Phenol-degrading bacteria and method for preparing indigo by conversing indole

A phenol-degrading bacteria and phenol-degrading technology, applied in the field of bioengineering, can solve the problems of ignoring advantages, limited research, and single enzyme resources, and achieve the effects of simple extraction steps, high product concentration, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

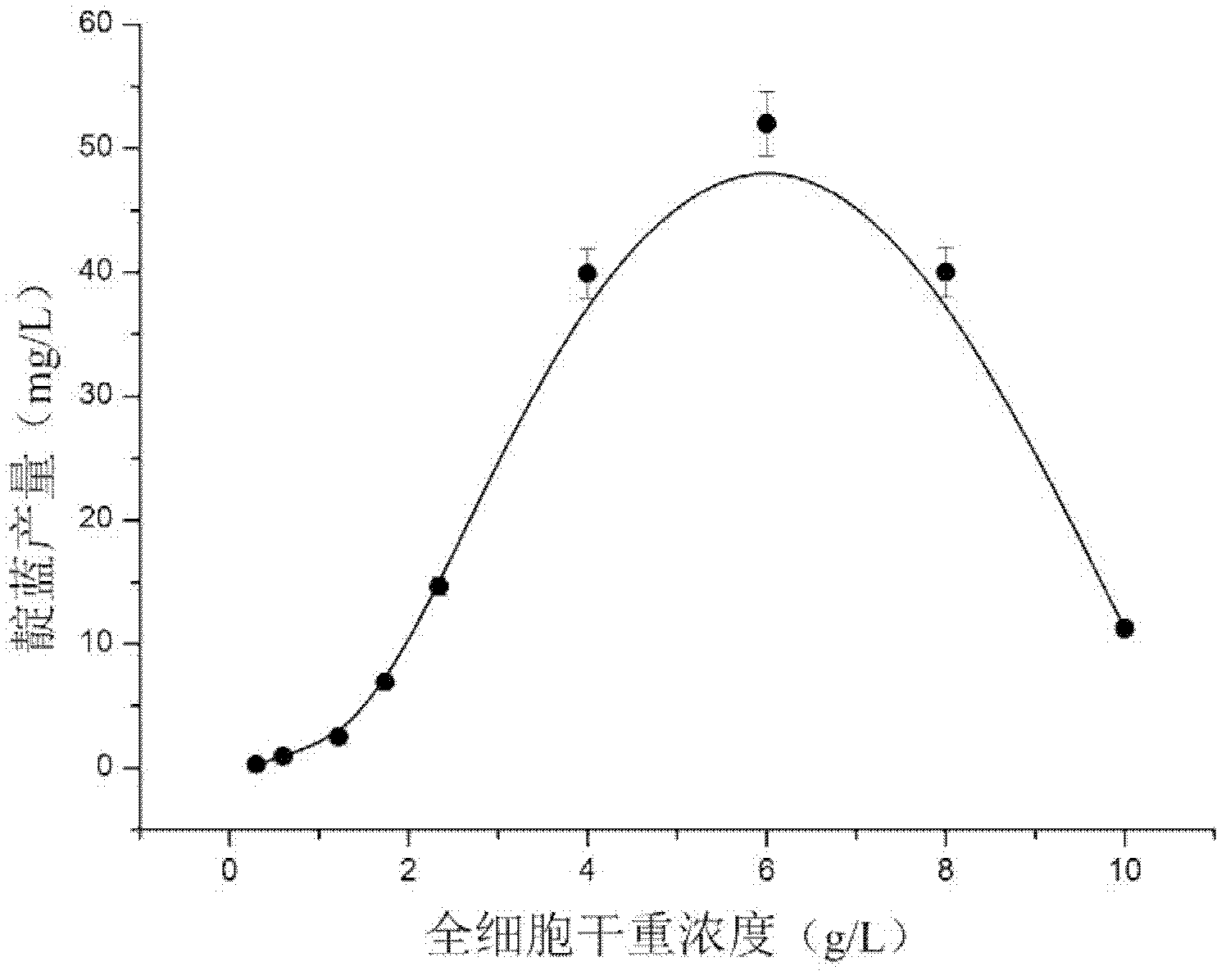

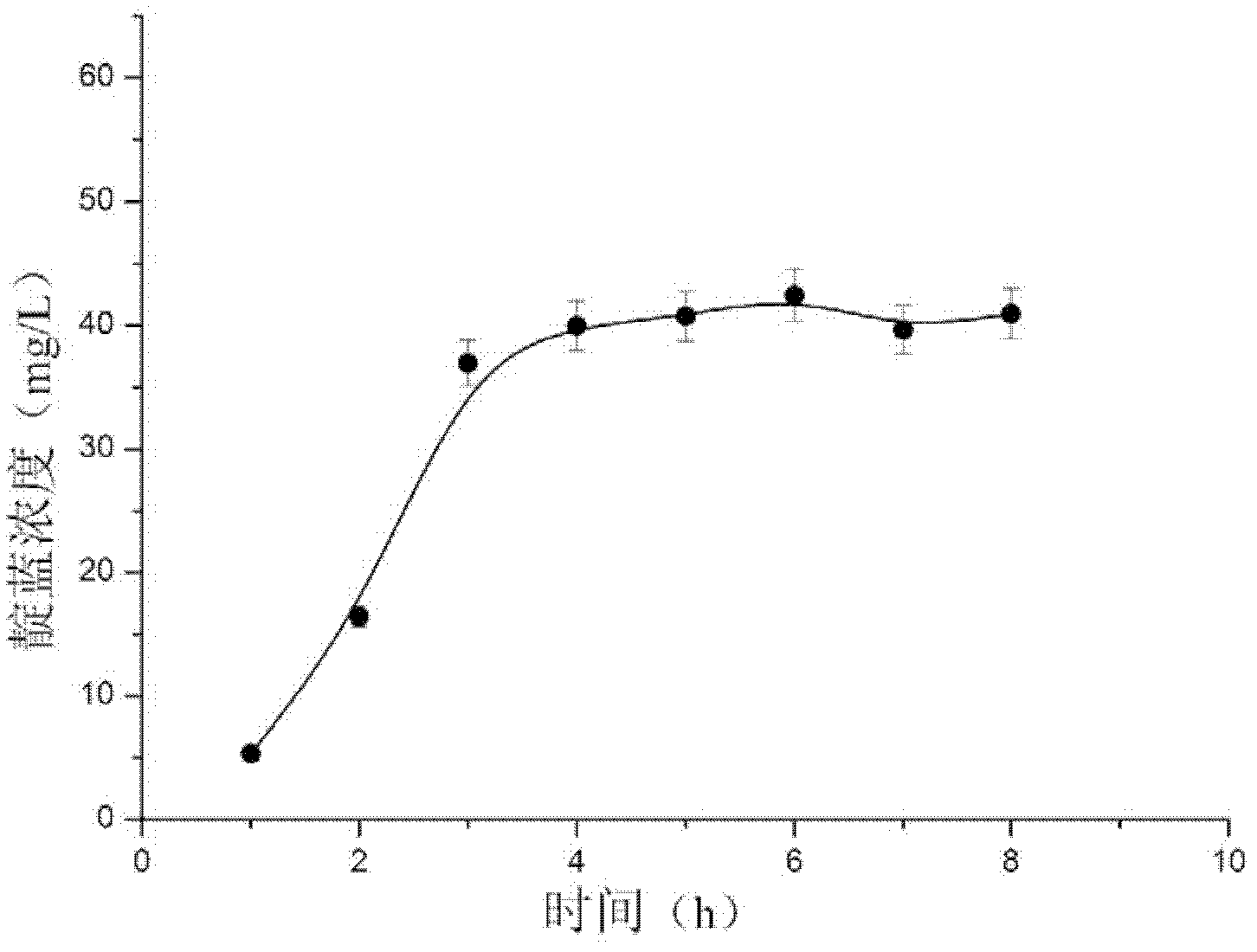

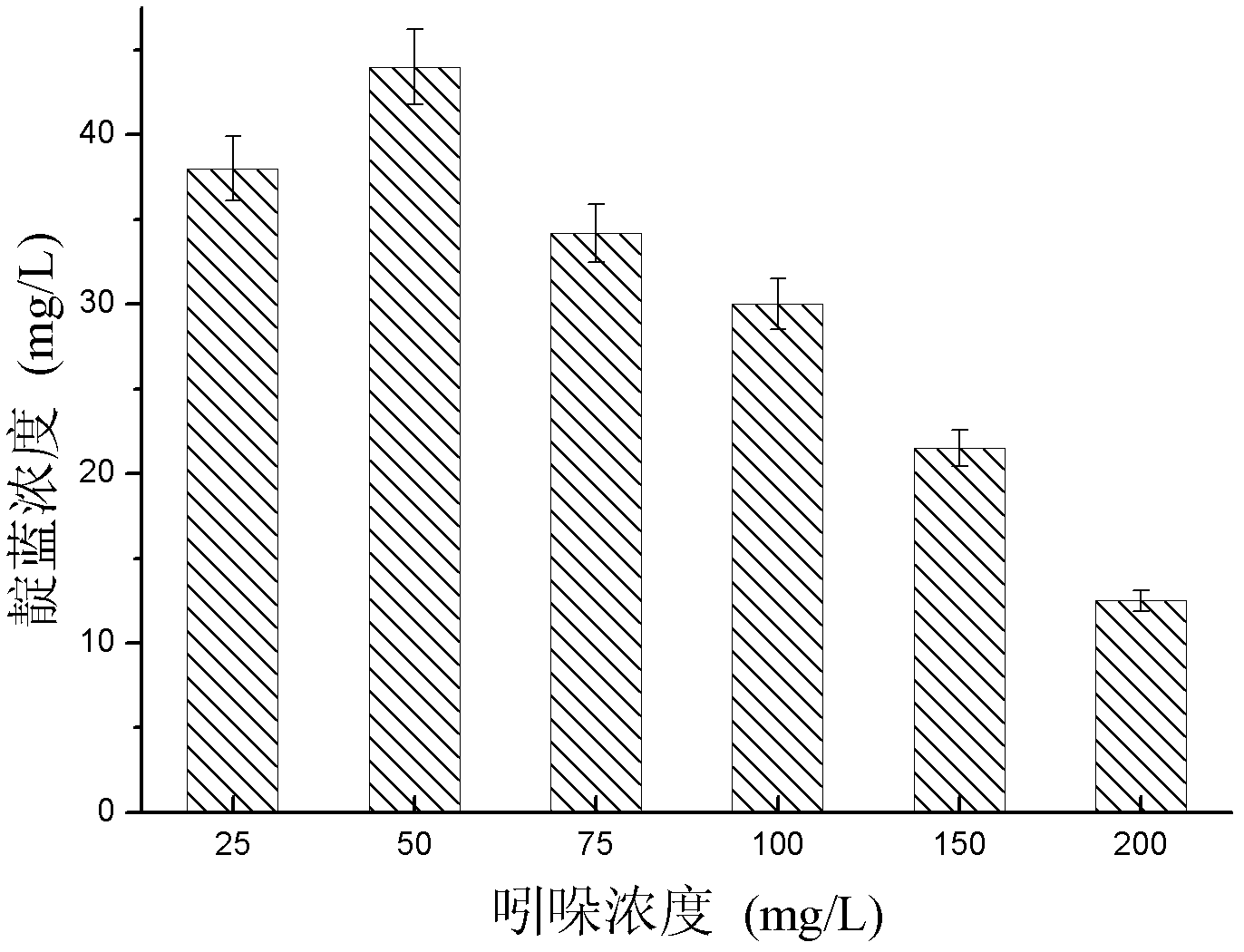

[0024] Example 1, using the phenol-degrading bacteria Pseudomonas monteilii QM to biotransform indole to produce indigo, and investigate the influence of some parameters on the concentration of indigo.

[0025] The steps and parameters for the expanded cultivation and biotransformation of indole to produce indigo by the phenol-degrading bacteria Pseudomonas monteilii QM are as follows:

