Remote explosion-proof hydrogen production device for recycling coalified carbon dioxide and technology thereof

A remote explosion-proof and carbon dioxide technology, applied in the field of hydrogen production, can solve problems affecting the purity of the synthesizer, increase the consumption of coal raw materials, and environmental pollution, and achieve the effects of simple structure, increased added value, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

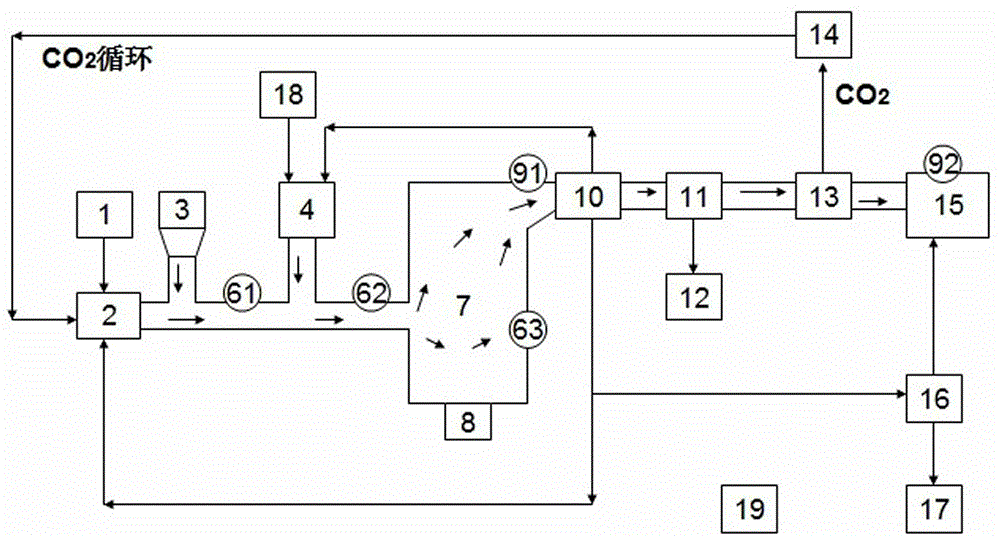

[0035] Embodiment 1: as figure 1 As shown, the remote explosion-proof coalification carbon dioxide recycling hydrogen production device includes: backup power supply 1, CO 2 Tank 14, multi-plasma torch generator 2, intelligent coal feeder 3, solar steam generator 18, steam tank 4, reaction chamber 7, steam generator set 10, purifier 11, separator 13, solar electrolyzer 16, H 2 Tank 15, O 2 Tank 17, on-line detector I61, on-line detector II62, on-line detector III63, remote anti-riot device I91, remote anti-riot device II92, remote explosion-proof master control system 19; the backup power supply 1, CO 2 The tank 14, the steam generator set 10 are connected with the multi-plasma torch generator 2, the solar steam generator 18 is connected with the steam tank 4, the intelligent coal feeder 3, the steam tank 4 and the multi-plasma torch generator 2 are connected to the reaction chamber 7 through a unique pipeline The bottom of the reaction chamber 7 is provided with a cinder ou...

