Fan mechanism of turbo-fan engine

A turbofan and engine technology, which is applied in the directions of machines/engines, liquid fuel engines, and components of pumping devices for elastic fluids, etc. Speed and air intake, reduce engine efficiency, etc., to achieve the effect of increasing jet pressure, large thrust, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

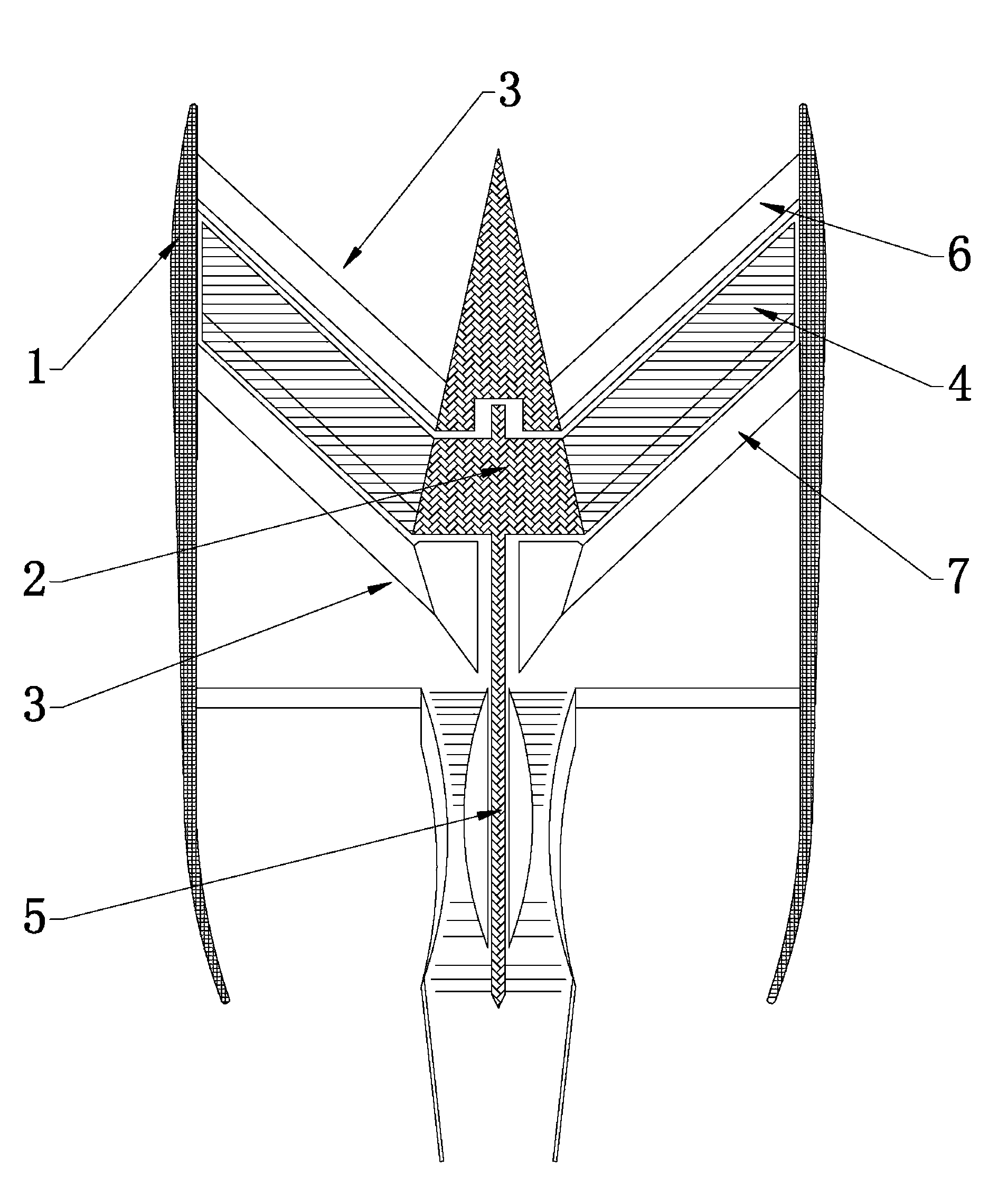

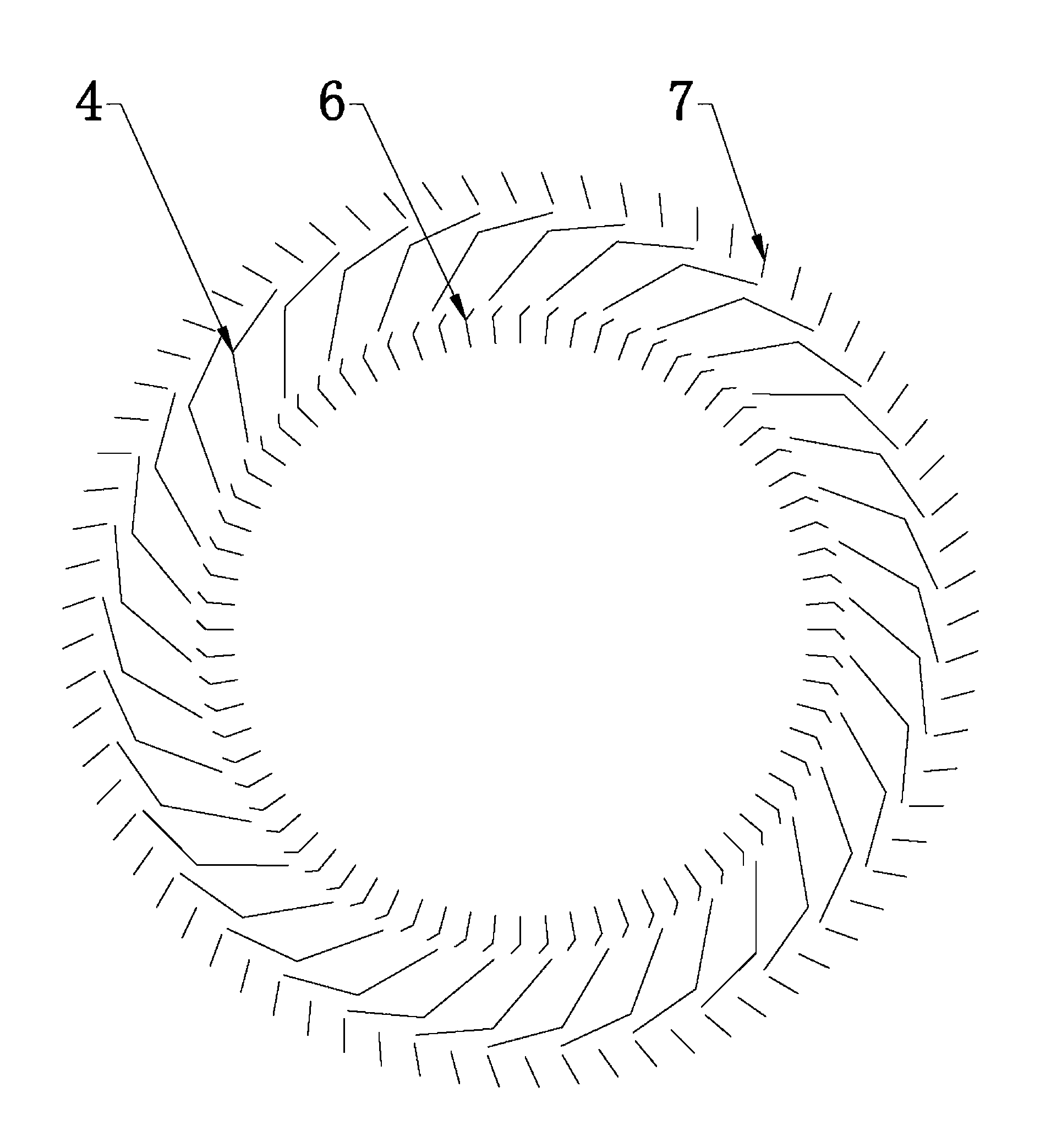

[0020] Such as Figure 1-2 Shown: a fan mechanism for a turbofan engine, including stator blades 3 fixed on the inner wall of the engine casing 1, rotor blades 4 fixedly connected to the blisk 2, the blisk 2 is connected to one end of the rotating shaft 5, wherein The stator blades 3 and the rotor blades 4 are distributed on the circumferential surface of the blisk 2 in a funnel shape as a whole, and the distribution density of the stator blades 3 is greater than that of the rotor blades 4. In the case of a change, the area of the blade air intake is greatly increased, that is, the working area of the stator blade 3 and the rotor blade 4 is increased. The stator vane 3 includes a stator guide vane 6 and a stator reverse thrust vane 7, the stator guide vane 6 and the stator reverse thrust vane 7 are respectively arranged on the outer side and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com