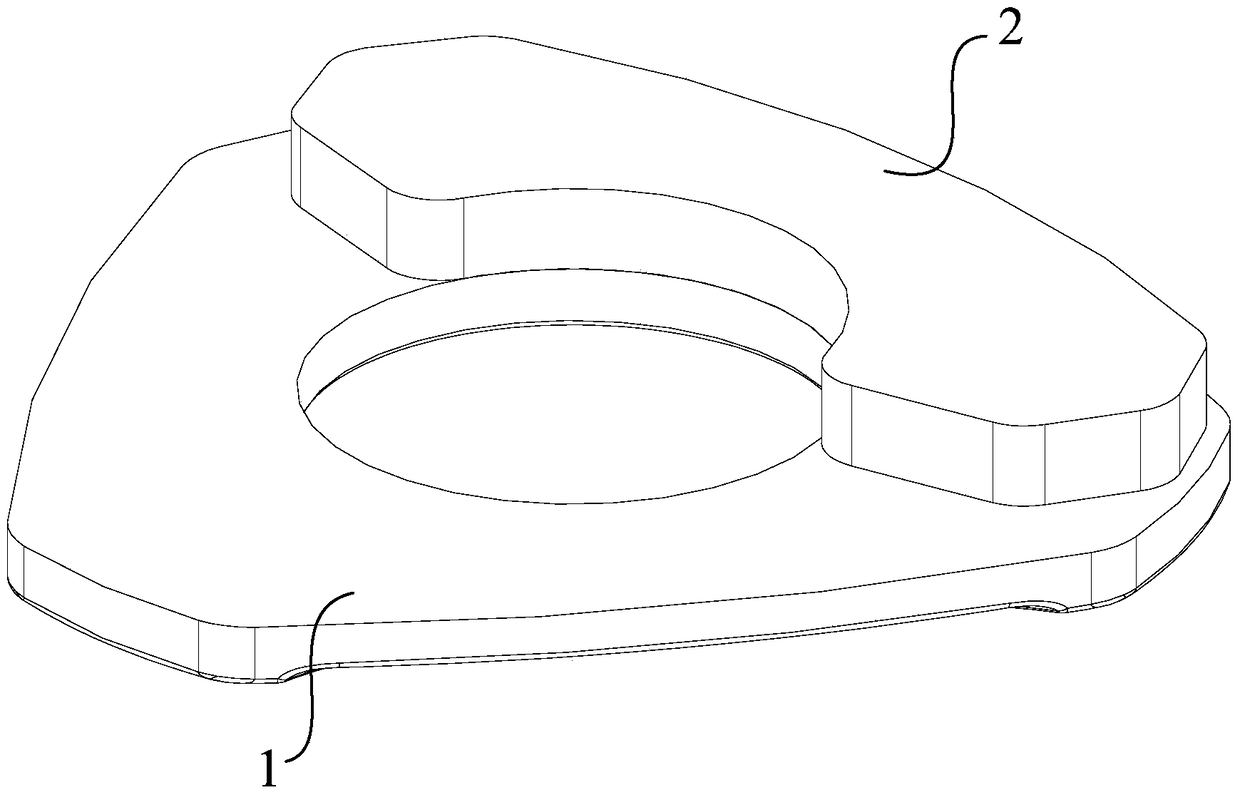

[0035] Such as figure 1 As shown, according to the characteristics of the casting, the casting has 3 hot joints (the determination of the hot joints is a conventional technical means in the art, so in this embodiment, it will not be described in detail), so that the riser is fed against one hot joint, According to the basic modulus method, the feeding range of the riser is calculated. In order to expand the feeding range of the riser, the sand-covered cold iron is designed so that the feeding range of the riser is "riser action area + terminal area + cold iron action area" while covering the entire casting.

[0036] Conformal sand-covered cold iron design.

[0037] Determine the application modulus of the chilled iron action area, that is, the modulus of the casting adjacent to the chilled iron is taken as the ...

