a filling machine

A filling machine and adjustment mechanism technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of reducing work efficiency, unable to adjust the vertical height and horizontal position of the bottle feeding screw, increasing production costs, etc. The effect of labor efficiency, orderly bottle feeding, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

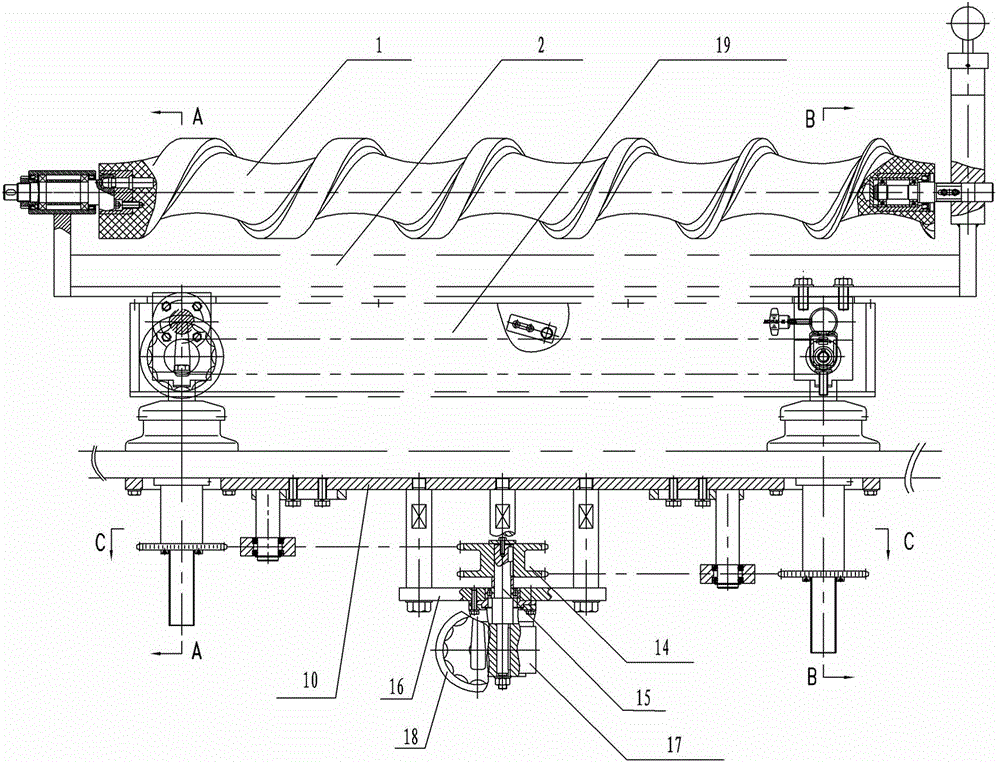

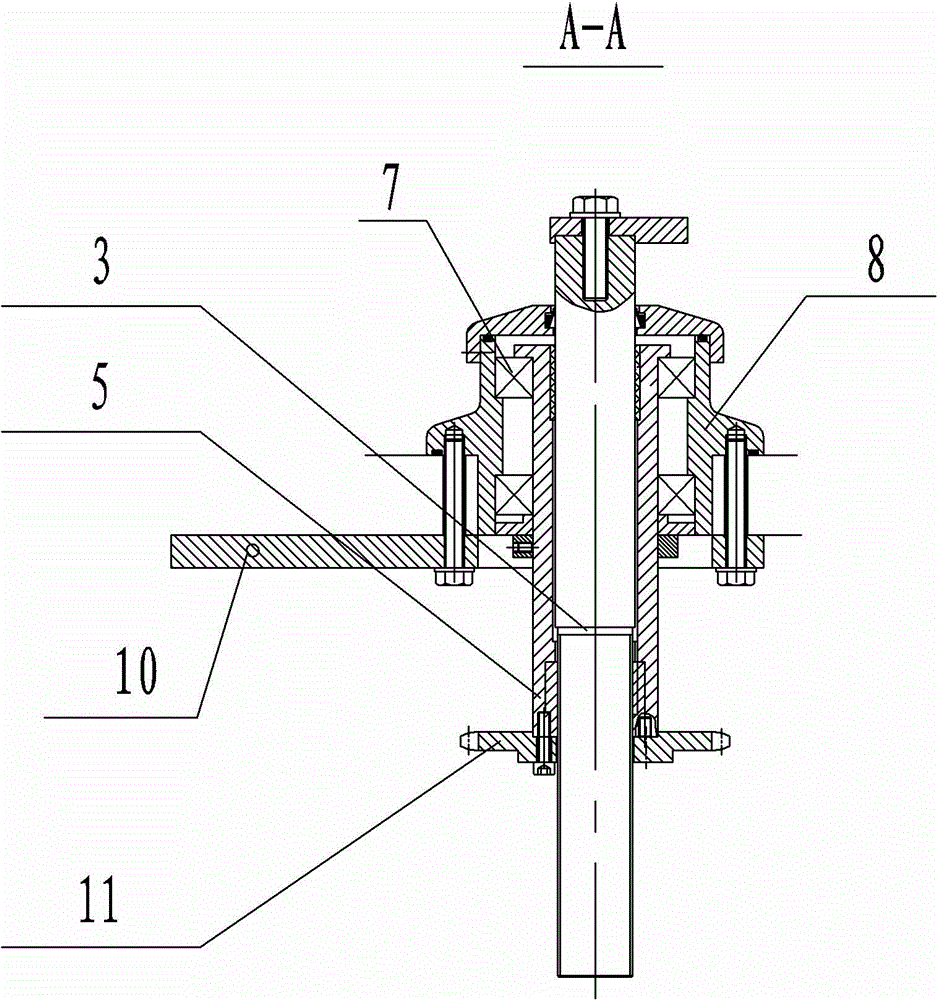

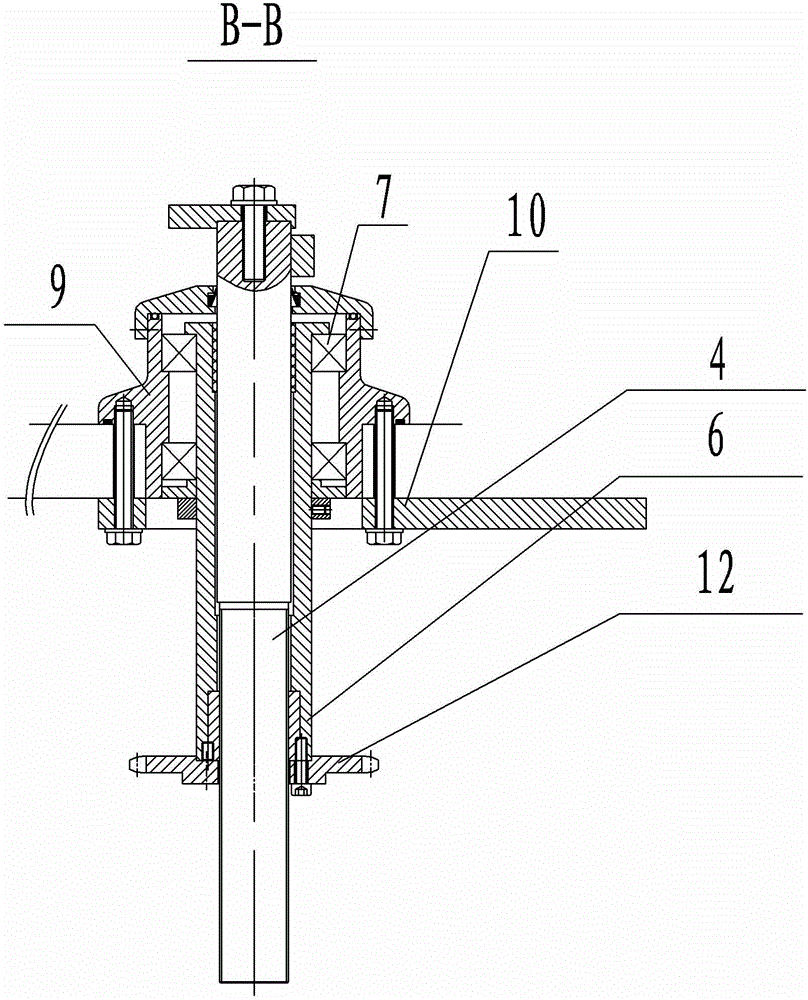

[0011] Embodiment 1: as figure 1 to Figure 4 As shown, a filling machine includes a bottle feeding screw 1, and the bottle feeding screw 1 is installed on a support frame 2, and the support frame 2 is installed on two vertical height adjustment mechanisms through two left and right horizontal position adjustment mechanisms. The vertical height adjustment mechanism includes a left lifting guide rod 3 and a right lifting guide rod 4, a part of the left and right lifting guide rods is threaded, and the left and right lifting guide rods respectively pass through the left sleeve 5 and the right sleeve 6 which are threaded inside. One end of the lifting guide rod is fixed with the horizontal position adjustment mechanism, the left and right sleeves are respectively installed in the left support base 8 and the right support base 9 through the rolling bearing 7, the left and right support bases are fixed on the mounting plate 10, and the transmission mechanism is set on the left an...

Embodiment 2

