A processing method for thin-walled semi-shell parts

A processing method and half-shell technology, applied in the field of mechanical parts processing, can solve problems such as inability to directly clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

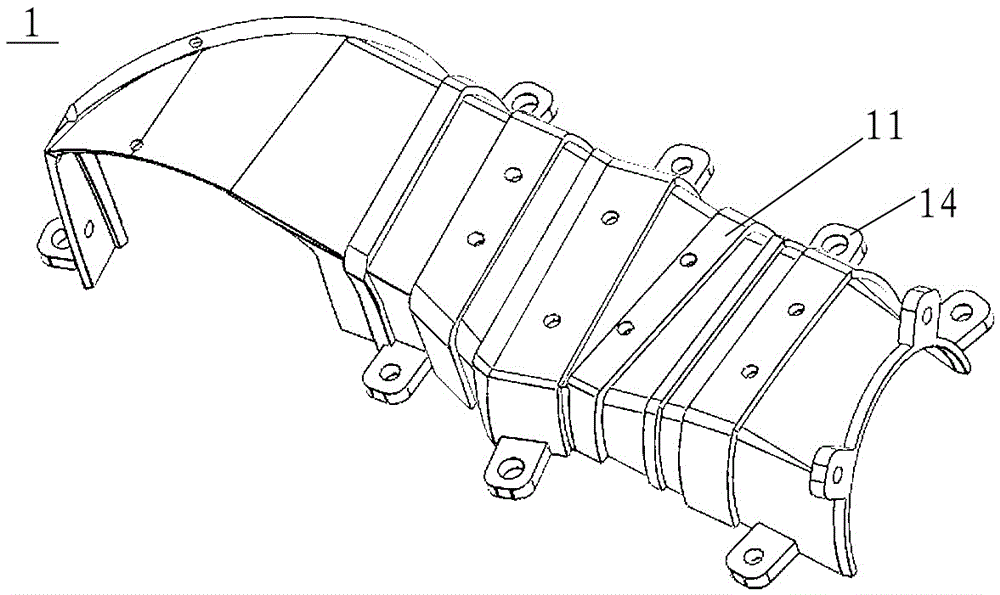

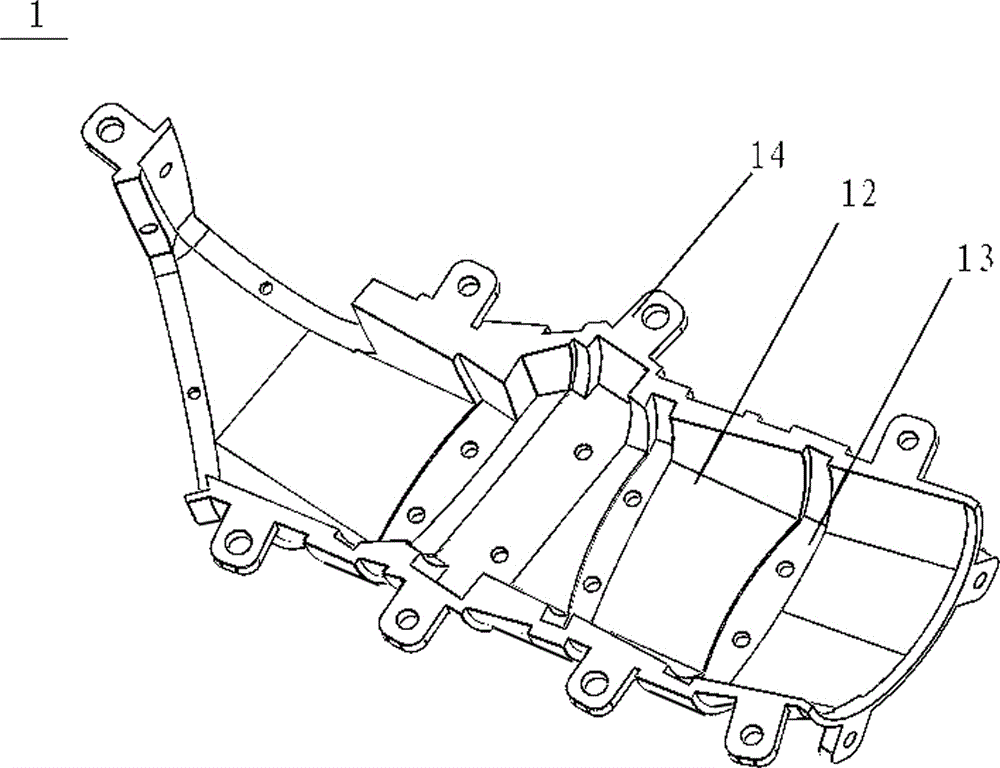

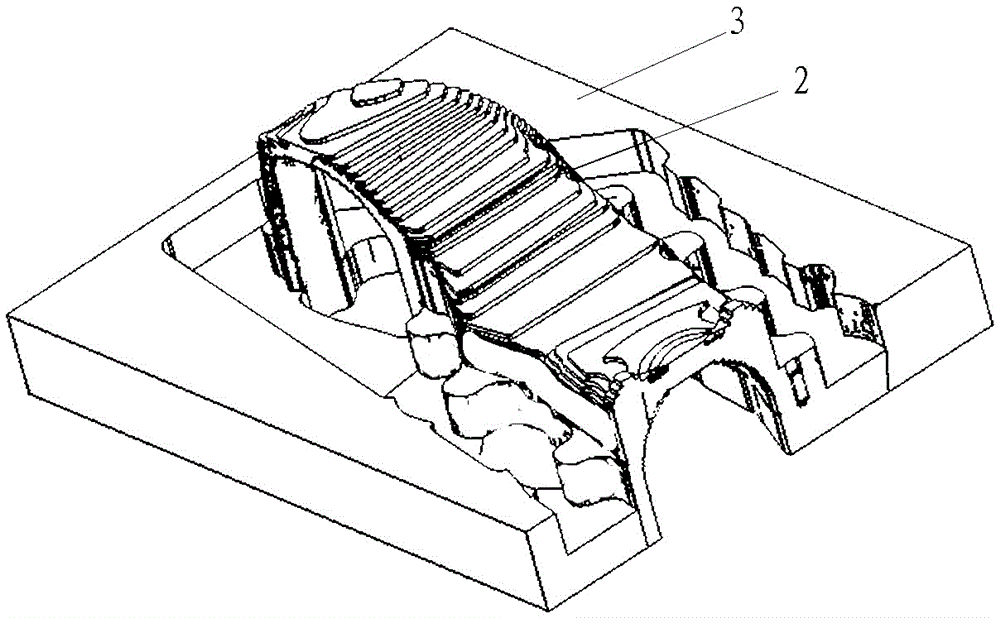

[0037] Embodiment 1 of the processing method of the thin-walled half-shell parts of the present invention: as Figure 1 to Figure 17 shown, including the following steps,

[0038] Step 1, according to the position of the part blank 2 in the plate-shaped base material, the shape of the part blank 2 is roughly machined by a CNC milling machine, and a process handle 3 integrally connected around the part blank 2 is reserved on the plate-shaped base material. 3 is a U-shaped plate body surrounding the part blank, leaving no more than R4 rounded corners at all corners, and milling a pit at the connection between the process handle 3 and the part blank 2, and the pit surrounds the part blank 2; in the part The machining allowance is reserved on the blank 2, so that the convex surface of the blank 2 and the clamping platform are exposed from the upper surface of the process handle 3, and the mounting end surface of the clamping platform on the component blank 2 is raised from the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com