High-depth winze shaft blocking state observation monitoring method

A monitoring method and technology of sliding wells, which are used in wellbore/well components, measurement, earth-moving drilling and mining, etc., can solve the problems of inability to protect the personal safety of operators, affecting mine production, and blocking the connection between the sliding well and the contact road, etc. Achieve the effect of avoiding personal injury accidents and eliminating hidden dangers in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

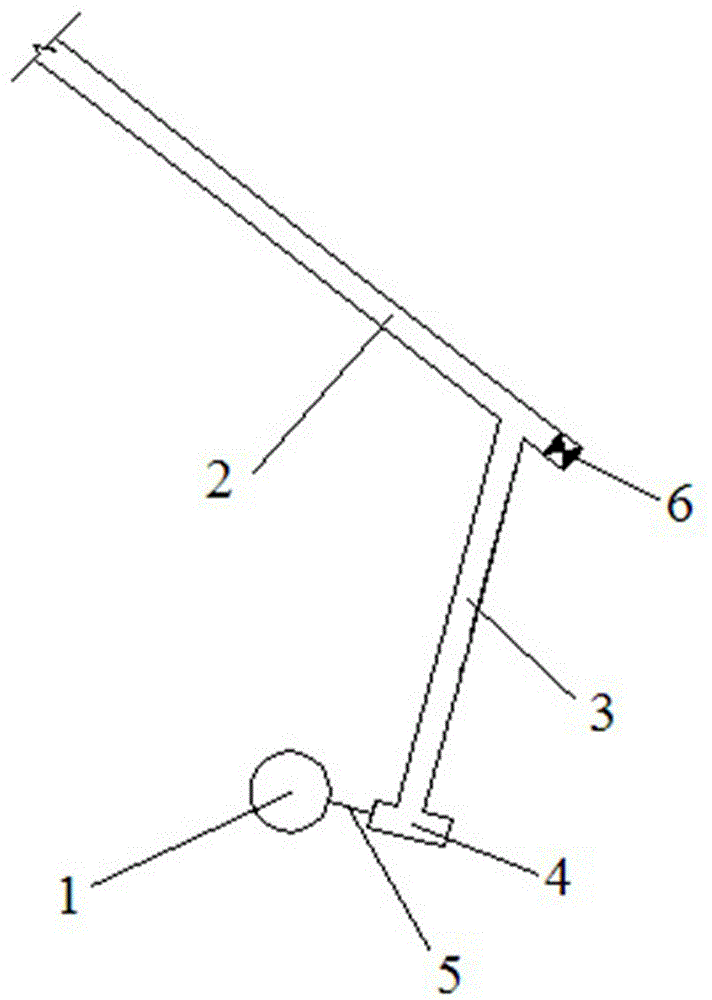

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

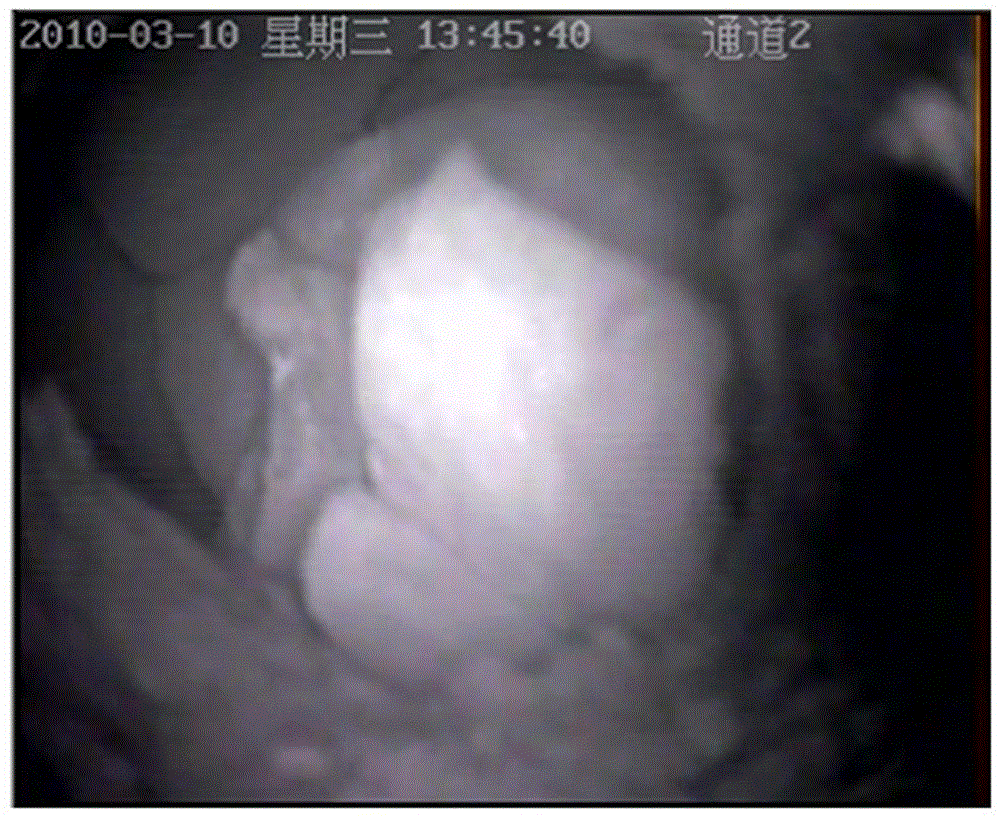

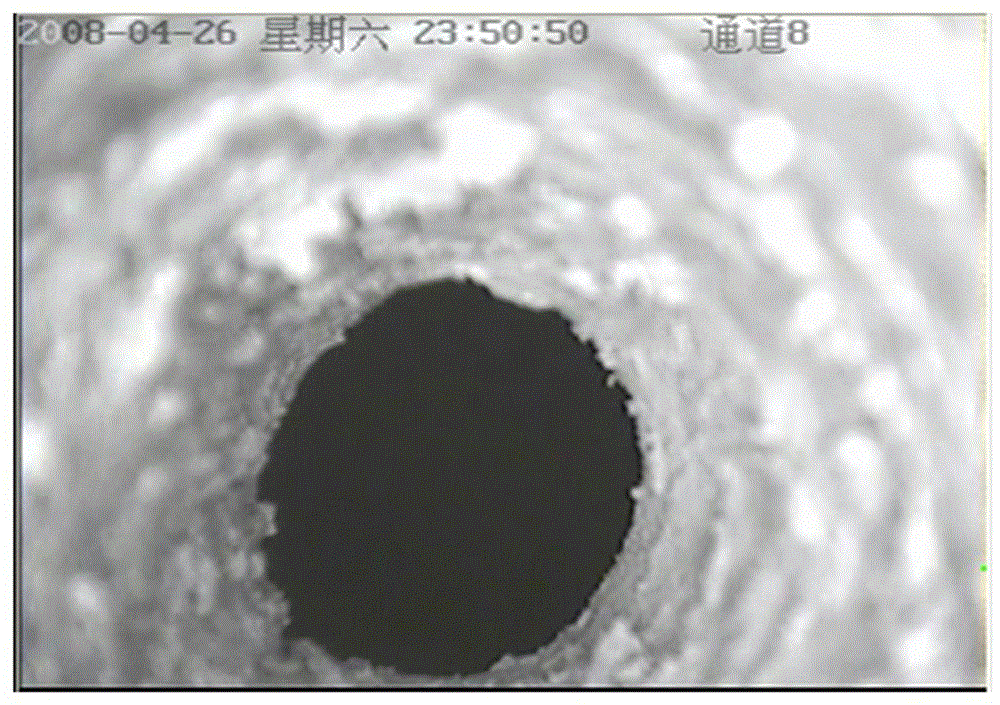

[0022] In the process of mine mining, high-deep chute is usually used to transport the mined raw ore, which has the advantages of less investment, less equipment, low cost and large production capacity. pose a great threat to personal safety. In order to find out the reasons of chute clogging and landslide and fundamentally eliminate production hidden dangers, it is necessary to observe and analyze the chute wellbore in order to formulate a scientific and reasonable chute maintenance plan.

[0023] In general, the blockage of the high-deep chute is observed through the connection roadway, but due to the side pressure when the ore flows in the high-deep chute shaft during the ore-drawing process of the high-deep chute, the connection between the chute and the connection roadway is basically blocked, and it needs to be cleared observations can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com