A non-magnetic vibrating disk alignment machine

A technology of magnetic vibration and discs, which is applied to conveyors, conveyor objects, rotary conveyors, etc., can solve problems such as high maintenance costs, poor working environment, and surface deterioration, and achieve good system stability and casting speed Fast, bottomless suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

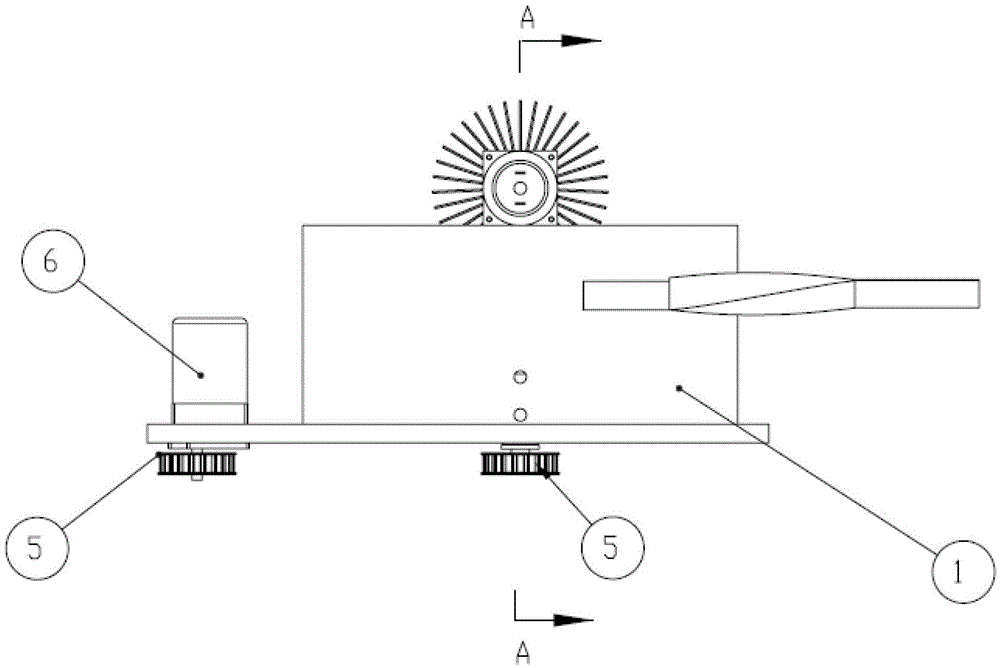

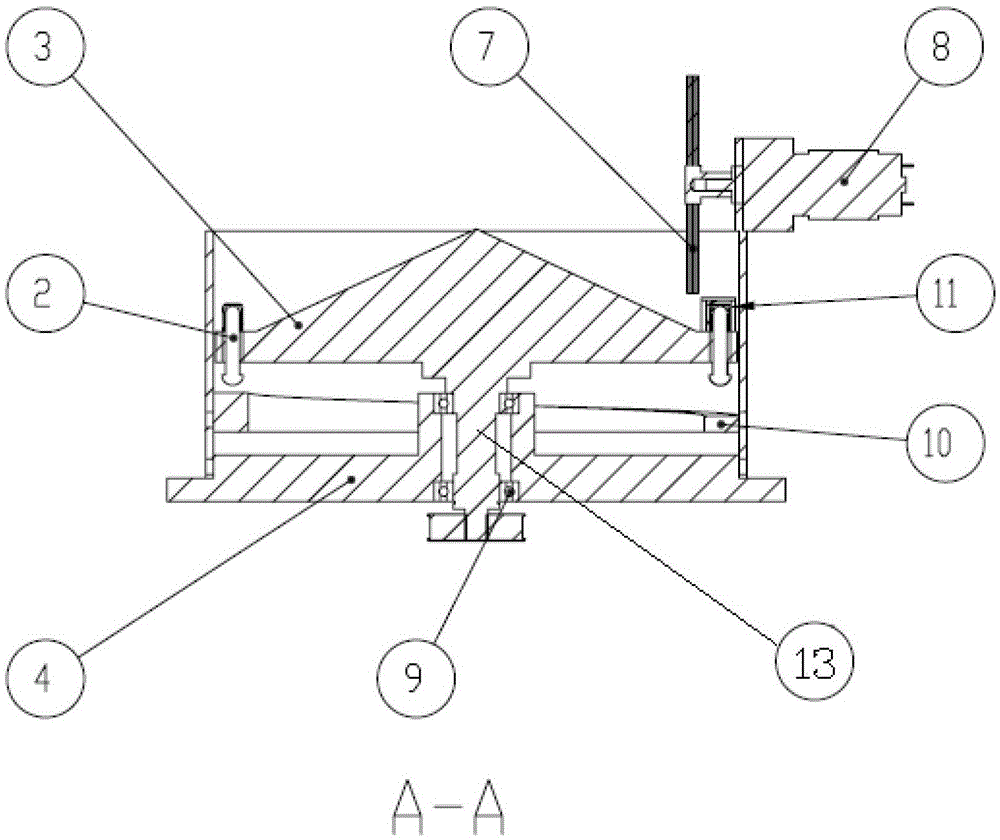

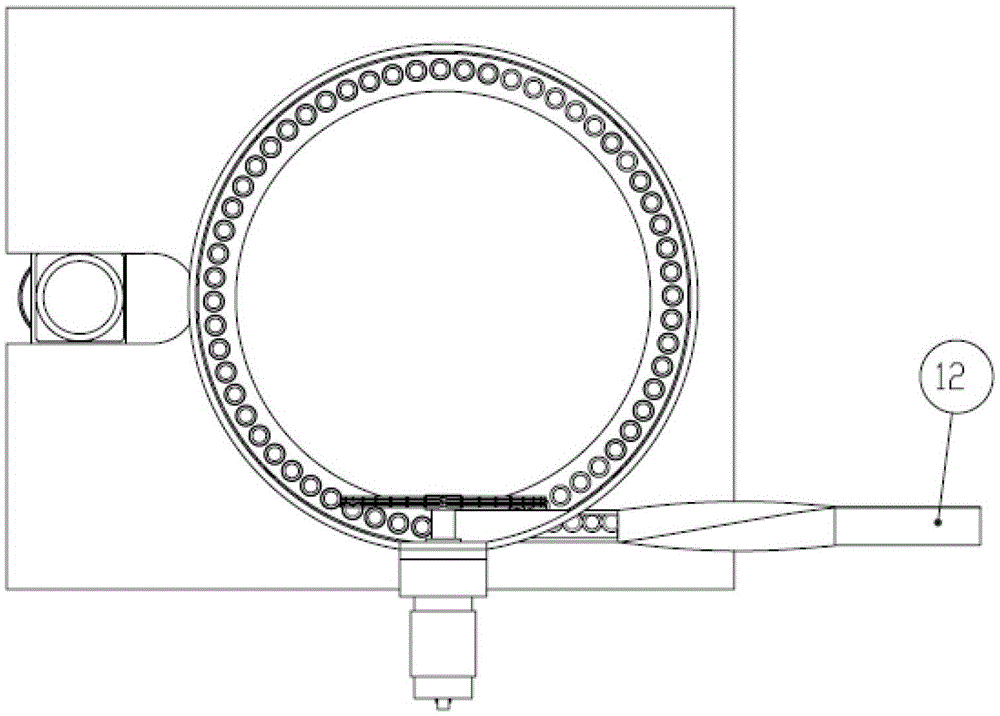

[0018] Such as Figure 1~Figure 3 As shown, a non-magnetic vibrating disk arrangement machine includes a main body shell 1, a bullet head 2, a turntable 3, a base 4, a synchronous wheel 5, a main motor 6, a brush 7, a brush motor 8, a bearing 9, a track disk 10, Plastic cap 11, steering slide 12, rotating spindle 13, the main motor 6 is installed on one side of the base 4, and the main body shell 1 is installed on the other side. The base 4 corresponding to the lower part of the main body shell 1 has a center hole , A rotating spindle 13 is installed in the center hole, a synchronizing wheel 5 is installed and fixed at the lower end of the rotating spindle 13, the turntable 3 is above the rotating spindle 13, and the turntable 3 is conical with the bottom surface on the bottom and the apex on the top. The diameter of the bottom surface is smaller than the main body shell 1. Inner diameter, along the outer circumference of the conical bottom surface of the turntable 3, several b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com