Embodiment 2

[0050] Embodiment 2. This embodiment provides a casting method for a differential carrier, specifically, a casting method whose model is a differential carrier:

[0051] Regional division:

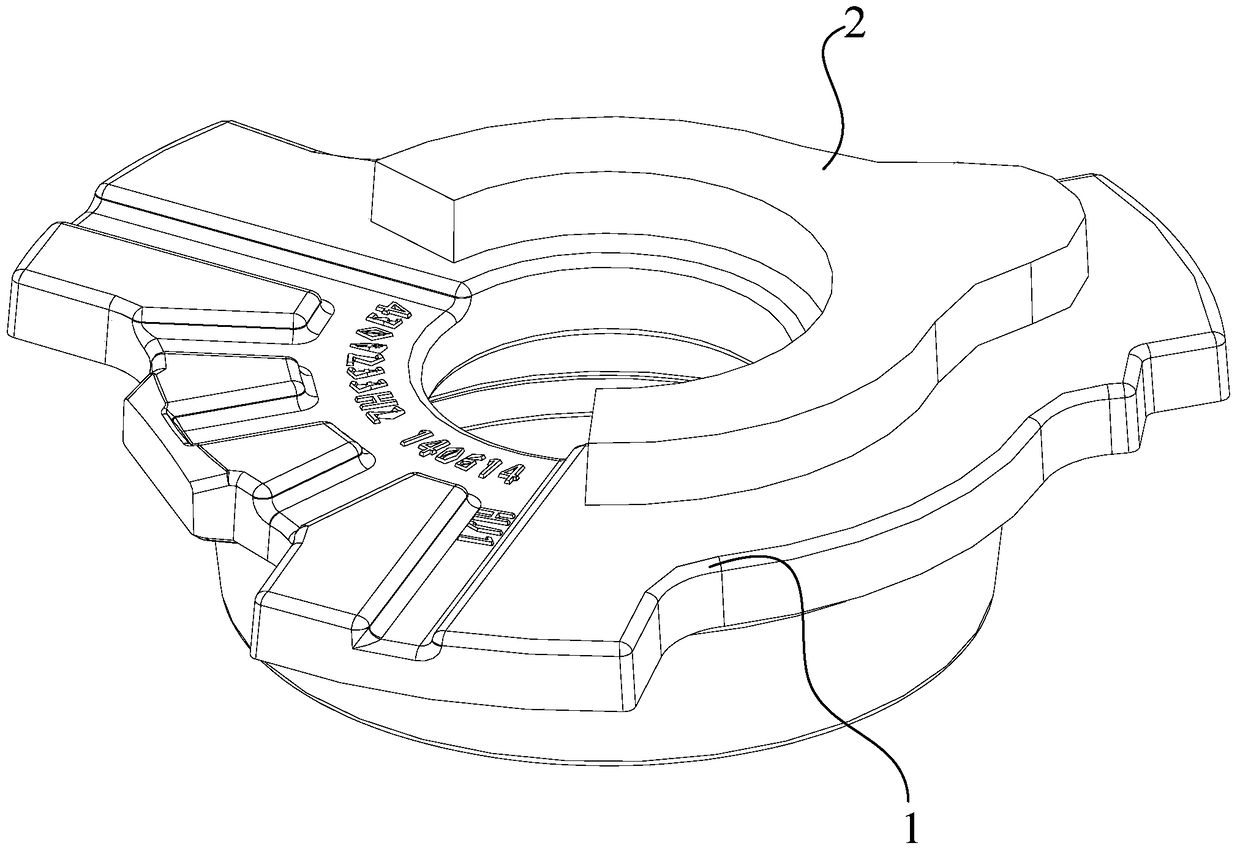

[0052] Such as figure 2 As shown, according to the characteristics of the casting, the casting has 3 hot joints, and the structural shape is similar to that of The feeding range of the riser is calculated by the basic modulus method. In order to expand the feeding range of the riser, the sand-covered cold iron is designed so that the feeding range of the riser is "riser action area + terminal area + cold iron action area". Cover the entire casting.

[0053] Design of Conformal Sand-Coated Chill Iron

[0054] Determines the applied modulus of the chilled iron zone. That is, the modulus of the casting adjacent to the cold iron is taken as the section modulus at the position of the natural end area, and the analysis is 0.87cm; if Mr≤0.87cm, take Mr=0.81cm;

[0055] Determine the thickne...

Embodiment 3

[0065] Embodiment 3, this embodiment provides a casting method for planetary wheel housing casting

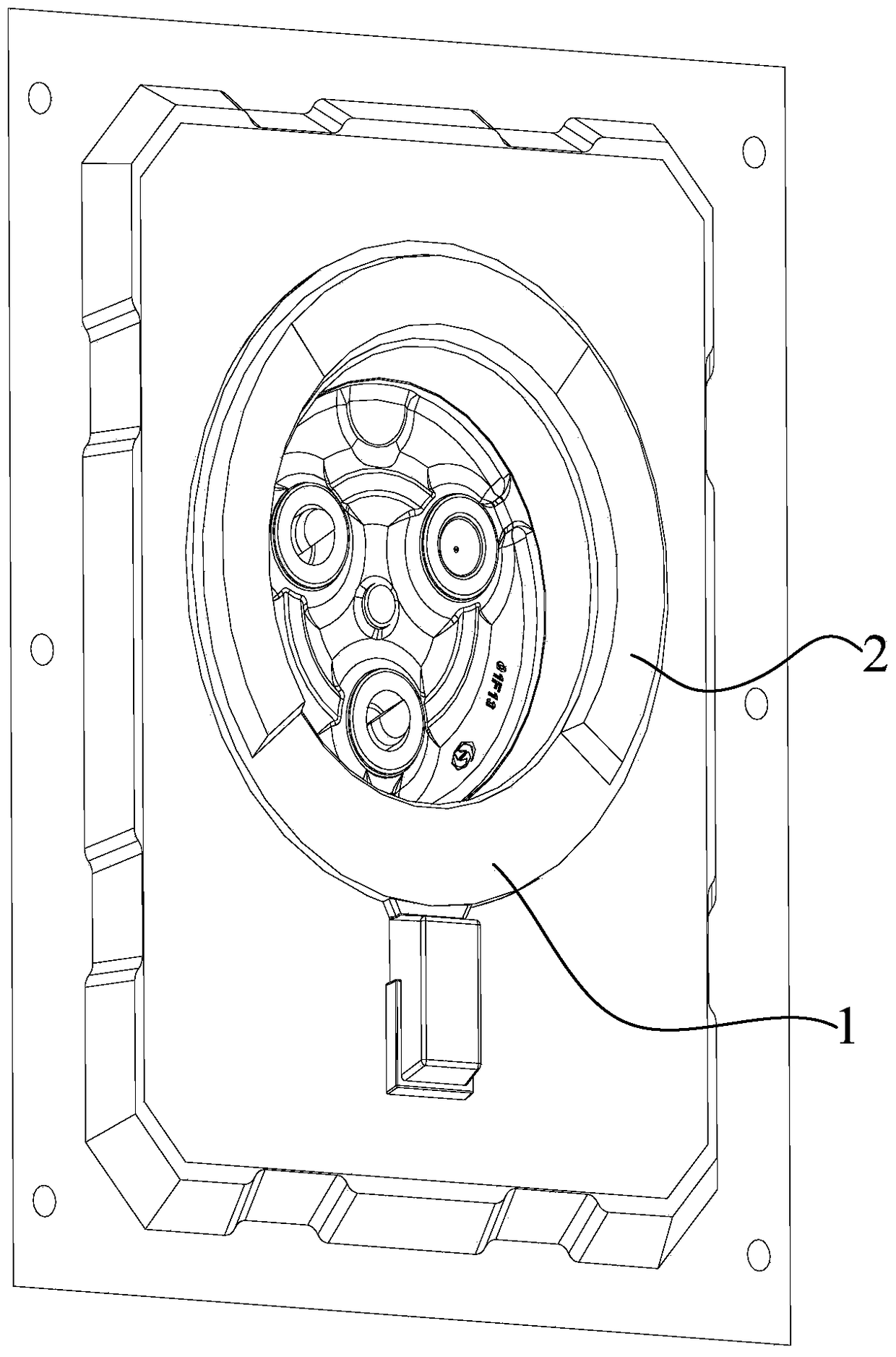

[0066] Such as image 3 As shown, the flange of this casting is well-proportioned in ring shape, and there is no end area after the riser is set on the side of the flange. An artificial end zone can be created using a conformal grit chill. The thickness of the flange is 16mm. According to the relevant casting manual, the feeding distance of the riser is about 127mm. Iron zone.

[0067] Determine the cold iron action area and the length of the cold iron. The circumference of the flange is φ320×3.14=1004.8(mm), and the length of the cold iron action area is 1004.8-308=696.8mm. Since the length of the cold iron is too long, in order to facilitate processing, the cold iron is divided into 3 pieces, each with a length of L =226mm, located in the same core body and evenly distributed.

[0068] Considering that the total length of the cold iron is more than 500mm, it is determine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com