Preparation method for mullite by using white mud or fly ash and prepared mullite

A technology of mullite and fly ash, which is applied in the field of making mullite from white mud or fly ash and the prepared mullite, which can solve the problems of increasing energy consumption, introducing impurities, and many preparation steps, so as to save The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

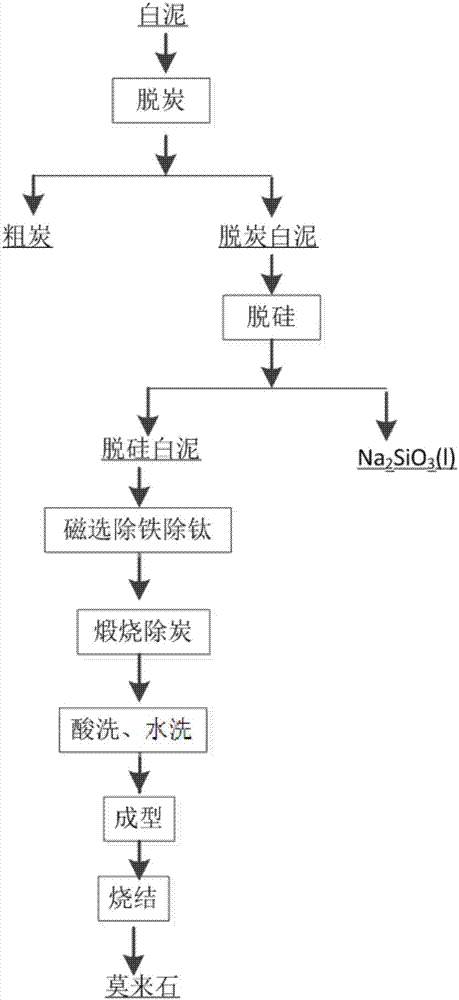

Method used

Image

Examples

preparation example 1

[0050] For the fly ash from Shenhua Zhunzi Company, the composition analysis results obtained by the full chemical analysis method are shown in Table 1.

[0051] Table 1

[0052]

[0053] The fly ash is subjected to the acid method to extract aluminum, specifically, the hydrochloric acid solution with a mass content of 28% and the fly ash are reacted for 1 hour at a liquid-solid ratio of 4:1, and after the reaction is completed, filter, wash, and dry to obtain alumina. The solid residue obtained is lime mud.

[0054] The obtained lime mud (remaining residue) is analyzed through the total chemical analysis method, and the composition analysis results are shown in Table 2,

[0055] Table 2

[0056]

[0057] T Fe 2 o 3 Indicates a mixture of oxides of ferric and ferric iron.

Embodiment 1

[0059] This example illustrates the method for producing mullite from white clay of the present invention.

[0060] The lime mud that 1kg preparation example 1 obtains is put into SF flotation machine (Hongxing Mining Machinery Co., Ltd.), and contains diesel oil and sodium carbonate solution (diesel content is 0.4% by weight, sodium carbonate content is 0.3% by weight) phase with 5kg Contact and carry out flotation decarbonization to obtain decarbonized white mud; then decarbonized white mud and sodium hydroxide solution (concentration is 60g / L) according to the weight ratio (liquid-solid ratio) of sodium hydroxide solution and decarbonized white mud: 4:1 desiliconization at a desiliconization temperature of 90°C for 30 minutes to obtain desiliconized white mud; then put the desiliconized white mud into a superconducting magnetic separator to remove Fe and magnetic induction successively at a magnetic induction of 3T Remove Ti at 5T to obtain demagnetized white mud; then put ...

Embodiment 2

[0067] This example illustrates the method for producing mullite from white clay of the present invention.

[0068] The lime mud that 1kg preparation example 1 obtains is put into the SF flotation machine, and the solution (the kerosene content is 0.2% by weight, and the waterglass content is 0.5% by weight) that contains kerosene and water glass with 4kg is contacted and carries out flotation decarbonization, Obtain decarbonized white mud; then decarbonized white mud and sodium hydroxide solution (concentration is 40g / L) according to the weight ratio (liquid-solid ratio) of sodium hydroxide solution and decarbonized white mud is 3:1 at the desiliconization temperature Carry out desiliconization at 95°C for 40 minutes to obtain desiliconized white mud; then put the desiliconized white mud into a superconducting magnetic separator, remove Fe at a magnetic induction of 2T and remove Ti at a magnetic induction of 4T to obtain Demagnetized white mud; then put the demagnetized whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com