Die-cutting roller limiting block

A technology of limit block and die-cutting roller, which is applied in metal processing and other directions, can solve the problems of left-right movement, low precision, and easy deviation in the left-right direction, so as to ensure the accuracy of die-cutting, prevent deviation and ensure precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

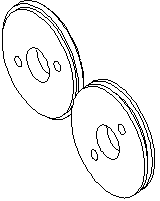

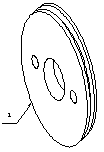

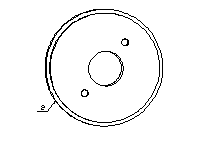

[0017] according to Figure 1-3 , Die-cutting roller limit block, characterized in that it includes concentric concave block 1 and convex block 2, the above two blocks are respectively installed on the operation surface side of the upper and lower die-cutting rollers, and the end faces of concave block 1 and convex block 2 are mutually meshing ( figure 1 ). Concave block and protruding block refer to that the end surface of the circumference is inwardly recessed or outwardly protruding, rather than the center of the circle being inwardly recessed or outwardly protruding. The cross section of the concave block 1 and the convex block 2 is circular, and the center of the concave block 1 and the convex block 2 is provided with a mounting hole ( figure 2 and image 3 ), the concave block 1 and the convex block 2 are fixed on the operating surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap