Stress application system for large-tonnage static load tests

A static load test, large tonnage technology, applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of low bearing capacity, poor stability, unsafe operation, etc. Shear stress capability, effect of increasing maximum normal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

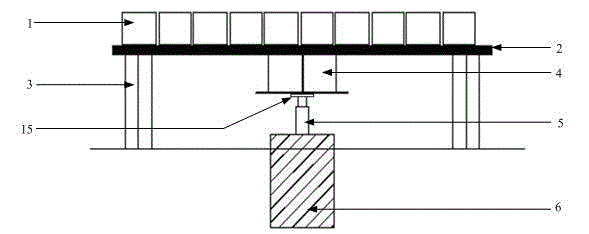

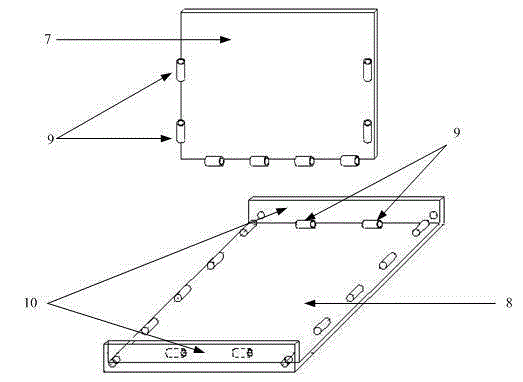

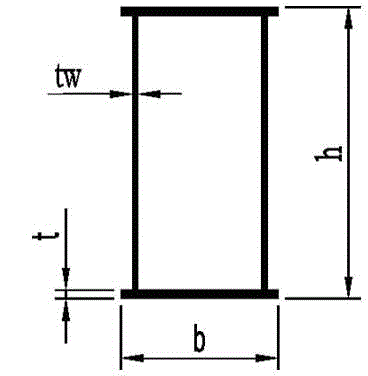

[0030] A large-tonnage static load test force system, comprising a box girder 4 and a counterweight box 1, characterized in that a reinforcing plate 15 is fixed in the middle of the lower plane of the box girder 4.

[0031] In the static load test, as attached figure 1 As shown, the supporting column 3 supporting the shaped steel beam is installed around the tested pile, the counterweight box 1 is placed on the shaped steel beam 2, and the box girder 4 is placed under the shaped steel beam, relying on 5 pairs of jacks placed on the pile head of the test pile Add force to the middle of the box girder, gradually jacking up the box girder, shaped steel girder and counterweight box, thereby applying force to the pile head of the tested pile 6.

[0032] The function of the combined box girder is to transfer the heap load of the counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com