[0014] Embodiment 2: a kind of filling machine comprises bottle-feeding screw rod 1, and bottle-feeding screw rod 1 is installed on the support frame 2, and support frame 2 is installed on two vertical height adjustment mechanisms by horizontal position adjustment mechanism 19, and described vertical The vertical height adjustment mechanism includes a left lifting guide rod 3 and a right lifting guide rod 4, a part of the left and right lifting guide rods is threaded, and the left and right lifting guide rods pass through the left sleeve 5 and the right sleeve 6 respectively, and one end of the left and right lifting guide rods is connected with the horizontal The position adjustment mechanism 19 is fixed, the left and right sleeves are respectively fixed in the left support base 8 and the right support base 9 through screw connection, the left and right support bases are fixed on the mounting plate 10, and the transmission mechanism is set on the left and right lifting guide ro...

Embodiment 3

[0016] Embodiment 3: a kind of filling machine comprises bottle-feeding screw rod 1, and bottle-feeding screw rod 1 is installed on the support frame 2, and support frame 2 is installed on two vertical height adjustment mechanisms by horizontal position adjustment mechanism 19, and described vertical The vertical height adjustment mechanism includes the left lifting guide rod 3 and the right lifting guide rod 4, the left and right lifting guide rods pass through the left sleeve and the right sleeve respectively, one end of the left and right lifting guide rods is fixed with the horizontal position adjustment mechanism 19, and the left and right sleeves pass through the screw They are respectively installed in the left support base 8 and the right support base 9, the left and right support bases are fixed on the mounting plate 10, and the transmission mechanism is set on the left and right lifting guide rods. The transmission mechanism includes a connecting plate, the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com