[0026] 1. Inoculate the phenol-degrading bacteria Pseudomonas monteilii QM strain on a solid plate LB medium (yeast powder 5g / L, peptone 10g / L, NaCl 5g / L, agar 15-20g / L, adjust the pH to 7.0-7.2), Cultivate statically at 37°C for 2 days, store in refrigerator at 4°C, and serve as activated seeds on the plate;

[0027] 2, use the plate activation seed of step 1 gained, be inoculated in the liquid M9 substratum (Na 2 HPO 4 12H 2 O 17.1g / L, KH 2 PO 4 3.0g / L, NH 4 Cl 1.0g / L, NaCl 0.5g / L, FeCl 3 0.00075g / L, 1g / L glucose, 2mmol / L MgSO4), shaking culture at 20-40°C, 50-300r / min for 12-16 hou...

Embodiment 2

[0035] Example 2, phenol-degrading bacteria Pseudomonas monteilii QM biotransforms indole to produce indigo.

[0036] Steps 1-4 are the same as in Example 1, and the dry weight concentration of the expanded cultured Pseudomonas monteilii QM bacteria obtained in step 3 is controlled to be 4.0 g / L.

[0037] In a 50mL Erlenmeyer flask, add 20mL of the expanded cultured Pseudomonas monteilii QM bacteria prepared in step 3, and 15 μL of the indole / acetone solution prepared in step 4, so that the concentration of indole in the reaction solution is 75 mg / L. , 300r / min shaking for 6 hours.

[0038] According to the measurement method described in Example 1, the indigo concentration recorded is 35.24 mg / L.

Embodiment 3

[0039] Example 3, phenol-degrading bacteria Pseudomonas monteilii QM biotransforms indole to produce indigo.

[0040] Steps 1-4 are the same as in Example 1, and the dry weight concentration of the expanded cultured Pseudomonas monteilii QM bacteria obtained in step 3 is controlled to be 8.0 g / L.

[0041] In a 50mL Erlenmeyer flask, add 20mL of the enlarged cultured Pseudomonas monteilii QM bacteria prepared in step 3, 20 μL of the indole / acetone solution prepared in step 4, so that the concentration of indole in the reaction solution is 100mg / L, at 40°C , 250r / min shaking reaction for 8 hours.

[0042] According to the measurement method described in Example 1, the indigo concentration recorded is 31.20 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com