A method for simultaneous extraction and utilization of coalbed methane and accumulated water in goafs

A technology for coalbed methane and goaf, which is applied in the fields of mining fluids, mining equipment, earth-moving drilling, etc., can solve problems such as lack of effective technological means, achieve economic benefits, eliminate hidden dangers of mine production, and eliminate hidden dangers of water penetration accidents in mining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

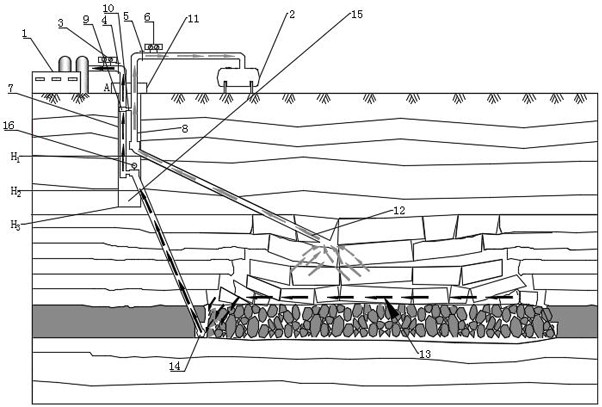

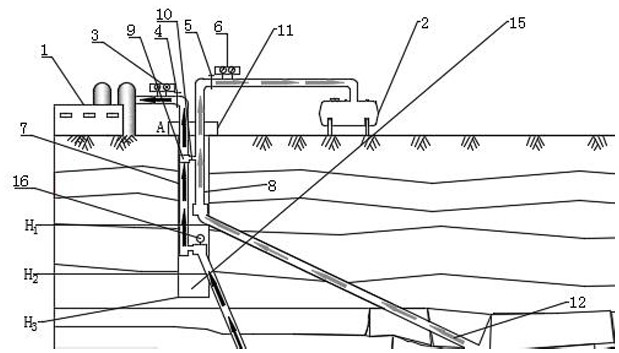

[0019] refer to figure 1 and figure 2 It can be seen that a method for simultaneous extraction and utilization of coalbed methane and accumulated water in a goaf comprises the following steps: S1. Determine the final hole position of the coalbed gas extraction borehole, the final hole position of the pumping well borehole and the drilling construction of the vertical shaft The location of the starting point; according to the design specification of the original working face of the area where the goaf is located and the plan of the excavation project, the upper and lower comparisons of the wells in the goaf are carried out to determine the boundary of the goaf. Judging the height and range of the broken zone, fissure zone, and buckling subsidence zone in the goaf according to the map and mine geological profile, and the position of the final hole of the coalbed methane extraction borehole is selected to be 30 to 50 meters away from the boundary in the goaf In the fissure zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com