Embodiment 2

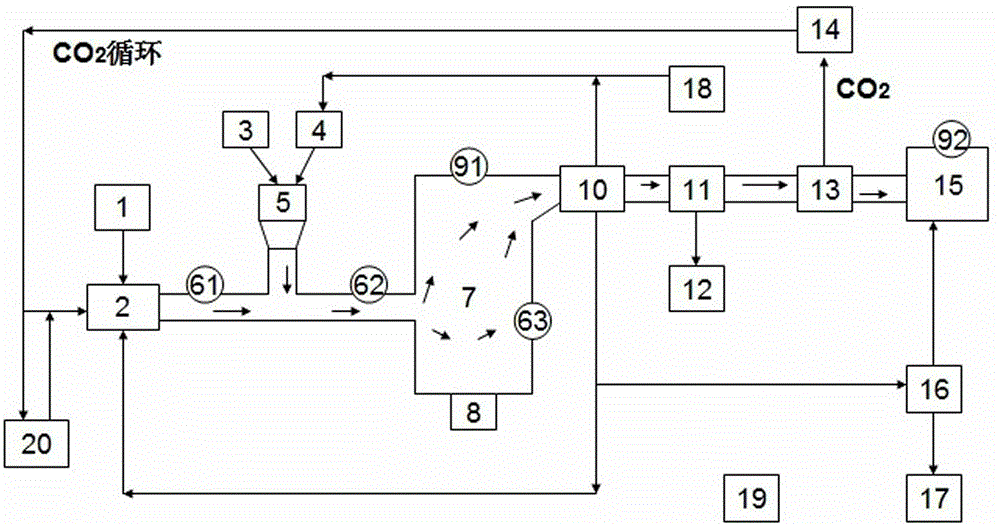

[0069] Embodiment 2: as figure 2 As shown, the remote explosion-proof coalification carbon dioxide recycling hydrogen production device includes: backup power supply 1, CO 2 Tank 14, multi-plasma torch generator 2, intelligent coal feeder 3, solar steam generator 18, steam tank 4, steam coal slurry spraying machine 5, reaction chamber 7, steam generator set 10, purifier 11, separator 13 , Solar electrolyzer 16, H 2 Tank 15, O 2 Tank 17, on-line detector I61, on-line detector II62, on-line detector III63, remote anti-riot device I91, remote anti-riot device II92, remote explosion-proof master control system 19; the backup power supply 1, CO 2 The tank 14, the steam generator set 10 are connected with the multi-plasma torch generator 2, the solar steam generator 18 is connected with the steam tank 4, the intelligent coal feeder 3, the steam tank 4 are connected with the steam coal slurry shotcrete machine 5, and the multi-plasma torch generates The device 2 and the steam coa...

Embodiment 3

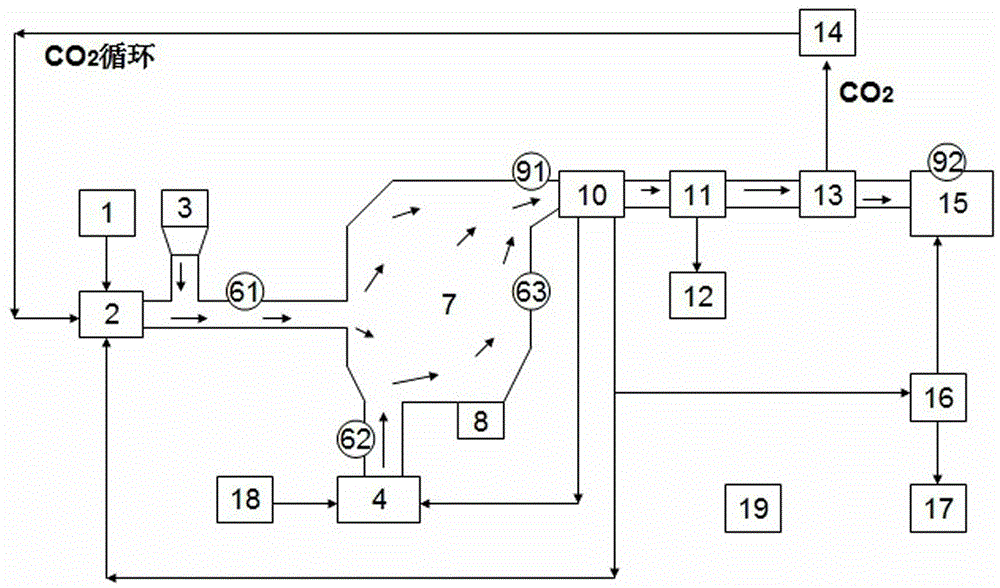

[0094] Embodiment 3: as image 3 As shown, the remote explosion-proof coalification carbon dioxide recycling hydrogen production device includes: backup power supply 1, CO 2 Tank 14, multi-plasma torch generator 2, intelligent coal feeder 3, solar steam generator 18, steam tank 4, reaction chamber 7, steam generator set 10, purifier 11, separator 13, solar electrolyzer 16, H 2 Tank 15, O 2 Tank 17, on-line detector I61, on-line detector II62, on-line detector III63, remote anti-riot device I91, remote anti-riot device II92, remote explosion-proof master control system 19; the backup power supply 1, CO 2 Tank 14, steam generator set 10 communicate with multi-plasma torch generator 2, solar steam generator 18 communicates with steam tank 4, described steam tank 4 communicates with the bottom of reaction chamber 7, multi-plasma torch generator 2 communicates with intelligent coal delivery The device 3 communicates with the reaction chamber 7 through a unique pipeline. The botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com